Cryoetching of silicon was introduced about 35years ago by a Japanese team.Anisotropicetching was obtained using a plasma of SF6interacting with a masked silicon wafer cooled toa very low temperature (typically -100°C) in orderto freeze chemical reactions on the trenchsidewalls. But, a new interpretation of cryogenicetching mechanisms was proposed by Batha et al.in 1995 involving a passivation mechanism withan important role of oxygen. Since this time,many in-situ experiments have been carried out toexplain the formation of the SiOxFy passivationlayer, which preferentially forms at lowtemperature. In particular, the role of SiF4molecules, which are the main by-products ofsilicon etching in fluorine based plasma washighlighted.In this paper, we will describe thein-situ experiments using mass spectrometry,ellipsometry and XPS on ICP reactors in SF6/O2and SiF4/O2 plasmas, that have been conducted tobetter understand the formation and thecharacteristics of the passivation layer.

The cryoetching experiments were performed in 3different Inductively Coupled Plasma (ICP)reactors: two industrial reactors installed atGREMI laboratory and one home made ICPreactor dedicated to in-situ XPS analyses installedat IMN laboratory. The reactors can operate indifferent gases such as Ar, SF6, O2, C4F8 and SiF4.Industrial reactors are configured for 150 mmdiameter wafers that are introduced from a loadlock. The substrate is cooled with liquid nitrogenand its temperature is regulated with a distributed thermal resistance to a set-point between +20 and-140°C. Helium gas is injected between the waferand the substrate holder to enhance the thermalconductivity. For high aspect ratio etchingexperiments, a mask of SiO2 was used. Theindustrial reactors are equipped with ellipsometry,mass spectrometry, Langmuir probe and OESdiagnostics for in-situ measurements. Quasi insitu XPS analysis was carried out on theOPTIMIST platform at IMN in Nantes where thehome made reactor was installed. 1 cm²samples are mounted on a rod and cooled at lowtemperature. They are first introduced in the ICPreactor for the plasma treatment and then directlytransferred to the XPS chamber by keeping thetemperature very low during the analysis.

Fig1

SiF4/O2 plasma can be used to create an SiOxFylayer that can be used to enhance the robustnessof the passivation. This is the principle of theSTiGer process. In figure 1, we show theSiOxFy layer growth when 30s long SiF4 plasmastep is alternated with 30 s O2 plasma step at20°C and at -100°C. The growth occurs duringthe SiF4 plasma. Without O2 plasma, we obtain agrowth as well, but the layer is less robust. TheSiFx growth is more efficient at low temperature.This result shows that the residence time of SiFxspecies, which is longer at low temperature, has akey role to meet the reaction conditions betweenO atoms and SiFx radicals to efficiently form thepassivation layer.

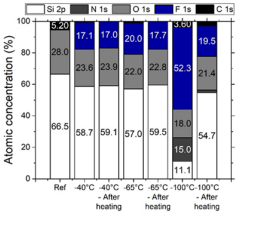

The very low temperature (-100°C) is necessary toform the passivation layer. This was shown by insitu XPS analysis. In figure 2, the compositionof the deposited layer that was obtained after 30 sof SiF4/O2 plasma on a silicon sample is reportedfor different temperatures. The “Ref” bar graphgives the surface composition before plasma.Then the surface composition after a process atlow temperature and after heating the sample areprovided. As observed, the most significantmodification before and after heating is obtainedat -100°C. It is clearly correlated to the SiFx molecule residence time that is increased bydecreasing the temperature.

The chemistry at the silicon surface in Si4/O2plasma is significantly modified at very lowtemperature. This property is attributed to thelonger residence time of SiFx radicals at thesurface at low temperature.

上一篇: SiC掺杂剂选择性光电化学蚀刻