In the present work, alumina gel was developed for passivating silicon wafers. The alumina gel was prepared by sol–gel method with aluminum sec-butoxide as precursor. After coating, rapid thermal process (RTP) was conducted to activate the passivation efect. X-ray photoelectron spectroscopy and C–V curve were executed to evaluate flm properties. The peak at 74.35 eV confrmed the formation of Al2O3. Meanwhile, a small peak at low binding energy decreased with the growth of annealing temperature, which was ascribed to the escape of hydrogen, leading to the decline of efective lifetime after 700 °C. The highest fxed charge (Qf ) of −1.16e12 cm−2 and superior interface defect density at mid gap (Dit) of 1.98e12 cm−2eV−1 were obtained at the annealing temperature of 700 °C, contributing to the highest efective minority carrier lifetime of 292 µs. The present work will be helpful to provide a more cost-efective technique for Al2O3 passivation.

In order to suppress the recombination in wafer surface, many passivation flms, including TiO2, SiO2, SiNx, and Al2O3, have been presented . Among them, Al2O3 has been widely applied for the back-surface passivation in industrial passivated emitter and rear cell (PERC) benefting from the superior surface chemical passivation as well as the feld efect passivation induced by the fxed negative density .

The sol–gel synthetic technique has been applied for fabricating Al2O3 flm by some researchers. Two routes for fabricating sol–gel are generally described in the document, which are polymeric sol–gel route and colloidal sol–gel route. The former is utilizing the chemistry of metal–organic precursors in organic solvents, while the latter is applied colloidal chemistry in aqueous media. Notice that polymeric sol–gel route is much better suited for the multiple components membrane. Sol–gel method was also applied to fabricate alumina gel in this paper, but instead of environmentally hazardous organic solvents water was imported as the solvent. Considering the alumina precursor, aluminum isopropoxide is a common option ; however, the relative low water solubility of aluminum isopropoxide can lead to unmanageable transparency and particle size of the alumina gel. Aluminum sec-butoxide becomes an interesting alternative due to the superior water solubility.

Fig1

As to the remarkable decline of Al 2p, O 1s, and C 1s signal, we surmise that the high temperature accelerates the evaporation speed of gel containing organic constituent required to transform to gas state taking away organic Al and the declining leads to the decreasing of efective lifetime.

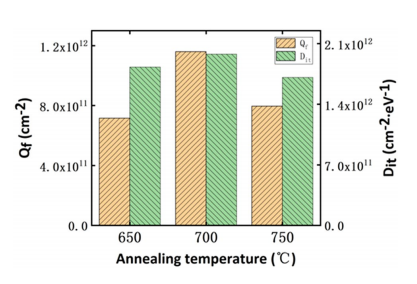

Figure 6 clearly shows that all three samples exhibited a relatively large fxed charge density over −7.16e11 cm−2. Also, the maximum fxed negative charge occurred at 700 °C, with a Dit of 1.98e12 cm−2 eV−1 , indicating the most excellent passivation efect. The XPS measurement, the efective carrier lifetime results, as well as the C–V curves present consistent evidence that the passivation efect of alumina gel is optimized at the annealing temperature of 700 °C.

A study on the alumina flms prepared by sol–gel method and their performance on the passivation of silicon wafer is accomplished. Aluminum sec-butoxide was used as an alumina source to make alumina passivation flms on the silicon wafers. Surface passivation quality as a function of annealing temperature is studied by the efective lifetime and negative fxed charge density. In this case, a low temperature appears not to provide enough energy to activate the passivation, while the passivation was considerably improved with the rising of temperature beneftting from the enhancement of feld efect. After annealing at 700 °C, the flm shows a sufciently large amount of fxed charge density (Qf = − 1.16e12 cm−2); at the same time, the amount of interface state density (Dit = 1.98e12 cm−2 eV−1) inhibits the passivation efect of the flm. Improving the passivation quality of spin-coating flms as good as the flms prepared by PECVD or ALD methods is the next step in the future.

上一篇: 快速热化学气相沉积设备中硅片的热分布评估