Abstract: In this study, to fabricate diamond concave microlenses in a simple manner, an approach that combines a spin coating process with subsequent dry etching was demonstrated. First, photolithography was used to produce cylindrical holes in the photoresist layer on the diamond surface. Then, another photoresist was spin coated to fifill the holes, and the concave structures with meniscus shapes were then obtained because of centrifugal force and interfacial tension. Finally, diamond concave microlenses were formed by transferring photoresist concave structures onto a diamond substrate using a dry etching technique. The fabricated diamond microlens exhibits a low surface roughness with nanometers as well as high-quality imaging and focusing performances, which is expected to have a wider range of potential applications under harsh and special conditions.

In this study, we proposed a simple approach to fabricate concave microlenses on a diamond. This approach includes spin coating process to form photoresist concave structures and dry etching technique to transfer the concave patterns onto diamond surface. Qiao Xu et al. presented a method for realizing polymer concave microlenses by spinning the acrylate resin over the modifified and solidifified polydimethylsiloxane holes . However, acrylate resin is not resistant to etch. In our work, we used photoresist to form concave structures by the effffect of interfacial tension and centrifugal force. After fabrication, the morphology and the optical performance of diamond concave microlenses were characterized. The fabricated microlens showed a spherical profifile with a low surface roughness and performed well in basic imaging and focusing tests.

The sample used in this study was a high-pressure and high-temperature (001) Ib single crystal diamond substrate with a dimension of 3 × 3 × 0.4 mm3 . The fabrication of microlenses on a diamond substrate is graphically illustrated in Fig. 1. First, a thick layer of SPR 220-7.0 photoresist was twice coated on the diamond substrate with a spin speed of 2000 rpm, resulting in a photoresist thickness of approximately 17 µm. Second, cylindrical holes were generated by photolithography in the photoresist layer with diameters of 100 µm and a center distance between adjacent holes of 140 µm. Some photoresist remained on the diamond substrate in the hole areas after photolithography, resulting in holes with depths of 14 µm. Third, the hole structures were fifilled with AZ 5214 photoresist and spun at a speed of 5000 rpm. Through the effffects of centrifugal force and interfacial tension, concave structures with meniscus shapes were obtained. Finally, through an inductively coupled plasma (ICP) etching process, the photoresist concave structures were transferred onto the diamond substrate. The ICP processing conditions were: 450 W ICP coil power and 23 W bias power. The etching gas was a mixture of O2 and Ar with flflow rates of 40 and 15 sccm, respectively.

The geometries and properties of the photoresist and diamond concave microstructures were characterized using various methods. Figure 2 shows a 2D image from an optical microscope (OM) (Olympus, BX-51) and a cross-section profifile from a stylus profifiler (DEKTAK-XT) of the photoresist concave structures obtained after the second spin coating process. The accuracy of OM is greater than or equal to 1 µm, and the vertical resolution of stylus profifiler is 0.1 nm. During the second spin coating process, the AZ 5214 photoresist was spin coated and some of it reflflowed to the thick regions between the holes due to the effffect of interfacial tension between the two difffferent photoresist layers. Therefore, it appears in Fig. 2(a) that the concave structures with meniscus shapes are closely arranged. Nevertheless, the surfaces in the regions between the holes do not fifit the spherical surfaces. Therefore, it is considered that the hole areas within the white dot circle line in Fig. 2(a) are the regions of concave spherical structures. The cross-sectional profifile was measured at the center of the concave structure with a length of approximately 100 µm (along the black dot-dashed line in Fig. 2(a)), which conformed well to a spherical curve with a depth of 2.21 µm and a radius of curvature (ROC) of 565 µm (as shown by the fifitted red line). The depth is related to the depth of hole in the fifirst photoresist layer, which would be affffected by the thickness of the fifirst photoresist layer and thickness of residual photoresist. Difffferent concentration and viscosity of photoresist cause difffferent interfacial tension between layers. The spin coating speed will affffect the centrifugal force. Thus, concave structures with difffferent depths and ROCs can be fabricated by changing the depth of fifirst photoresist layer, concentration and viscosity of photoresist and spin coating speed during the second spin coating process.

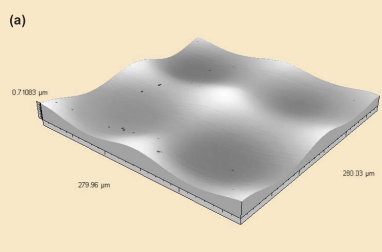

To obtain concave microlenses on a diamond, ICP etching was used to transfer photoresist concave structures onto the diamond substrate. The diamond substrate was loaded on a holder cooled with circulating purifified water to maintain the sample temperature at approximately 20 ◦C, thereby avoiding deformation of the photoresist concave structure mask, which might otherwise be caused by excess heat accumulation. Figure 3 shows 3D images and the cross-sectional profifile by a white light interferometer (CCI 6000, Talysurf) with vertical resolution of 0.01 nm. As Fig. 3(c) shows, the diameter and depth of the diamond concave microlens were 100 µm and 198 nm, respectively, indicating a low etch selectivity (defifined as the ratio of diamond etch rate to that of photoresist) of 0.090. This low etch selectivity manifests in diffiffifficulties in processing diamond because of its hardness and chemical inertness. The cross-sectional profifile was circle fifitted with an ROC of 6000 µm and is indicated in the red line plot as well. According to the theory of geometrical optics, the focal length (f) and numerical aperture (NA) of a spherical concave microlens can be calculated, where f and NA are determined by Eqs. (1) and (2), respectively, when the latter is small .

Fig1

The low surface roughness is an essential standard for optical devices. Therefore, a lower bias power of 23 W was chosen to reduce the defects caused by the ion bombardment in the ICP etching process [29]. The root-mean-square values of surface roughness of three randomly selected 10 × 10 µm2 areas were all less than 1.5 nm measured by atomic force microscopy (Innova), which satisfifies the requirement of optical applications. To eliminate the inflfluence of the surface curvature, the results were obtained after a flflattening operation (where the curved surface as the reference background was subtracted).

上一篇: 晶圆级微透镜阵列的设计与制造

下一篇: 醇碱溶液中多孔硅的化学氧化