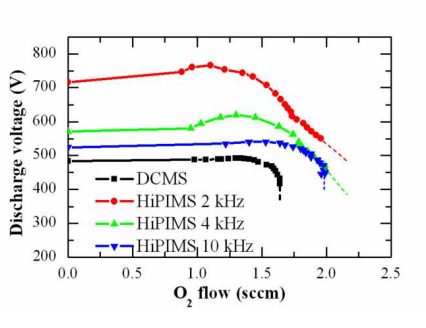

In the further development of reactive sputter deposition, strategies which allow for stabilization of the transition zone between the metallic and compound modes, elimination of the process hysteresis, and increase of the deposition rate, are of particular interest. In this study, the hysteresis behavior and the characteristics of the transition zone during reactive high power impulse magnetron sputtering (HiPIMS) of Al and Ce targets in an Ar-O2 atmosphere as a function of the pulsing frequency and the pumping speed are investigated.Comparison with reactive direct current magnetron sputtering (DCMS) reveals that HiPIMS allows for suppression/elimination of the hysteresis and a smoother transition from the metallic to the compound sputtering mode. For the experimental conditions employed in the present study, optimum behavior with respect to the hysteresis width is obtained at frequency values between 2 and 4 kHz, while HiPIMS processes with values below or above this range resemble the DCMS behavior. Al-O films are deposited using both HiPIMS and DCMS. Analysis of the film properties shows that elimination/suppression of the hysteresis in HiPIMS facilitates the growth of stoichiometric and transparent Al2O3 at relatively high deposition rates over a wider range of experimental conditions as compared to DCMS.

Reactive magnetron sputtering is a physical vapor deposition (PVD) technique which is widely employed for the growth of compound films allowing for good film uniformity, reliable control over the film properties, deposition on large area substrates, and cost efficiency . Typical feature in reactive magnetron sputtering processes is that compound formation does not only take place on the substrate but also on the target surface (referred to as target poisoning). Deposition from a fully poisoned target (referred to as the compound sputtering mode) allows for growth of stoichiometric compound films, i.e. films with sufficient incorporation of the reactive gas atoms . At these conditions deposition rates significantly lower than those obtained from an elemental (e.g. metallic) target are commonly observed, since the sputtering efficiency of the compound material is typically lower than the sputtering efficiency of the corresponding metal . Growth of stoichiometric compound films with relatively high rates can be facilitated in the transition regime between the metallic and the compound mode . However, the relationship between reactive gas flow and process parameters is complex leading to an unstable transition zone and a hysteresis in the process parameters, e.g. decrease and increase in the deposition rate does not occur at the same value of the reactive gas flow. Therefore, operation in the transition zone using only the reactive gas mass flow as the control parameter is in most cases impossible The latter is particularly pronounced during reactive sputtering of metal oxides. It has been shown that stabilization of the transition zone or elimination of the hysteresis can be achieved by feedback control systems , increase of the pumping speed , reduction of the target area , and for some metal oxide systems by the addition of nitrogen into the sputtering atmosphere.

The goal of the present study is to explore the feasibility of HiPIMS to stabilize transition zone and eliminate the hysteresis during reactive deposition over a wide range of experimental parameters. In addition, we seek to contribute to the understanding of the fundamental mechanisms that determine the process characteristics in reactive HiPIMS processes. To this purpose we study the process characteristics during reactive HiPIMS and DCMS of Al and Ce in an Ar-O2 ambient using a variety of experimental parameters with respect the pulsing frequency and the pumping speed. The results obtained are discussed in light of the mechanisms suggested in the literature. Finally Al-O films where grown and their optical properties was compared for the two deposition techniques.

Fig1

A typical feature of the HiPIMS process is the relatively high peak target current which results in depletion (rarefaction) of neutral species in the vicinity of the target . The rarefaction affects not only the Ar but also the reactive gas species . It has been suggested in the literature that the latter has as a consequence a lower effective flux of reactive species towards the target which in turn results in the elimination/suppressions of the hysteresis and the stabilization of the transition zone in reactive HiPIMS processes. The decrease of the pulsing frequency for a constant average power (or current) leads to larger peak target currents and thus more pronounced gas rarefaction. At the same time smaller frequencies imply longer time between the pulses which in turn means more time available for the gas to be replenished in the target’s vicinity. These mechanisms may explain the fact that an optimum behavior with respect to the hysteresis width is obtained at intermediate pulsing frequencies (Figs. 3 and 4). Another mechanism that can be used to explain the behavior observed in Figs. 3 and 4 is based on the limited target oxidation between the pulses caused by the reduced reactivity of O2 under the absence of plasma . Decrease of the frequency enhances the tendency for limited target oxidation during the pulse off-time since the time between pulses becomes longer. This is counteracted by the increase of the peak 11 target current which in turn leads to a larger plasma density and eventually a larger density of activated (i.e. excited) reactive gas species.

In the present study the hysteresis behavior and the characteristics of the transition zone during reactive HiPIMS of Al and Ce targets in an Ar-O2 atmosphere have been investigated over a large range of experimental parameters with respect to the pulsing frequency and the pumping speed. Our results revealed that HiPIMS allows for suppression/elimination of the hysteresis observed in DCMS and a smoother transition from the metallic to the compound sputtering mode. In the used deposition system, optimum behavior with respect to the hysteresis width has been obtained at frequency values between 2 and 4 kHz, while HiPIMS processes with values below or above this range resemble the DCMS behavior. The relationship between the pulsing frequency and the hysteresis behavior has been tentatively explained on the basis of the gas rarefaction and the limited target oxidation between the power pulses. The elimination/suppression of the hysteresis in HiPIMS has facilitated the growth of stoichiometric and transparent Al2O3 at relatively high deposition rates over a wider range of experimental conditions as compared to DCMS.

上一篇: 超出电信波长范围的硅基光子的集成

下一篇: 用激光产生的兰姆波检测单晶硅晶片的裂纹