1. Constant and Measurable Cup Exhaust.

It is recommended that the exhaust be on during all process steps. The exhaust must be high enough to evacuate the solvent vapor and to keep the mist, formed during the spin, below the plane of the wafer surface. The recommended exhaust flflow is 20mm-40mm H2O (25mm is typical). Different coaters may use different units to measure exhaust (i.e., mm Hg, or liters-per-minute). Regardless of the units on the gauge, a gauge is required to show relative exhaust changes. The exhaust must be kept constant to ensure process control and repeatability, because the exhaust impacts the spin cup ambient temperature, which in turn affects fifilm thickness. A warmer system can cause an increase in fifilm thickness.

2. Cabinet Exhaust.

The cabinet exhaust must be high enough to properly exhaust both the cabinet and the SOG delivery system. The cabinet exhaust must be high enough so that as the machine warms up, both the cabinet and the cup stay at the same temperature.

3. Programmable Spinner Cup Solvent Rinse Capabilities.

Spinner cup rinse is required to prevent SOG from drying on the inside of the cup and becoming a source for particles. Cups should be made of PVC or POLY because these materials wet well with cup-rinse solvents; good wetting ensures complete rinsing of the residual SOG, which lowers particle levels.

4. Adjustable Solvent Nozzle Capabilities.

The solvent nozzle tip should be adjustable for distance (vertical and horizontal) and direction/angle of dispense. An effective solvent rinse helps prevent particle formation.

5. SOG Handling System.

Recommended materials for the SOG delivery system are Teflflon, PTFE, PFA or polypropylene, which are compatible with highly polar organic solvents such as alcohols, ketones and esters. Delivery system components include cap adapters, system lines, O-rings, and the SOG bottles. The spinner cup and pressure bottle cap adapter need to be compatible with HF which is used to remove residues and particles. NOTE: Metal components should not directly contact the SOG.

6. Pressurized Dispense.

Pressurized dispense for SOG using helium instead of nitrogen is recommended. The helium molecule is less soluble in the SOG when under pressure. Therefore, it desorbs less, forming fewer bubbles than nitrogen during dispense and spin. Optimum control over dispense is achieved by using a precision 0-5 PSI regulator. Pressure canisters are not recommended. NOTE: Some manufacturers use nitrogen for this application with good results.

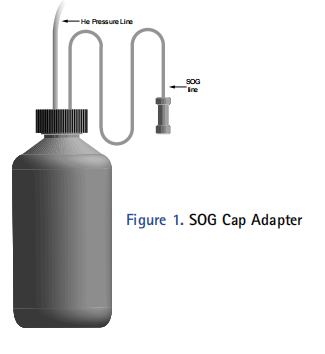

7. Cap Adapter.

The use of a special SOG cap adapter, available from Honeywell, (see fifigure 1) is recommended. The adapter allows pressurized helium dispense directly from the SOG bottle, therefore reducing the probability of solution evaporation, contamination, and particle formation. NOTE: A pressure certifified vessel to contain the SOG bottle may be required to meet local regulations).

Fig1

8. Chuck Material.

The chuck should be constructed from polypropylene, Delrin, P.E.E.K., or Kel-F and designed so that the memory of the chuck leaves no imprint on the wafer after the SOG deposition. NOTE: If thicker SOG is observed in the center of the wafer, the chuck may be too small relative to the wafer or not optimally designed.

9. Spin Ambient.

The recommended temperature and humidity for spin coating SOG is 70°±2° F, and, 35±3% relative humidity in the spin cup. Optimally the fab area for the spinner should also be controlled to these conditions. If the fab area cannot be well controlled, commercially available (i.e., SEMIFAB) temperature and humidity control chambers over the spinner cup have been shown to work successfully.

上一篇: 刷洗力的研究

下一篇: 无颗粒晶圆清洗干燥技术