In this paper, a novel wet etched silicon interposer for optical interconnection applications has been proposed and fabricated. The interposer concept is conceived to include, via flip chip bonding, both CMOS ICs and optoelectronic dies to allow close proximity of electronics (drivers, TIAs) to photonics (VCSELs, PDs). The fabrication steps are developed to realize silicon recessed areas, to fit the semi-conductor circuitry, and openings to fit mechanical optical interface (MOI). Two steps of silicon anisotropic wet etch are performed to define these areas. The metal traces for electrical connection are designed to match the impedance for signal transmission and are lithographically defined. The obtained silicon interposer is shown and the process challenges discussed.

In the past few decades, the performance of data centres (DC) and High-performance computing (HPC) has been growing with an exponential rate. To sustain this growth rate, it is projected that existing electrical interconnects in standard 19” width rack equipment connecting ASIC and pluggable transceivers on the front panel will be replaced by mid-board-optics (MBO) due to the front panel bandwidth density limits . The footprint and the cost of the key modules (transmitter and receiver) are the main limitations, mostly due to the complex packaging. At present, the vertical-cavity surfaceemitting lasers (VCSELs) and surface normal photodetectors (PDs) arrays are the most promising photonic technology to realize transceivers. During the fabrication, the components are packaged on printed circuit boards (PCB), where dense integration is complicated and costly to assemble and fabricate. Besides, point-to-point wire bonding is employed to make the connections between the CMOS IC and optoelectronic dies, which increases the cost and suffers from limited RF performance .

In this paper, we take advantages of silicon wafer scale process, and fabricate a novel silicon interposer by wet etching and double side-etching. The patterned silicon interposer is then gold plated to link the dense interconnections between the FR-4 PCB and the silicon ICs. Also, funnel-shaped TSV are realized to couple the laser light from a VCSEL to the mechanical optical interface (MOI) and Multiple-Fiber Push-On/Pull-off (MTP/MPO) connector.

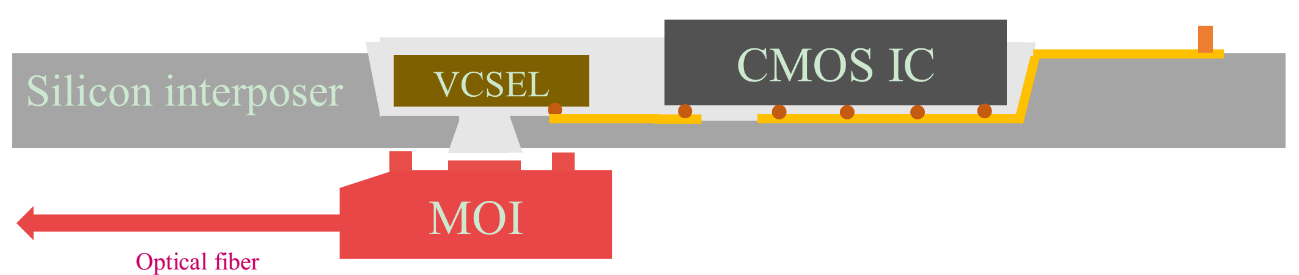

We propose a scheme to assemble the components scalable to wafer level packaging/assembly, which can provide the high performance and cheap transmitter module. As shown in Fig.1, the silicon interposer has been designed to assemble the CMOS driver, VCSEL and MOI. The chips, VCSELs and driver, are embedded in the silicon interposer. Lithographically defined metal traces, impedance matched for high speed transmission, are defined at the front-side of the interposer. At the backside of the same interposer the MOI are placed after opening the squared TSV to get light from the 12 VCSEL channel.

Fig1

The 2nd lithography is carried out on the already etched structure, after sputtering the seed layer for plating. The thick positive chemically amplified photoresist AZ® 40XT is employed for electro-plating. As shown in the Fig. 4(a), the photoresist is smoothly continuous after exposure and development of the photoresist: the light traces are the opening in the photoresist. A one micron thick layer of gold is then plated. Fig. 4b & c, shows the fan-out differential traces and short ground signal ground (GSG) traces between CMOS and VCSEL array after removing the seed layer.

上一篇: 硅通孔的湿法工艺技术

下一篇: 氮化镓压电半导体陶瓷中的电流相关性断裂