Recent trends and progresses in power electronics rely on fast, miniaturized, high current and high temperature switching semiconductors. However, in electronics system design, passive components technologies, in particular capacitors, limit their full exploitation. The goal of the present paper is, firstly, to analyse the capacitor technologies, in particular ceramic technologies for the limits set by high current, high voltages, high temperatures, high frequencies, and by cost items. Secondly, for each of the identified limits, to define the tools and technologies that are capable to overcome it. The new technologies include a new PLZT based antiferroelectric ceramic material with high switching field, copper inner electrode for the multilayer construction, firing in reducing atmosphere, applying a sputter method for the outer connecting electrode combined with silver sintering of a flexible termination or of a pressfit connector. The third goal is to show how the new technologies are applied such that the cost forecast in production scale is giving a good economic perspective for future use in power electronic systems. Finally, specific applications in power electronics are selected and described, where the benefits resulting from the new technologies are made evident.

The main components of power electronic systems are the switching semiconductors, the control electronics, the inductive and capacitive passive components, sensors, chassis, cooling, control electronics, and connector elements. All these need to be robust, highly efficient, and have a good relation of cost to performance. For optimum and low system size, low losses, and for lowest possible cost, a careful balancing of the semiconductor switching speed, frequency of switching, current density, and ripple and turn-off overshoot voltage is necessary. The recent trend of the development of switching semiconductors is towards higher switching frequencies, steeper switching slopes, higher junction temperatures, higher current density, and less size while keeping high robustness. The progresses in the semiconductor technology, there are interactions with the supporting passive components, in particular the DC-link capacitors.

In the present paper these shortcomings of the classical MLCC with respect to their application in power electronics will be dealt. At first, the relation between the MLCC specifications and the basic material properties for ferroelectric and for antiferroelectric ceramics are discussed. From the power electronics requirements, it is shown, that the ferroelectric MLCC cannot comply with the needs of high currents at high temperaures simultaneously. A change in development trend direction is needed, and it is recommended to develope and improve antiferroelectric dielectrics in the future, which are able to be processed with base metal electrodes. These materials can comply with the high current / high temperature needs, because of their material properties.

In marketplace, there is common understanding that MLCC specification is such that the capacitance is measured at 25°C, 10kHz, Vrms = 1 Volt, no bias voltage applied and the same holds for the dissipation factor, and comparisions are made on the basis of this condition. However, in power electronics, e.g. when using the capacitor as a DC - link, or a snubber there is the need for specification at high link - voltage (e.g. 400 Volt DC- link voltage for 650 Volt semiconductors), at higher ripple voltages, and at much higher frequencies according the switching features of the semiconductors.

Fig1

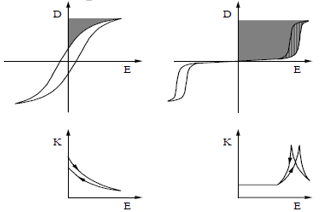

It is important to realize, that all ferroelectrics show a decrease of dielectric constant with bias voltage, with no exception. The high K values noted above always go down to 400 ~ 500, when the voltage has induced full ferroelectric polarization. The corresponding antiferroelectric behaviour of the electronic polarisation, is schematically depicted in Fig.1 (b), in contrast to the ferroelectric case the dielectric constant i slow for low field, and increases then. Fig. 2 shows examples. The field dependence of K is shown for an antiferroelectric capacitor (with Cu inner electrodes, commercially available as « CeraLink » from EPCOS), in comparision with a commercial BaTiO3 - based MLCC. For the latter it is important to emphasize, that the zero field value of K does not matter, the high field value of K will go down to 400 to 500 anyway. A further note is, that in (BaTiO3) - based MLCCs designed for power electronics use the field strength at reated voltage reaches values >20 Volt/µm, otherwise the capacitance density will go down considerably.

上一篇: 连续离子注入形成的化合物半导体纳米晶体

下一篇: DDMAF化学辅助抛光单晶硅