ABSTRACT. Numerical analysis was performed to characterize the particle deposition behavior on a horizontal freestanding wafer with thermophoretic effect under the turbulent flow field. A low Reynolds number turbulent k-E model was used to analyze the turbulent flow field around the water. The deposition mechanisms considered were convection, Brownian and turbulent diffusion, sedimentation, and thermophoresis. The averaged particle deposition velocities and their radial distributions for both the upper and lower surfaces of the wafer were calculated from the particle concentration equation in an Eulerian frame of reference. When the wafer is unheated, in the diffusion-controlleddeposition regime with particle size d, < 0.1 pm the averaged particle deposition velocity under the turbulent flow was about 1.3 times higher than the laminar flow case, and the local deposition velocity near the center of the wafer was high equivalent to that near the edge. The particle deposition on the lower surface was comparable to that on the upper surface. When heated, the deposition-free zone, where the deposition velocity is lower than lo-' cm/s, exists between 0.096 pm and 1.6 pm with AT of 10K, indicating shifting behavior to larger size range compared with the laminar flow case. As for the local deposition velocities, for dp < 0.05 pm, the deposition velocity is higher near the center of the wafer than near the wafer edge, whereas for dp=2.0 pm the deposition takes place mainly on the inside area of the wafer. The comparison of the present numerical results with the experimental data by Ye et al. (1991) showed reasonably good agreement. Finally, an approximate deposition velocity model was suggested. The comparison of the model calculations with the present numerical results and the experimental data of Opiolka et al. (1994) showed good agreement. AEROSOL SCIENCE AND TECHNOLOGY 25: 141- 156 (1996).

Particle deposition on semiconductor wafers is an important problem in VLSI circuit manufacturing. For this reason so far much effort has been devoted to reducing the contaminant levels in clean rooms and in the VLSI manufacturing equipment. In order to understand and develop strategies for minimizing particle deposition it is necessary to characterize the flow field around the wafer and investigate various transport mechanisms. Theoretical and experimental works concerned with this subject before 1990 were summarized by Pui et al. (1990). Since then several research works for reducing particle deposition onto a wafer by using thermophoresis have been progressed theoretically and experimentally (Opiolka et al., 1990, 1994; Ye et al., 1991). Recently, Fujii et al. (1989) and Pui et al. (1991) reported the existence of flow fluctuations in the vicinity of the wafer produced by filter media and other obstructions in the clean rooms; however, none of the existing theoretical studies on particle deposition onto a wafer is sufficiently detailed to allow the understanding of particle transport and deposition behaviors around the wafer under the turbulent flow field. Therefore, effects of turbulence on particle deposition onto a wafer deserve examining.

The deposition mechanisms related to particles are diffusion, convection, sedimentation, inertia, thermophoresis, electrostatic force, and turbulence. It is generally known that there is not enough information about the charge distribution of clean room particles to evaluate the exact influence of electrostatic forces on particle flux. In this work, the particle deposition onto a horizontal freestanding wafer was studied numerically under the turbulent flow field similar to that reported recently in the clean room. In addition, sedimentation and thermophoresis were also considered. In order to predict the turbulent flow field around the wafer, a low Reynolds number k-s turbulence model was used in the analysis. This model allows the facility on the treatment of the very thin particle concentration boundary layer due to high Schmidt number of particles. Both average and local deposition velocities were calculated and discussed in detail. The averaged deposition velocity were compared with laminar flow results, those of the available experimental data. Finally, an approximate deposition velocity model is suggested. The results of our suggested model are compared with the present numerical results, those of the existing model and the available experimental data.

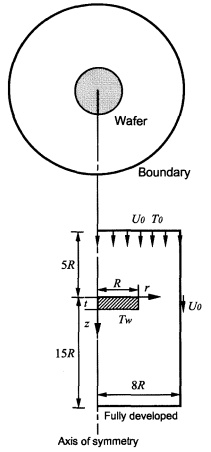

Fig1

The SIMPLE algorithm by Patankar (1980) was modified to consider the particle transport including the migration due to the external force fields as pointed out by Stratmann and Whitby (1989). The velocity and temperature fields of the fluid were calculated first using the momentum and energy conservation equations of the fluid Eqs. 6-14, and these calculated values were then used as input for the convective-diffusion equation Eq. 4. Finally, the related particle deposition velocities were calculated for the upper and the lower sides of the wafer.

The calculation grid system introduced here consists of 175 (axial) X 104 (radial) grid lines. The grid test was carried out for the laminar flow including thermophoresis and sedimentation before starting the main calculation, an the calculated results for AT = 10K, where AT = T, - To, were shown in Figure 2 with the grid spacings 100, 25, 10, and 5 prn for the test. The experimental results of Ye et al. (1991) were also shown for comparison. It is noted that the numerical results are very sensitive to the grid spacing between the nearest grid and the wall of the wafer. It can be seen that for d, < 1 pm, the deposition velocities for the grid spacing of 100 Fm overestimate those of the 10 pm grid spacing largely, but in the cases of the grid spacings of 10 and 5 pm, the deposition velocities are the same. In the present work, the first grids from the surface of the wafer in all directions were located at the distance of 10 pm, and the other grids were arranged to increase geometrically with geometric ratios less than 1.2.

下一篇: 掺杂 Mg 的ZnO薄膜的沉积和湿法蚀刻