The present invention provides a surface grinding method for a semiconductor wafer, which performs surface grinding with respect to a semiconductor wafer sliced into a thin plate shape, wherein at least a cleaning process for removing a heavy metal is performed before carrying out Surface grind ing of the semiconductor wafer, and a Surface grinding pro cess is carried out after performing the cleaning process. As a result, there are provided the Surface grinding method and a manufacturing method for a semiconductor wafer, which can effectively reduce a contaminant, which has adhered to a Surface of the semiconductor wafer, e.g., a heavy metal Such as Cu.

In manufacture of a semiconductor device, when a heavy metal is present in a wafer itself or a fine particle contaminant is present on a wafer Surface, performance char acteristics of a device may be adversely affected in some cases. A semiconductor Substrate (a wafer) used for a semi conductor device is manufactured by mainly processing an ingot block grown by a pulling method (a Czochralski method, a CZ method) into a mirror-finished thin plate. This manufacturing process mainly includes a slicing process for slicing the ingot block into a wafer shape, a chamfering process for chamfering an outer peripheral portion of the sliced wafer, a flattening process for flattening the chamfered wafer by using, e.g., lapping or Surface grinding, an etching process for removing a mechanical damage of the flattened wafer, and a polishing process for polishing both sides or a single side of the etched wafer. Further, it also has a heat treatment process, an inspection process, various kinds of cleaning processes, and others.

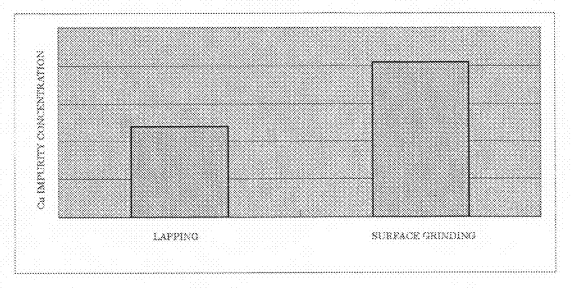

Performing the cleaning process for removing a heavy metal before carrying out Surface grinding of the semi conductor wafer in this manner enables carrying out Surface grinding after removing the heavy metal that has adhered to the wafer. Therefore, in a process having a great mechanical effect to generate heat like Surface grinding, a contaminant does not diffuse into the wafer, thus lowering a contamination level of the finally obtained wafer.

Fig1

Since a wafer surface is active in an etching process and an etchant to be used contains a large amount of a con taminant, the contaminant may highly possibly adhere to the wafer surface. When the wafer having the contaminant adhered thereto in the etching process is cleaned to remove the heavy metal and then Surface grinding is carried out, the contaminant does not diffuse into the wafer by Surface grind ing, thus consequently lowering the contamination level of the wafer.

Additionally, according to the present invention, there is provided a manufacturing method for a semiconduc tor wafer comprising at least a surface grinding process, wherein at least a cleaning process for removing a heavy metal is performed before carrying out Surface grinding of the semiconductor wafer, and a Surface grinding process is car ried out after performing the cleaning process.

Performing the cleaning process for removing the heavy metal before carrying out Surface grinding of the semi conductor wafer in this manner enables carrying out Surface grinding after removing the heavy metal that has adhered to the wafer. Therefore, the contaminant does not diffuse into the wafer by Surface grinding, thereby manufacturing the wafer having the low contamination level.