Laser removal of small 1 mm sized copper, gold and tungsten particles from silicon wafer surfaces was carried out using ultraviolet radiation at 266 nm generated by Nd:YAG harmonic generation. Successful removal of both copper and gold particles from the surface was achieved whereas tungsten particles proved to be diffificult to remove. The cleaning effificiency was increased with an increase of laser flfluence. The optimum processing window for safe cleaning of the surface without any substrate damage was determined by measuring the damage threshold laser flfluence on the silicon substrate and the required flfluence for complete removal of the particles. The different cleaning effificiencies with particle type are discussed by considering the adhesion force of the particle on the surface and the laser-induced cleaning force for the three different particles.

There proves to be a continual need to develop effective techniques for the removal of small particles in the semiconductor industry. As semiconductor and microelectronic devices are becoming increasingly smaller, surface contamination of these devices is becoming an increasing problem for manufacturers due to the adverse effects that micron and submicron particles have on the device performance. In some cases they act as a potential source of circuit failure, threatening production yield. For example, particles in the size of about 0.1 mm to several microns possibly deposited on surfaces from air, liquids and humans in the processing environment are considered to have killer defects for the generation of dynamic random access memory (DRAM) and microprocessors. The use of wetchemical techniques for particle removal poses environmental problems due to the vast quantities of water that are used and also the discard of the chemicals themselves. Moreover, the chemicals could prove hazardous to human health. Other conventional cleaning techniques such as wiping and scrubbing are often limited due to possible substrate damage caused by the mechanical action on the surface.

Recently, a non-contact dry laser cleaning technique, using a short-pulse (in the order of ns) laser irradiation on the surface, has been demonstrated as a potential solution for the removal of particles from critical surfaces. This novel technique has the capacity to clean submicron particulates and has unique advantages over conventional methods. This approach utilises the versatile, controllable, selective and environmentally friendly nature of the laser system to optimum effect. It is seen to be non-obtrusive in the production process since no vacuum or special protective atmospheres are required and the beam of the laser can be highly localised allowing specifific areas of contamination to be targeted. These unique characteristics of laser cleaning have been demonstrating an effective removal of contaminants from various surfaces in industry.

In this paper the removal of small copper, gold and tungsten particles with a diameter of 1 mm from silicon wafers has been carried out using ultraviolet radiation of 266 nm. It is known that metal particles absorb more laser energy at shorter wavelengths and the thermal damage threshold flfluence for silicon increases at shorter wavelengths. When both of the above are taken into consideration shorter wavelength lasers (UV lasers) are more effective for the removal of metallic particles from silicon wafers without inducing substrate damage. Thus the ultraviolet laser, with a wavelength of 266 nm, produced by frequency harmonic generation of the fundamental Nd:YAG radiation of 1064 nm was used in this work. Quantitative analysis was carried out in order to determine the flfluence values that induced substrate damage to the silicon wafer at this wavelength and the threshold flfluence values above which surface cleaning was observed were also found by surface analysis. The cleaning effificiency with laser flfluence was measured for the different particles and compared with each other. In addition theoretical analysis was carried out for the different particle/substrate combinations in order to understand the effect of particle type in the laser cleaning process.

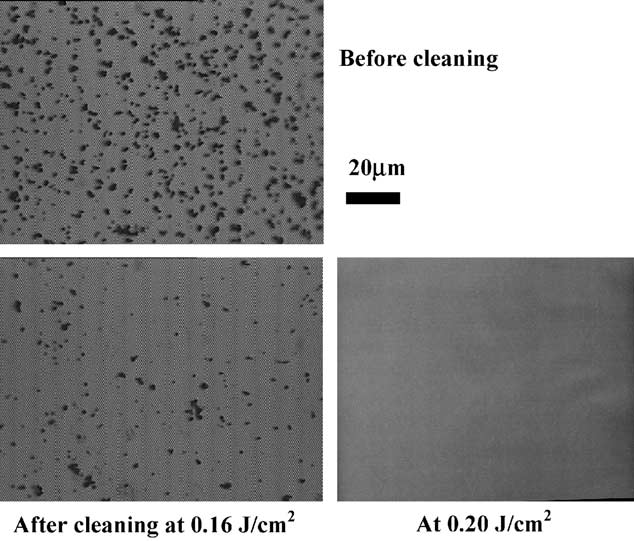

Fig1

Fig. 1 shows the silicon surfaces before and after laser removal of copper particles from the silicon wafer surface. Ten laser pulses with flfluences of 0.16 and 0.20 J/cm2 were used at 266 nm. It can clearly be seen that over half the particles have been removed at a flfluence of 0.16 J/cm2 and all particles appear to be removed from the surface at a slightly higher flfluence of 0.20 J/cm2 . These flfluence values are well below that of the damage threshold at 266 nm and no possible damage could have incurred on the surface during cleaning. This implies that effective energy coupling between the laser and the copper particles has been induced at 266 nm.

Fig. 2 shows the silicon surfaces before and after laser removal of gold particles from silicon wafer at 266 nm. Ten laser pulses with flfluences of 0.05 and 0.08 J/cm2 were used. It can be seen that a large number of particles were removed at the lower flfluence of 0.05 J/cm2 while a complete removal of all gold particles was achieved at the higher flfluence of 0.08 J/cm2 , which is far below the damage threshold flfluence. It was seen that successful removal of gold particles could also be achieved at 266 nm wavelength without introducing damage to the wafer. In addition a much smaller flfluence was required for complete removal of gold than that for copper. This implies that there is more effective energy coupling between the laser and the gold particles than the copper particles.

上一篇: 紫外和深紫外二阶非线性光学晶体的最新进展

下一篇: 薄硅衬板上半导体芯片热力学性能研究