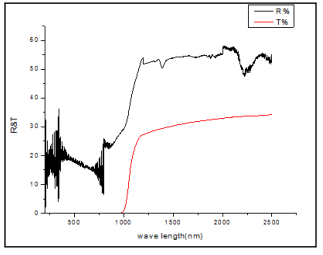

Porous silicon (PS) was prepared by electrochemical etching method. Mirage effect in transverse photothermal deflectionPTD ( skimming configuration) was used to determine thermal conductivity the experimental results of PS thermal conductivitywas compared with theoretical results they were almost the same. Optical extinction coefficient and absorption coefficient werecalculated from transmittance T and reflectance R curve which measured with UV-Vis-NIR Spectrophotometer, and they wereused to calculate the optical conductivity and electric conductivity from the Shankar and Joseph equations, and opticalconductivity and electric conductivity were studied with porosity in porous silicon.

Porous silicon has attracted considerable researchinterest after their discovery in 1956 [1]. Low-dimensionalmaterials are finding ever-widening application in many areasof science and Engineering [2]. Nanostructured poroussilicon shows a variety of other interesting properties,including tunable refractive index, tunable energy gap, lowlight absorption in the visible, high internal surface, variablesurface chemistry, or high chemical reactivity. Properties,along with its ease of fabrication and the possibility ofproducing precisely controlled layered structures make thismaterial adequate for its use in a wide range of fields, such asoptics, micro- and optoelectronics, chemical sensing orbiomedical applications.

Porous silicon samples were prepared by electrochemicaletching method of p-type cubic silicon wafers (c-Si), (100)orientation with resistivity of 0.01-40 Ω·cm, electrochemicaldissolution of Si wafers is used: HF-ethanol (measured byvolume) aquas with concentration from 20% . The currentdensity was always kept Constant for each sample duringetching of PS (10,..,50 mA/cm2).Fabricating process done in a normal etching Teflon cell fig(1). After anodization, PSsamples are carefully removed from the bath and cleaned indeionized water . Few examples of AFM measurement ispresented to show differences between samples according topreparing current (fig.2).

The decreasing in Thermal conductivity is attributed to that:The solid contribution is normally significantly higher thanthat of the gas contained in the pores, and thus, the gaseousconduction contribution is considered to be negligible. Theradiative contribution, krad, is derived from heat radiatedthroughout the pores, and is highly dependent on theporosity, pore size, and temperature [15]. For all that reasonsthermal conductivity in bulk silicon is higher than that of PSsamples. fig(4) shows the measured and theoreticalcalculated thermal conductivity of PS sample they arealmost the same.

Fig1

Porous silicon samples were prepared by electrochemicaletching method , HF-ethanol concentration from 20% ,Thecurrent density was (10,..,50 mA/cm2).Fabricating processdone in a normal etching Teflon cell, Mirage effect intransverse photothermal deflection PTD ( skimmingconfiguration) is used to determine effective thermalconductivity . It changed from120W/Mk for 8% porosity to47.2 W/Mk for 69 % porosity. Experimental results of PSthermal conductivity with porosity was compared withtheoretical results and it was almost the same . Absorptioncoefficient was calculated from transmittance T andreflectance R curve measured with UV-Vis-NIRSpectrophotometer was used to calculated extinctioncoefficient then to calculate electric conductivity and opticalconductivity, our work shows that absorption coefficient andthe extinction coefficient decreases with porosity increases.So is electric conductivity, while optical conductivity remainsconstant in rang of our porosity.