A number of wafer cleaning technologies compete for the use in high efficiency solar cell processing. Some are borrowed from IC manufacturing, e.g. the well-known RCA cleaning, the H2SO4 /H2O2 based SPM clean, and the ozone-based HF/O3 clean, others were especially developed for solar cell processing such as the BASF Seluris® C cleaning approach. In this work the mentioned technologies are compared qualitatively, and the latter three are compared experimentally in terms of cleaning efficiency and suitability as pre-diffusion cleans for industrial application in the field of processing bifacial and IBC n-type solar cells with efficiencies exceeding 21 %. It is found that all three cleaning recipes reduce metal contamination from values up to 1E15 atoms/cm2 down to the level of 2-3E11 atoms/cm2 . Both, the Seluris® C clean and HF/O3 clean perform similar as the reference in use (SPM clean). The suitability for mass production of the two procedures was tested by artificial bath aging (by spiking with Fe and Cu according to an enrichment simulation), and testing these baths in terms of outplating and cleaning efficiency. Threshold contamination levels were determined by measuring implied Voc values after boron and phosphorus diffusion of intentionally contaminated wafers. Cell precursor lifetime samples were manufactured and good results with the tested, industrially applicable cleaning methods were obtained. Keywords: wafer cleaning, n-type, ICP-MS, metal surface contamination.

It is generally assumed that high efficiency solar cell devices such as PERC cells, bifacial n-type solar cells such as the ISC’s BiSoN concept and interdigitated back contact (IBC) solar cells such as the ISC’s ZEBRA concept require more advanced wafer cleaning than standard aluminium back surface field solar cells. Cell efficiencies around 20% (BiSoN) and above 21% (ZEBRA) can only be achieved with sufficiently clean surfaces before high temperature steps. For industrial implementation of such solar cell concepts straight forward and cost-efficient high throughput cleaning techniques are required.

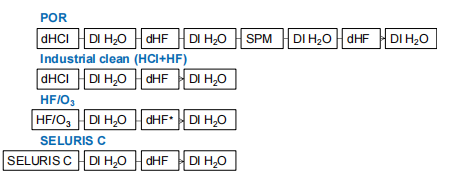

In a first experiment four different cleaning procedures were compared: the current ISC Konstanz standard clean for high efficiency solar cells, our process of record (POR), the HF/O3 clean,the BASF Seluris® C clean, and an industrial clean (HCl+HF). The cleaning baths were freshly made up and tested on alkaline textured wafers and cleaning efficiencies were determined by measuring the metal surface contamination using the Sandwich-Etch-ICP-MS method.

Fig1

To determine the impact of bath aging on the wafer surface concentration, freshly made up cleaning baths were spiked using Cu and Fe standard solutions (1000g/L, AAS standard solution in 2% HNO3 , Carl Roth). For the first measuring point an equivalent of 5 ppb Fe/Cu were added, 50 for the second, and 250 for the third (resulting in 5, 55, and 305 ppb in the bath). SPM cleaned wafers were immersed into the spiked cleaning baths for 5 min (Seluris® C) and 10 min (HF/O3 ), respectively. Wafers were rinsed with water before the metal surface contamination was extracted for ICP-MS analysis. The resulting Cu and Fe concentrations on the wafer surfaces can be found in Fig. 5.

No significant contamination of the clean wafer surfaces after immersion in spiked cleaning baths could be measured for the Seluris® cleaning bath, whereas the HF/O3 cleaning bath had an increasing tendency for Fe contamination from the bath (“outplating”) and a strong tendency for Cu outplating at the highest contamination level. This also has an impact on the cleaning efficiency on alkaline non-cleaned textured wafers. In Fig. 6 we show that the efficiency for Cu removal of the HF/O3 bath deteriorates with bath aging, probably due to the outplating effect, whereas no impact on the Seluris® C can be detected. These results show that the assumed feed+bleed conditions for the Seluris® C bath are well suited for mass production. The HF/O3 bath, however, might need different feed+bleed settings (replacement of larger volumes of cleaning liquid) to maintain low metal concentrations in the bath and hence good cleaning efficiency.

High efficiency cell processes require more advanced cleaning. However, cleaning needs to be simple and cost effective. Two alternatives were shown to be suitable for mass production. Threshold Cu surface concentrations before the diffusion steps of ISC Konstanz’ standard process for high efficiency bifacial n-type solar cells (BiSoN) were deduced from experimental results and found to be in the range of 1E12 atoms/cm2.

上一篇: 半导体晶圆清洗站多化学品供应系统的讨论

下一篇: 使用超临界二氧化碳进行精密表面清洁