Increasing reliance on carbon-based fossil fuel is likely to cause irreversible damage to global environment. Crystalline silicon (Si) based on pollution free photovoltaic (PV) electricity generation technology is expected to play a dominant role in this electricity generation transition from carbon to silicon. Since Si wafer represents almost 50% of the PV conversion cost, thinner wafers are highly effective at reducing the production cost. Therefore, there is an urgent need to develop alternative device configurations and processing methods for thinner Si wafer. Si wafer has to go through cleaning process, thinning process, textured process and partially transparent technique. In this work optical transmission through Si is investigated as a function of wafer thickness. For this improved performance, surface morphology, optical properties and the optical transmission near band gap is measured with custom-designed rear infra-red (IR) transmission measurement system. Si wafer with the textured surface have more light absorption than the as-cut and planar Si wafer.

Peningkatan kebergantungan terhadap penggunaan bahan bakar berasaskan sumber karbon mengakibatkan pencemaran alam sekitar. Fotovolta (PV) sifar pencemaran berasaskan silikon kristal merupakan teknologi tenaga elektrik generasi terkini dijangkakan menjadi sumber yang mendominasi perubahan sumber bahan api berasaskan karbon kepada silikon. Tambahan pula, kepingan silikon meliputi 50% kos keseluruhan pembuatan PV, pengurangan kos yang efektif didapati melalui penipisan kepingan.. Oleh itu, kaedah alternatif kepada pembaharuan bagi konfigurasi sistem penipisan silikon harus di cadangan. Kepingan silikon harus melalui proses pembersihan, proses penipisan, proses tekstur dan teknik separa telus. Dalam kajian hubungan di antara ketebalan kepingan silicon dan maklumat optik diteliti. Bagi meningkatkan prestasi, morfologi permukaan, sifat optik, dan penghantaran optik menghampiri jurang jalur diukur dengan menggunakan sistem pengukuran penghantaran gelombang IR.

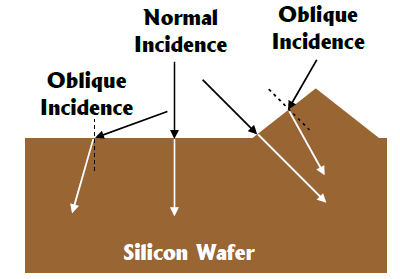

Silicon wafer-based photovoltaic module production has been growing over 30% since the last decade. Generally, the cost of Si accounts for almost 50% of a photovoltaic panel. Historically, a pathway to reduce cost has been realized by economic use of Si in the form of thinner substrates; current Si wafer is in 150 – 200 𝜇m thickness. Si PV technology is almost exclusive based on mono-facial solar cells in which light is incident from the front surface with the back surface completely metallized. The bifacial solar cell is an emerging solar cell configuration in which electrical grid patterns are identical on both front and back surfaces. This device configuration has the potential to generate more power by capturing scattered light from the rear surface than the mono-facial solae cell. The challenging problems in bifacial solar cell is to ensure that the photo-generated electronhole (ē-h) pairs absorbed near the back surface are collected by the front surface emitter prior to recombination. This experiment can be done by using appropriate surface texturing methods, light trapping can be enhanced and absorption in the rear-infrared (NIR). The optical properties of a broad range of different bifacial configurations with varying surface morphologies and rear side reflectors have been extensively investigated in the literature. Although wafer thickness reduction translates into smaller recombination losses and large open circuit voltages; absorption is reduced as well.

Fig1

The estimated time would be 1 hour and 45 minutes at the temperature of 70 – 80 ℃. Next, the IR transmission data will be measured. Figure 2(b) shows the etching process by using HF:HNO3 with a ratio of 1:10. Then, Si wafertextured were dipped in a solution of HF:HNO3 with ratio of 1:10 for 1 hour and 45 minutes. Then, the wafers were rinsed and dried with nitrogen gas. The IR transmission data is recorded from (600 – 1200) nm wavelength with sub-wavelength 25 nm. Figure 2(c) shows a process flow for paste Black Etching Surface (BES) paste process on silicon wafer with 200 μm thickness. Next, the oxidation process was applied to the Si wafers. The time estimated to produce the oxide layer approach 350 Ǻ is 1 hour and 30 minutes at the temperature 1100 ℃. The Si wafers size were then cut into 4 cm x 4 cm.The BES paste contains level of carbon black and n-methyl-2-pyrrolidone by EMD Chemicals Company is placed onto the mask and at the same time the Si wafer is placed under the mask. After that, the etched Si wafer is heated in the furnace at the temperature of 350 ℃ for 90 seconds. Next, Si wafer is soaked in 1% KOH for 1 minute at 40 ℃. After the BES paste is peeled out from the Si wafer, the Si wafer is placed into 10% KOH solution for 1 hour and 15 minutes at 70 ℃. Then, the Si wafer is rinsed using deionized (DI) water and dried with nitrogen gas.

A simple experimental setup based on optical configuration described in Figure 3 has been developed for characterization of near IR transmission as a function of wavelength. This system is designed to measure optical transmission system in near and far infrared (IR) range specifically for the wavelength. A computer controlled IR monochromator is used to vary wavelength in the desired range. Spectrally variable light from te monochromator is incident normally on the sample under measurement (SUM). The transmitted light from the sum is collected focusing lens onto an InGaAs photodetector. The output from photodetector is connected to a lock-in amplifier, which is connected to a computer. Intensity variation as a function of wavelength is measured with a LABVIEW based computer programme.