A low temperature thermal cleaning method for Si molecular beam epitaxy (MBE) is proposed. This method consists of wet chemical treatment to eliminate carbon contaminants on Si substrates, thin oxide film formation to protect the clean Si surface from contamination during processing before MBE growth, and desorption of the thin oxide film under UHV. The passivative oxide can be removed at temperatures below 800~ It is confirmed that Si epitaxial growth can take place on substrates cleaned by this method and that high quality Si layers with dislocations of fewer than 100/cm ~ and high mobility comparable to good bulk materials are formed. Surface cleanliness, the nature of thin passivative oxide films, and cleaning processes are also studied by using such surface analytic methods as Auger elec tron spectroscopy, reflection high energy electron diffraction, and x-ray photoelectron spectroscopy.

Si molecular beam epitaxy (Si-MBE) has been shown to produce device quality epitaxial Si films. This can, however, be obtained only when a clean silicon substrate surface is prepared before epitaxial growth. That is, contaminants on the substrate, such as oxide and carbide, prevent layer growth and become the main causes of crystal defects in the epitaxial layers. In order to provide clean surfaces and eliminate defect origins at interfaces, high temperature thermal etching at about 1200~ prior to epitaxial growth has been commonly used in an ultrahigh vacuum (UHV) (1-5). However, this technique causes undesirable impurity diffusion and changes the designed impurity concentration profile within th.e Si substrate. Furthermore, crystal defects, such as dislocations and stacking faults, tend to increase and slip lines are often generated across the Si substrate during high temperature treatment. Thus, it is important to find a low temperature surface cleaning method in which the temperature can be lowered to below 900℃.

In order to overcome the drawbacks of these low temperature surface cleaning methods, a new surface cleaning method was proposed by the authors and preliminary results were reported (12). In this paper, the details of this method are described, and characterization of the cleaned Si substrates and the epitaxial films grown on the cleaned substrates is also reported. This low temperature cleaning method consists of two processes. Wet chemical treatment is the first process and is done for etching the contaminated surface layers and for formation of a contamination-free passivative oxide film on the Si substrate. The second process is heating under UHV at temperatures below 900~ to remove the oxide film through thermal etching and obtain an atomically clean surface.

This surface cleaning method is thought to also be very useful for basic studies of Si surfaces. This is because the thermal stress and formation of thermal etch pits during the cleaning process are rnueh less than that for the high temperature method which has been commonly used in the field of surface physics and chemistry.

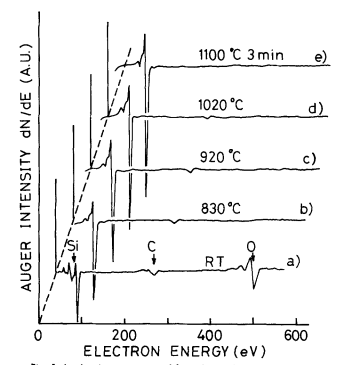

Fig1

After chemical treatment, the sample was mounted very loosely between densified high purity graphite rings situated on the Ta heater assembly. Any direct contact between the sample and the metal components was avoided to prevent reaction between the Si and the metals. A loose holding prevents generation of slip lines from the contacts. The sample holder was then loaded into a commercial MBE instrument (Vacuum Generators, Model 366) consisting of a three-chamber system composed of a first entry lock, an analysis chamber, and a growth chamber. The base pressure of the growth chamber was lowered to about 2 x 10-" torr by using diffusion pumps, Ti sublimation pumps, and liquid nitrogen cryo-panels.