The cost-effectiveness of market-dominating silicon wafer solar cells plays a key role in determining the competiveness of solar energy with other exhaustible energy sources. Reducing the silicon wafer thickness at a minimized efficiency loss represents a mainstream trend in increasing the cost-effectiveness of wafer-based solar cells. In this paper we demonstrate that, using the advanced light trapping strategy with a properly designed nanoparticle architecture, the wafer thickness can be dramatically reduced to only around 1/10 of the current thickness (180 mm) without any solar cell efficiency loss at 18.2%. Nanoparticle integrated ultra-thin solar cells with only 3% of the current wafer thickness can potentially achieve 15.3% efficiency combining the absorption enhancement with the benefit of thinner wafer induced open circuit voltage increase. This represents a 97% material saving with only 15% relative efficiency loss. These results demonstrate the feasibility and prospect of achieving high-efficiency ultra-thin silicon wafer cells with plasmonic light trapping.

Being the dominant products on the photovoltaic market, crystalline Si wafer solar cells have been the intensive research focus for years1 . Increasing the energy conversion efficiency and reducing the cost have been the two major driving forces for the solar industry and academic research to make solar electricity more competitive with the conventional fossil fuel. An effective way of cost reduction is to make the wafer thinner since the wafer cost accounts for approximate 50% of the solar cell cost2 . In the past few decades, the wafer thickness has been reduced from 400 mm to the current 180 mm and the trend of reduction is continuing2 . Apart from the cost saving consideration, thinner wafer can potentially lead to a higher open circuit voltage, Voc, due to the lower bulk recombination and more efficient electron-hole pair extraction.

However, the wafer thickness reduction poses a great challenge for efficiency maintenance due to the significant light absorption decline at the longer wavelengths, especially when the wafer thickness is reduced to below 50 mm8 . The longer wavelength light has a lower absorption coefficient, requiring a larger travelling distance in Si to be completely absorbed. To fully appreciate the benefits of wafer-thickness-reduction-induced cost savings and higher electrical performance, advanced light trapping technology targeting the longer wavelength region of the solar spectrum is pressingly required to be developed.

Metallic nanoparticles, which support localized surface plasmons, have been demonstrated to be able to provide advanced light trapping mechanisms to significantly enhance the light absorption in solar cells by the scattering and near-field effects. So far, most of the plasmonic solar cell research has been focused on the thin film technology. Only limited work has been conducted on Si wafer solar cells using Ag or Al nanoparticles due to the fact that thick silicon wafer cells absorbs almost 90% of the sun light higher than the bandgap. There is limited room to further increase. However, as the wafer thickness reduces, the nanoparticles are expected to play an increasingly important role.

Fig1

In this manuscript, through theoretically exploring the maximum potential of the light absorption that can be achieved by metallic nanoparticle arrays within the Si wafer solar cells, we find that plasmonics light trapping plays a pivotal role in the efficiency enhancement of ultra-thin wafer cells of thickness down to 1 mm. We further identify that the critical design parameters of the ordered nanoparticle array for maximum light absorption enhancement are wafer-thickness dependent. Furthermore, we experimentally verify the large absorption enhancement within ultra-thin Si wafers by plasmonic nanoparticles. The insights in this article open up a new perspective and guidance for achieving high efficiency wafer solar cells at the ultra-thin Si thickness.

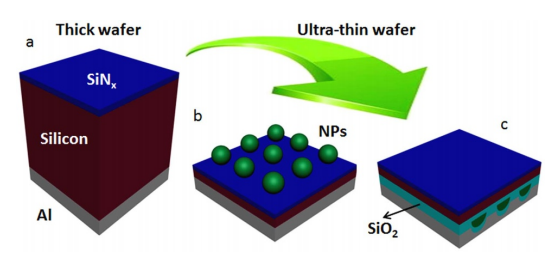

Fig. 1a shows the thick 180 mm solar cell with a standard configuration (cell without nanoparticles) used throughout this study, consisting of a 75 nm SiNx antireflection coating (ARC) layer on the surface of a Si wafer. 75 nm is the optimized thickness for SiNx as an ARC layer. An optically thick Al back reflector is located underneath the wafer. Figs. 1b and 1c identify, respectively, the ultra-thin solar cells with the light trapping nanoparticles located on the front surface of the SiNx ARC and embedded in a SiO2 dielectric layer positioned between the Si wafer and the Al back reflector. The front nanoparticles can both reduce the light reflection at the front surface due to the optical impedance matching and the light path length increase particularly for the longer wavelengths as a result of the scattering induced angular redistribution of the incident light. The rear nanoparticles also can enhance the light path lengths by scattering. In addition, the scattered light with angles larger than the critical angle of the front interfaces can be trapped inside the Si due to total internal reflection. To avoid the transmittance reduction introduced by the surface plasmon polariton at the longer wavelengths28, spherical nanoparticles are used on the front surface to minimize the contact area between the metallic nanoparticles and the substrate, while hemispherical nanoparticles are used on the rear side of the cells due to a better coupling of the scattered light into the Si layer21. The SiO2 spacing layer between the Si and Ag nanoparticles is 20 nm, which is a balance between light incoupling and rear surface passivation21. Another 100 nm SiO2 layer is designed under the nanoparticles, for electrical isolation.

Two metals, Al and Ag, were selected as the front located nanoparticle materials for light trapping while Ag nanoparticles for rear light trapping. Al nanoparticles, with their surface plasmon resonances located in the UV region below the usable solar spectrum edge at 300 nm, have been demonstrated to be able to avoid the light incoupling loss and introduce an extra enhancement in the shorter wavelength range24,25. Ag nanoparticles, however, have larger scattering strength and less particle absorption than the Al nanoparticles at the longer wavelengths. Therefore it is expected that the optimized material for the front located nanoparticles might switch from Al to Ag when the wafer thickness reduces to a certain extent where the light trapping for the longer wavelengths is predominant. While Ag is the best material for the rear side since the only consideration is the longer wavelength light trapping.