Recently, CMOS devices are fabricated, in some cases, by performing ion implantation through a mask of KrF resist film to form p- and n-wells. As the size of resist patterns is reduced, more attention is paid to ArF resist films. For further miniaturization, ArF immersion lithography is proposed. The substrate surface must be bare in spaces of a resist film before ion implantation can be carried out. This is because if a bottom antireflection coating (BARC) layer is present below the resist film, ions are trapped by the BARC layer. However, if the photoresist film is patterned in the absence of BARC layer, standing waves are generated due to substrate reflection, resulting in substantial corrugations in the sidewall of resist pattern after development. For the purpose of smoothing out a corrugated profile due to standing waves, it is believed effective to use a photoacid generator (PAG) capable of generating a low molecular weight acid amenable to more acid diffusion or to apply high-temperature PEB because acid diffusion is enhanced by either means. In the size range of 200 to 300 nm where the resist film for ion implantation is resolved by KrF lithography, resolution is not degraded by the enhancement of acid diffusion. In the size range of less than 200 nm where the resist film for ion implantation is resolved by ArF lithography, however, the enhancement of acid diffusion is undesirable because resolution is degraded or proximity bias is enlarged by acid diffusion.

It was contemplated that the substrate surface to be ion implanted is made bare by placing a BARC film as a layer beneath a resist film, developing the resist film to form a resist pattern, and dry etching the BARC film with the resist pattern made mask. In this approach, soft dry etching is employed so that the substrate may not be altered, for the reason that if the substrate is oxidized to form an oxide layer, ions can be trapped by this portion. Specifically, dry etching with hydrogen gas is used because the substrate can be oxidized by dry etching with oxygen gas. Then a BARC having a high dry etching rate with hydrogen gas is required.

A dyed resist material is the most traditional technique, which is based on the concept that a photoresist film itself is made absorptive for preventing generation of standing waves, and has been investigated since the age of i or g-line novolak resist materials. As the absorptive component used in ArF lithography, a study was made on a base polymer having benzene ring introduced therein or an additive having benzene ring. However, the absorptive component is insufficient to completely prevent standing waves. Increased absorption is effective for reducing standing waves, but gives rise to the problem that the resist pattern becomes tapered, i.e., of trapezoidal profile in cross section.

Fig1

More preferably, the alkaline water contains 1 to 99% by weight of at least one member selected from the group consisting of ammonia, ammonia hydrogen peroxide water, tetramethylammonium hydroxide, tetraethylammonium hydroxide, tetrapropylammonium hydroxide, tetrabutylammonium hydroxide, choline hydroxide, benzyltrimethylammonium hydroxide, benzyltriethylammonium hydroxide, DBU, DBN, hydroxylamine, 1-butyl-1-methylpyrrolidinium hydroxide, 1- propyl-1-methylpyrrolidinium hydroxide, 1-butyl-1-methylpiperidinium hydroxide, 1-propyl-1-methylpiperidinium hydroxide, mepiquathydroxide, trimethylsulfonium hydroxide, hydrazines, ethylenediamines, and guanidines.

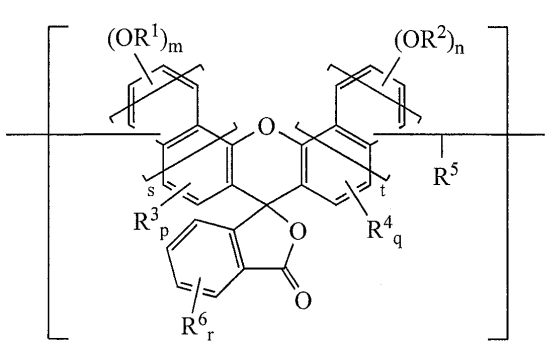

When a pattern is formed in a substrate by ion implantation, there is a need for an underlayer film which is strippable without causing damage to the ion implanted substrate. Ideal for the purpose of forming a satisfactory pattern even on an irregular substrate surface by lithography is the trilayer process involving coating a thick underlayer film to flatten the topography of the substrate, and coating a light-absorptive silicon-containing intermediate film thereon whereby the two-layer antireflection coating minimizes substrate reflection. However, after ions are implanted through the pattern formed by the trilayer process, it is difficult to strip the trilayer without causing damage to the ion implanted substrate. In contrast, the resist underlayer film-forming composition of the invention is strippable with alkaline water. A novolak resin comprising recurring units of fluorescein is hydrolyzed in alkaline water to generate a carboxyl group so that the resin turns soluble in alkaline aqueous solution. Thus the underlayer film can be stripped without causing damage to the ion implanted Si or SiO2 substrate.

上一篇: 低温对湿蚀刻法制备微环谐振器的影响

下一篇: 在制造过程中去除氮化硅和其他材料的方法