The mobile device's limited thermal budget hardly allows the use of a high-performance application (AP) atits full speed. However, as artificial intelligence technologies has been rapidly applied for mobile devices,the demand like high-speed and large-capacity signal processing is continuously increasing. Therefore,controlling the heat generation of AP chip is becoming a key factor, and it is necessary to develop a ReDistribution Layer (RDL) based Fan-Out Package (FOPKG) structure that does not increase the thickness ofthe package while maximizing the die thickness for heat dissipation. The height of Cu post is getting higherfor the production of FOPKG that can apply thick die, and in this study, the world's thickest photoresistmaterial (>350um thickness) was developed for the production of Cu post (>300um thickness). The effect oflight transmittance of the photoresist and the effect of solubility depending on the molecular structure of themain polymer were studied for lithography process of thick photoresist. Based on the understanding of thisthick photoresist behavior, the optimal liquid type photoresist composition was developed. Throughlithography evaluation based on thick photoresist characteristics, deep-hole via implementation and Cuelectro-plating were performed to obtain a yield of Cpk 1.27 in the AP product design applied wafer.Depending on this in-depth understanding and experimentation on thick photoresist, it is possible to build anadvanced research foundation of increasing the photoresist thickness and finer Cu post pitch to secure heatdissipation characteristics and improve the degree of freedom of architecture.

In order to improve the performance of mobile devices suchas high-speed and large-capacity communication, heatgeneration of the AP chip must be controlled to a minimum,and the most efficient method is to increase the thickness ofSi (Die) which has lower thermal conductivity of Sicompared to other organic materials. The number ofcomponents for realizing high performance is increasing andmounting up to 5 sides is required, but the thickness of thedevice cannot be increased. Therefore, it is necessary todevelop a direction to increase the thickness of the AP Diewithout increasing the thickness of the AP package. Due tothe nature of the AP, DRAM (Memory) must be located asclose as possible for high-capacity and high-speed operation,and to implement this, a PoP (Package on Package) structureis required. That is, the solution for securing the diethickness is to secure the thickness of the AP die by replacing the PoP structure with a thin RDL substrate and setting thehigh Cu post. As shown in Fig. 1, when a die thickness over200um is applied with a thickness over 300um Cu post in aRDL-based FOPKG structure, the AP thermal resistance canbe reduced.

In this study, the world's thickest photoresist materialcapable of realizing a thickness over 350um was developedto apply the die thickness over 200um in the FOPKGstructure. The deep-hole via is realized with an optimalcomposition was developed by studying the lighttransmittance control of the thick photoresist andmaximizing the solvation of the developing part.

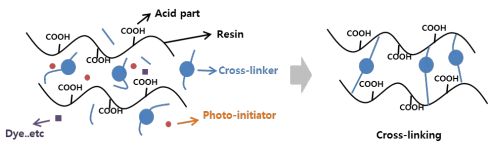

For high-speed Cu plating with high thickness, a negativetype photoresist with excellent chemical resistance wasselected. The main components of negative type photoresistconsist of a main polymer (resin), acrylate monomer as across-linker, and photo-initiator as shown in [Figure 2].

Fig1

Assuming that the photo-initiator content of X compositionhaving a light transmittance was 1.0, the photo-initiatorcontent was relatively decreased to increase the lighttransmittance. The higher the light transmittance, the higherthe degree of photo-polymerization in the lower part of thephotoresist, so it was possible to obtain via shape withoutundercut. Undercut was still confirmed in the compositionwith a light transmittance of 2.0, but a composition with alight transmittance of 4.0 achieved a straight profile with noresidue by controlling the amount of photo-initiator. And, when we went up to 8.0, footing shape and residue wereconfirmed due to a lower amount of photo-initiator. Fromthis result, it was found that the lower profile changed fromundercut to footing as the amount of photo-initiatordecreased. In this study, Y composition having a lighttransmittance of 4.0 was selected.