Large-area wafer bonding of different III–V compound semiconductors in an ultrahigh vacuum background is demonstrated. The bonding procedure, the microstructure, and the mechanical strength of the bonded GaAs/InP and GaAs/GaP interfaces were studied. The cleaning procedure and the bonding were separated in order to avoid undesired artifacts and thermal stress at the interface. First, thermally generated atomic hydrogen was employed to clean the surfaces. Then, the wafers were brought into contact below 150 °C. At contact, the interface formed spontaneously over the whole wafer area without application of a mechanical load. Transmission electron microscopy showed the formation of atomically direct interfaces and misfifit dislocation networks. The fracture surface energy was measured as being comparable to that of respective bulk materials. Heat treatments of the bonded GaAs/InP samples led to relaxation of the interfaces but also to the formation of nanoscopic voids in the interface plane and volume dislocations.

Direct wafer bonding (DWB) of III–V semiconductors has become increasingly important as a key technique for fabricating optoelectronic devices. It enables interface formation between different materials, which, due to large lattice mismatch (see Table I), cannot be epitaxially grown on one another without the formation of a high density of threading dislocations. The applied fifields involve manufacturing of high brightness light emitting diodes (LED), vertical cavity surface emitting lasers (VCSELs) , distributed feedback lasers,10 optic coupling,11 second harmonic generators ( SHGs) , waveguide arrangements, stacked cascade solar cells, and fifield effect transistors. Thus, the necessity of understanding and controlling wafer bonding of compound semiconductors will further increase in the near future.

In addition, the gaseous products from the reduction of oxides, decomposition of contaminants, and outgassing are enclosed at the interface, leading to the formation of different size bubbles or voids. In order to avoid void formation, one of the surfaces to be bonded is often patterned with a grid of channels a few to 100 μm in width and a pitch of a few 100 μm.

Recently, uniform direct wafer bonding of whole GaAs wafers was achieved by two methods. In both cases, the wafer surfaces are cleaned in situ, and then contacted, or bonded, without any mechanical load. Accordingly, this enables one to avoid enclosing undesirable released surface contamination during heating and to conduct bonding at low temperatures.

Fig1

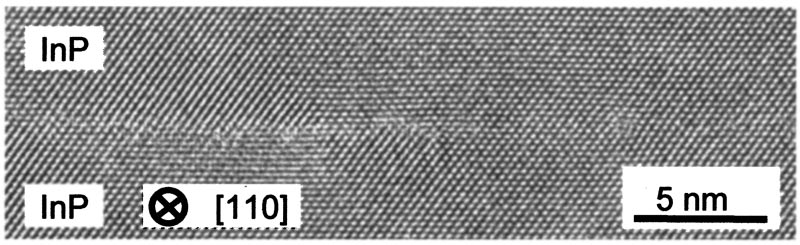

Following the cleaning and some cooling, the wafers were brought into contact by rods from both sides. No intentional mechanical load was applied, only a gentle force just large enough for the wafers to come into contact (Fig. 1). For all the bonding experiments, the (001) surfaces were bonded. The (110) directions of both wafers were aligned parallel using the orientation flats of the wafers. Since almost always there is inaccuracy in the crystallographic orientation of the flflats, rotational misorientation between the two wafer crystals of less than 1° (for details, see Ref. 18) is often present.

Thermally generated atomic hydrogen was employed to clean various III–V compound semiconductor wafers in an UHV background. Using this method, it was demonstrated that different III–V wafers such as GaAs/InP and GaAs/GaP can be bonded at temperatures below 150 °C without application of mechanical loads, and form wafer-size bond areas. TEM observations showed that atomically abrupt interfaces result in misfit dislocation networks even at the interfaces that formed below 150 °C. The interface structure and adhesion, comparable to the cohesion of bulk materials, clearly demonstrate that low temperature covalent bonding of different III–V compound semiconductors is possible. The following merits underscore the high manufacturability of this bonding technique. (1) No pretreatment using chemicals is necessary. (2)Whole wafer areas can be bonded without application of a mechanical load. (3) Extension of the bonding procedure to wafer dimensions of any size appears to be possible. (4)Bonding at low temperatures may enable integration of many other different materials combinations. The electronic properties of the interfaces formed are now under investigation.