We have characterized the SiO2/SiC system in terms of bonds and composition by angleresolved X-ray photoelectron spectroscopy for two different oxidation processes: a standard oxidation, and a process which includes a re-oxidation step. Although the oxide is quite stoichiometric (Si4+ oxidation states) far away from the interface, the analyses revealed at the SiO2/SiC boundary a complex transition layer containing “mixed” (Si-O-C) compounds. After the so-called re-oxidation procedure, we have observed a significant decrease (30%) of the Si bonds related to these (Si-O-C) species. From these results, the improvement of the electrical properties of SiO2/SiC interface during the re-oxidation can now be clearly related to the reduction of the carbon products.

Silicon Carbide (SiC) is an advanced IV-IV compound wide band gap semiconductor. This material is especially suitable for high-power, high-temperature, and high-frequency devices because of its superior properties such as wide band gap, high breakdown field, high saturation electron drift velocity, and high thermal conductivity. In particular, one of the main advantages of SiC over others semiconductor materials is that it can be thermally oxidized to form a SiO2 layer suitable for MOS and MOSFETs related devices.

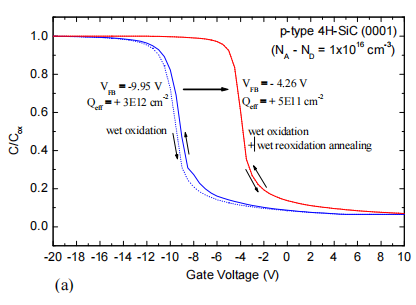

Nevertheless, the conventional oxidation process results in formation of a SiO2/SiC interface with poor electrical properties due to high effective fixed charge density (Qeff) and high interface state density (Dit). These interface states induce a reduced channel mobility through carrier trapping and Coulomb scattering. Whereas the carrier mobility in Si near SiO2/Si interface is smaller by a factor of two to bulk, the mobility near SiO2/SiC interface is one to two orders of magnitude smaller than the bulk depending on the polytype. The degradation is worse for the 4H polytype of SiC which is preferred over 6H for device applications because of its larger band gap and more isotropic mobilities.

Several studies have suggested that the high interface states density observed in SiO2/SiC arises from carbon clusters and silicon oxycarbide . More recently, wet re-oxidation annealing at low temperature was reported to reduce the interface state density of p-type MOS capacitors. Meanwhile, to our knowledge, the effect of this annealing on the interface chemical environment has not been experimentally identified. In this paper, we will review angle-resolved x-ray photoelectron spectroscopy analyses (AR-XPS) on SiO2/4H-SiC (0001) interface.

Fig1

The same analysis procedure was applied on sample (b) (HF etch to keep 7 nm of oxide – ARXPS analyses). The Si 2p core level spectrum (not shown) of this sample (b) is similar to the one of Fig. 3, indicating that there is still mixed (Si-O-C) oxidation products at SiO2/SiC interface. The comparison of Si II atomic concentration before and after re-oxidation shows for both angles a decrease of more than 30% of the Si bonds related to (Si-O-C) contribution after the re-oxidation. This result highlights the fact that the re-oxidation process reduces significantly the oxicarbide species in the transition layer region. This experimental observation gives weight to the assumption according to which the new O atoms supplied during the re-oxidation process interact with the C clusters and exodiffusion of C is done by probably releasing both CO and CO2 molecules.

Using AR-XPS, we have investigated the SiO2/SiC interface before and after a wet re-oxidation procedure. Our results indicate that the oxidation of SiC surface results in a complex interface involving (Si-O-C) species. The width of the transition layer has been estimated to a minimum of 3.7 nm. A benefit effect of the re-oxidation procedure has then been identified on the SiO2/SiC interface. The low temperature annealing clearly reduces the oxicarbide species by more than 30%. This point is important as it highlights that there exists a strong relationship between the concentration of “mixed” oxide at the interface and the electrical quality of the SiO2/SiC system.

上一篇: 纳米电子学的硅表面和界面问题