Watermarks are problematic for nanoelectronics industry. They can appear unexpectedly on wafers after each drying step even in an UltraClean process. Removing a water droplet requires non-negligible forces because the contact angle hysteresis generates a force in opposition with the motion. The spatial distribution of residues is correlated to the flfluid flflow, the stress development and the inner chemical reactions between surface and liquid. Isolating then characterizing the behavior of a water droplet and the chemical compounds left after its complete evaporation can reveal a likely source for these unwanted stains. Once the source is known then elimination of watermarks contamination becomes substantially easier. Since the probability of having watermarks increases with the wafer area, more stringent control of the drying step is required as the minimum feature length of ICs are reduced and wafer size gets bigger. Here, we present our preliminary study on the evaporation of millimetric droplets on silicon wafers. In the fifirst part, we propose a vapor-diffusion based theoretical model. In the second part, we confront our model to experiments and we investigate the different phenomena which inflfluence or intervene in the drying process of 2 sorts of silicon wafers (diluted HF - etched Si and oxidized Si).

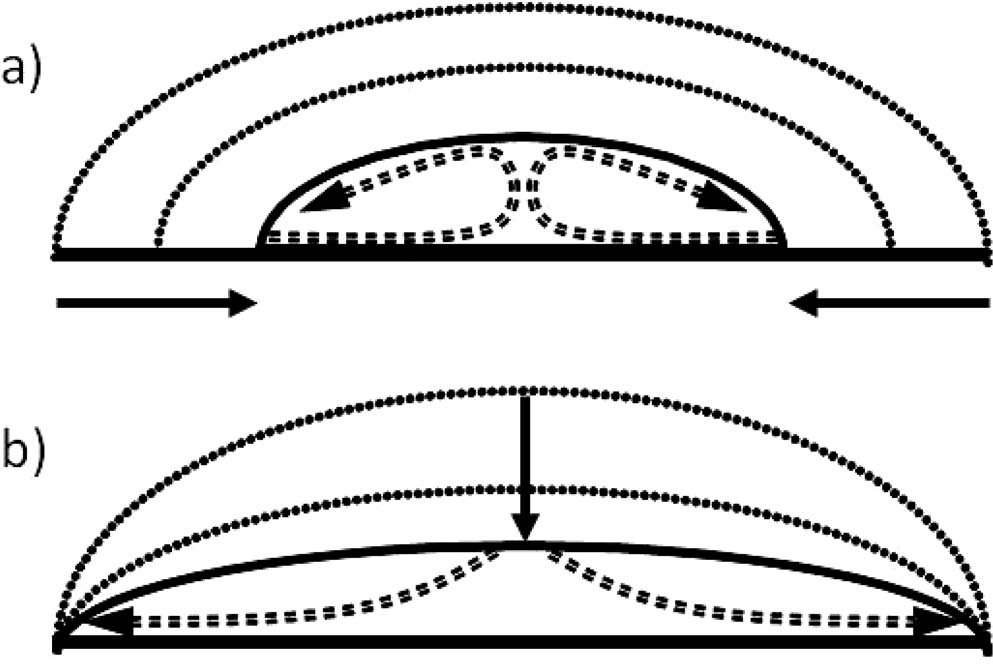

The Marangoni effect induces a flflow of liquid to areas where the value of the surface tension is highest. The surface tension increases with decreasing temperature, the flflow is directed to low temperatures. Ristenpart et al.14 then showed that depending on the value of the ratio of thermal conductivities of the substrate and the liquid, the direction of temperature gradient and by extension the Marangoni flflow direction may change. Few μPIV (Particles Imaging Velocity) studies15 report a radial flflow velocity in the range of few μm.s−1.

The radial flflow is responsible of the so-called “coffee-ring” stains left by colloidal solution after drying. The residues are carried by the radial streamlines to the contact line where they aggregate due to capillary and Van Der Waals forces. The shape of the colloidal deposit was obtained by numerical simulation by Morozumi et al.16 For that, initially, they obtained a profifile of evaporation rate from the numerical solution of heat transfer in between the drop and the substrate and the droplet and air. Then, knowing the gradient of the evaporation rate, they determined the drive speed of the particles from the balance sheet of solvent in the droplet and a slice. Finally by writing the conservation of particles, a sand dune-like profifile of the deposit was obtained. The peak density distribution at the edge explains the optical images of a dark ring on the edge and color much clearer in the center.

Evaporation: Model vs. Experiments.— All the experiments have been carried out in clean room class 1 where the relative humidity and temperature are fifixed to 40% and 22◦C. We used ultra pure deoxygenated water (1 ppb silica, 5 ppb oxygen, no trace of cationic salt) and 200 mm mirror polished silicon wafers. Hydrophobic surfaces were obtained by immersion for 5 min in 0.5% HF (dHF-etched Si). Hydrophilic surfaces were obtained by exposing such HF-treated surfaces to the clean room air during one day (Oxidized Si).

Unfortunately, the side-view CA tool cannot measure droplet characteristics with CA below 3◦. To see the complete evaporation and to probe the watermarks creation, a Nomarski differential interference contrast (DIC) microscope has been used to image the top-view of a millimetric droplet at a high contrast. We deposit 5 droplets randomly on 2 wafers with a volume in range of 50 nL-100 nL: the droplets 1 and 2 were dropped on a hydrophilic oxidized wafer (SiO2). Their initial footprints were both 1 mm large. The droplets 3, 4 and 5 were deposited on a hydrophobic dHF-etched wafer (Si). The initial diameters of their footprints were respectively 0.9 mm, 0.8 mm and 0.7 mm.

上一篇: 氧化 HF 溶液中硅的金属辅助化学蚀刻

下一篇: 单晶片清洁和干燥