Solution growth continues to be one of the most powerful techniques for the production of single crystals for basic and appliedresearch. It is a versatile technique that allows for the growth of congruently andincongruently melting materials with equal ease. The primary requirement for growth is that there be an exposedprimary solidifification surface in the appropriate equilibrium alloy phase diagram. In this paper, we will review some of the systems that we have appliedthis technique to over the past several years. These range from binary andternary intermetallic compounds such as RFe2 (R=Rare earth) and RT2Ge2 (T=Ni andCu) to the refractory RNi2B2C family of magnetic superconductors to several families of quasicrystals. In each case, specifific nuances of the relatively simple growth technique will be discussed.

Single crystal samples allow for the measurement of the intrinsic properties of materials. In specifific, they generally provide samples with less strain, higher purity, fewer grain boundaries, and natural growth habit. For basic studies of the electronic, magnetic, thermodynamic and structural properties of new or exotic materials the size of single crystals requiredrarely exceeds a cubic centimeter andoften (with the exception of inelastic neutron scattering) crystals with dimensions of several mm on a side are more than adequate. Given that the majority of materials are incongruently melting, a technique that can grow a wide variety of congruently and incongruently melting materials with equal ease, with relatively simple equipment, in rather short time scales, is of great desirability. Growth from high-temperature metallic solutions is just such a technique. In addition it uses relatively small amounts of materials, making it much more economic than techniques such as Bridgman or Czochralski (CZ) growth, both of which require more substantial quantities raw material.

In this paper, we will review several recent examples of single crystals (or quasicrystals) that have been grown from metallic solutions. The emphasis will be on showing the versatility of this technique as well as highlighting advances that have been made in temperature range, flflux, or crucible design over the past decade. This paper shouldbe consideredas an extension of two earlier papers publishedon this technique by Fisk and Remieka , andCanfifieldandFisk.

Growth of single crystals from metallic solutions requires very simple equipment: box andvertical tube furnaces, a glass bench for evacuating and sealing quartz tubes, crucible materials and, in some cases, an arcmelter for pre-alloying elements andfor working with Ta. Many of these details have been coveredin the earlier two articles andwill not be reviewedhere.

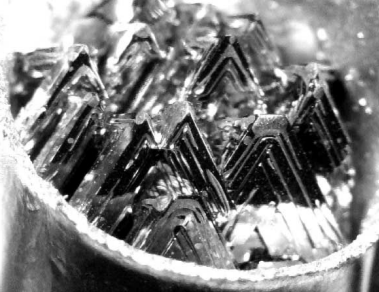

Elemental Ce andFe are combinedin an Ce0.55Fe0.45 atomic ratio in the lower part of a Ta 3-cap crucible which itself is sealedinto a quartz ampule. The ampule is placedin a box furnace, heatedto 1100℃ andthen slowly cooled to 950℃ over 100–200 h. When the slow cool is completedthe ampule is invertedandthe excess liquid is decanted. RFe2 single crystals grow with well developed facets (see Fig. 1 for GdFe2). Neutron diffffraction on samples as large as several grams reveals that the crystals have diffffraction peak line widths below instrumental resolution. In a similar manner, single crystals of RAl3, RIn3, RSb2, RBi2, andmany other binary compounds can be grown from binary melts.

Fig1

The growth of icosahedral Al71Pd21Mn8 (I-AlPdMn) is conceptually similar to the growth of I-RMgZn described above, but the primary solidifification surface is signifificantly smaller and the material is much closer to being congruently melting . An initial composition of Al73Pd19Mn8 is heatedto 875℃ andslowly cooledto 840℃ over up to 100 h. Single grains of I-AlPdMn are similar in morphology to I-RMgZn but have linear dimensions that can exceed several cm. What is truly remarkable about the growth of these quasicrystals is that even though there is no attempt to control nucleation, andeven though the initial concentration is very close to the actual concentration of the solidphase, only one or two nucleation sites occurs in a given growth. This leads to the ability to grow extremely large single grains, often crucible limitedin 5, 10 and20 ml Al2O3 crucibles. This observation is consistent with there being a relatively large energetic cost to forming a nucleation center.

Orson Welles once saidthat making fifilms was like being a small childwith a very expensive paint box. In a similar manner searching for new materials andgrowing single crystals of a wide variety of compounds requires a adequate and flflexible materials budget. We gratefully acknowledge the US Department of Energy, Offiffiffice of Basic Energy Sciences. Their unflflagging support has made all of this research possible.