Various types of glass substrates have been compared withrespect to their suitability as a low-loss substrate in wafer-level chip-scale packaging for RF applications. Processabilityhas been evaluated by fabrication of shallow and decprecesses using wet etching in HF (/HPO) solutions.Electrical characteristics (dielectric constant and attenuation)have been extracted from measurements on coplanar waveguides (CPWs) up to 10 GHz.

Results show that Coring Pyrex #7740 glass providesoptical quality of wet-etched deep rccesses, but exhibit about2 times higher electrical attenuation than Hoya SD-2. Pyrex#7740 and SD-2 are thermally matched to silicon and due tosome alkali content, they are suitable for anodic bonding. Therelatively high content of AlO; (-20%) in SD-2 is favorablefor its electrical properties, but makes wet etching of deeprecesses more difficult. The non-alkaline AF45,with CTEalmost 2 times of Si (CTEAF4s=4.5x10* K'), is suitable foradhesive bonding and is difficult to pattern using wet etching.Its electrical attenuation is close to that of SD-2. Themeasured dielectric constants (at 6 GHz) for SD-2, Pyrex#7740 and AF45 are 4.7, 5.9 and 6.1, respectively.

Glass is a popular construction material for microfluidicand sensor devices duc to its ineriness, stability andtransparency. Because of its low dielectric losses, glass is alsoattractive as a substrate for RF applications, Silicon waferswith RF devices fabricated using IC technology are bonded toplanar glass wafers whereupon silicon is being partlyremoved [1]. This, so called substrate transfer technologyallows to gain all advantages of low losses in glass at RFfrequencies, still utilizing conventional silicon technology fordevice fabrication. Bonding of 3D-structured glass substrateto a core RF silicon wafer with wafer-to-wafer electricalinterconnects may enable realization of a variety of novel RFstructures (high-Q passives, transmission lines, suspendedground planes,integrated antennas, on-chipshielding, etc.)and represents a truly added value to the concept of wafer-level chip-scale packaging. Shallow and deep recesses in glasswafers are rcquired for certain RF applications. Sufficientscparation between the mmetal structures on the glass and thesurface of lossy silicon substrate is required to avoid Eddycurrents. Moreover, recesses in glass can also be used forprotection of RF MEMS structures [2]. The main problem infabrication of deep recesses (depth 50-150 um) in glasssubstrates is the complex composition of various glass typesresulting in rough surfaces and non-uniformity in etchingprofiles.

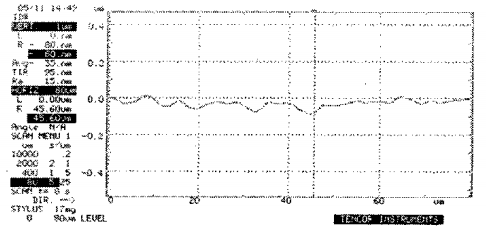

Fig1

Several methods exist to obtain the electrical properties ofa material. From all of them, we have chosen one that can beused to characterize thin planar materials without any specialsample requirements. The electrical properties are obtainedfrom the S-parameters measurements of a planar transmissionline test-cell. The coplanar waveguide (CPW) was usedbecause of the possibility to define a planar shape that canpropagate a dominant mode (quasi-TEM). In the case ofdominant mode, the coplanar characteristic impedance isquasiconstant in a broad frequency range and for a largevariety of substrates and a cell structure obeying h > S + 2W. This cell has also the benefit of avoiding the use of vias toground.

In this work, wet etching and electrical properties of threedifferent glass substrate types, namely Pyrex #7740, Hoya SD-2 and Schott AF45, were investigated. They have beencomparedwith respect to their suitability as low-losssubstrates in wafer-level chip-scale packaging for RFapplications. Processability has been evaluated by fabricationof shallow and deep recesses using wet etching in HF(HPO4)solutions. Electricalcharacteristics (dielectricconstant andattenuation)have been extracted frommeasurements on coplanarguides (CPWs) up towave10 GHz. The results achieved are summarized in Table 5.

上一篇: 单晶硅纳米结构的金属辅助化学蚀刻技术

下一篇: 用于控制合成金属纳米晶体的氧化蚀刻