We have investigated the formation of large-grained polycrystalline silicon (poly-Si) films on glass for thin-film solar cells using the ‘seed layer concept’ which is based on the epitaxial thickening of a thin large-grained poly-Si template (seed layer). Due to the glass substrate all process steps are limited to a temperature of about 600 °C. The aluminium-induced layer exchange (ALILE) process based on the aluminium-induced crystallisation (AIC) of amorphous Si has been used to prepare p+ -type seed layers featuring large grains and a high preferential (100) orientation of the surface. The seed layers have been thickened by electron cyclotron resonance chemical vapour deposition (ECRCVD) to form the p-type absorber of the solar cell. First poly-Si thin-film solar cell structures have been prepared by deposition of an n+ -type a-Si:H emitter. So far an open circuit voltage of 284 mV has been reached without any additional treatments like defect annealing and defect passivation.

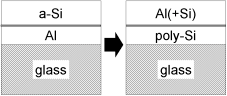

In this section the seed layer formation by the aluminium-induced layer exchange (ALILE) process is described. The process is based on the aluminium-induced crystallisation (AIC) of amorphous Si. The starting point for the ALILE process is a glass/Al/a-Si stack. For our experiments we have used cleaned glass substrates (Corning 1737F). Both layers (Al and a- Si) have been deposited in the same chamber by dc magnetron sputtering. The ALILE process requires a thin permeable membrane between the Al and the a-Si layer which controls the diffusion of Al and Si [13]. Usually the membrane consists of an Al oxide layer formed by exposure to air of the Al-coated glass substrate prior to the a-Si deposition. Our standard oxidation time is 2 hours. The thickness of the deposited films is about 300 nm and 375 nm for Al and a-Si, respectively. The excess of Si compared to Al is necessary for the preparation of continuous poly-Si films on the glass substrate. Annealing of the initial glass/Al/a-Si stack at temperatures below the eutectic temperature of the Al/Si system (Teu = 577 °C) leads to a layer exchange and a concurrent crystallisation of Si resulting in a glass/poly-Si/Al(+Si) stack (Fig. 2). The membrane stays in place during the entire ALILE process (indicated by a grey line in Fig. 2). Thus, the thickness of the resulting poly-Si film (seed layer) is determined by the thickness of the initial Al layer. The Al layer on top of the seed layer contains some Si inclusions (‘Si islands’).

The ALILE process starts with the diffusion of Si across the permeable membrane into the Al layer. This leads to an increase of the Si concentration within the Al layer until the critical concentration for nucleation is reached. Then, Si nuclei are formed within the Al layer. These nuclei grow in all directions until they are confined vertically between the glass substrate and the permeable membrane. Afterwards the growth continues laterally only. The continuous formation of new nuclei and their growth reduces the Si concentration until it drops below the critical concentration for nucleation. By this mechanism further nucleation is suppressed such that the final poly-Si films feature large grains. Due to the fact that the Al layer is still supersaturated (i.e. the Si concentration exceeds the saturation concentration) the growth of existing grains continues in lateral direction until adjacent grains touch each other and finally form a continuous large-grained poly-Si film on the glass substrate. Using the Al/Si phasediagram and thermodynamic considerations the ALILE process and especially the suppression of nucleation as a characteristic feature can be understood.

Fig1

Figure 10 shows the concentration of boron (CB) and aluminium (CAl) within this sample. The depth profiles have been measured using secondary ion mass spectrometry (SIMS). Light and deep grey correspond to absorber layer and seed layer, respectively. At [B2H6]/[SiH4] = 200 ppm the boron concentration within the absorber layer is about 2-3 x 1018 cm-3. However, the effective doping level obtained by capacitance-voltage (C-V) measurements (using a Schottky diode) is only about 3 x 1015 cm-3. The large difference is probably caused by a low doping efficiency (inactive boron atoms) and the compensation of the n-type behaviour usually observed for samples without boron doping. The boron concentration increases towards the glass substrate due to boron diffusion out of the glass substrate. Roughly the same behaviour has been observed for the aluminium concentration (the seed layer and the glass substrate act as a source for aluminium diffusion into the absorber layer). However, the aluminium concentration within the main part of the grown film is below the detection limit of about 1015 cm-3. Consequently the diffusion of aluminium should not pose a problem for the solar cells.

上一篇: 硅的低温表面清洗及其在硅MBE中的应用