In this study, a miniaturized high fundamental frequency quartz crystal microbalance (QCM) is fabricated for sensor applications using a wet etching technique. The vibration area is reduced in the fabrication of the high frequency QCM with an inverted mesa structure. To reduce the complexity of the side wall profile that results from anisotropic quartz etching, a rectangular vibration area is used instead of the conventional circular structure. QCMs with high Q values exceeding 25,000 at 47 MHz, 27,000 at 60 MHz, 24,000 at 73 MHz and 25,000 at 84 MHz are fabricated on 4 × 4 mm2 chips with small vibration areas of 1.2 × 1.4 mm2 . A PMMA-based flow cell is designed and manufactured to characterize the behavior of the fabricated QCM chip in a liquid. Q values as high as 1,006 at 47 MHz, 904 at 62 MHz, 867 at 71 MHz and 747 at 84 MHz are obtained when one side of the chip is exposed to pure water. These results show that fabricated QCM chips can be used for bio- and chemical sensor applications in liquids.

To facilitate mass-production and lower the fabrication costs of QCM chips, the design area of a single QCM chip is set at 4 × 4 mm2 . The design etching area is 1.2 × 1.4 mm2 . The initial AT cut wafer is 100 µm thick (to produce the resonance at 16.7 MHz frequency). The design dimensions of the excitation electrode on the front side of the chip range from 200 to 800 µm in diameter with a 100-µm interval. Figure 2 shows the detailed microfabrication process: (1) the quartz wafer is washed using a piranha solution (H2SO4: H2O2 = 3:1) at 110 °C, followed by sputtering Au/Cr (100 nm/40 nm) bi-layer metal films onto the wafer to form an etching mask; (2) Au/Cr metal layers are patterned on the back side of the wafer, followed by photoresist removal; (3) a resist pattern is formed on the front side of the wafer to serve as the front side excitation electrode; (4) the quartz wafer is wet-etched using a saturated ammonium bifluoride solution at 85 °C, followed by Au/Cr etching and photoresist removal treatment; (5) Au/Cr is sputtered on the back side of the wafer to form the back side excitation electrode.

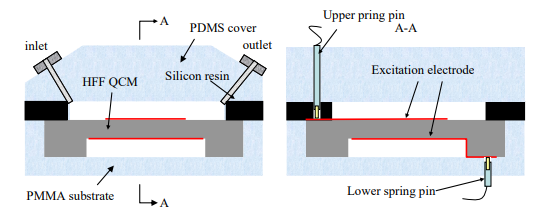

The vibration characteristics (i.e., the Q value, the equivalent circuit parameters, and the condition of the spurious modes near the primary TSM vibration) of the fabricated QCMs are directly evaluated by using an Agilent 4294A impedance analyzer with a 16034G test fixture, as shown in Figure 3. The sweep number is set to 800, and the scanning precision is set at the highest possible value. A flow cell is designed and fabricated to ensure that the chip can be used in practice as a bio- or chemical sensor in a liquid. The custom-designed flow cell consists of a PDMS cover, a thin silicon resin layer, and a PMMA substrate as shown in Figure 4. Liquid can be introduced through inlet and outlet ports in the PDMS cover. The silicon resin layer functions both as a sealing material and a cell chamber. A 100-μm deep cavity is created in the PMMA substrate to stabilize and hold the QCM chip. The excitation electrodes on the two sides of the chip are guided out using two spring-pins, each of which is fixed into a PDMS and PMMA substrate. A simple labview-based program is developed for data acquisition to examine the frequency stability and noise level.

HFF QCMs of 47 MHz, 60 MHz, 73 MHz, and 84 MHz were obtained. Figure 5 shows a fabricated QCM. Figure 5a,b is optical images of the top view and back view of the QCM, respectively. Figure 5c is a close-up image of the etched rectangular area, and Figure 5d is a representative image of the etched side wall profile, which is much simpler than in the circular version.

Fig1

High fundamental frequency QCMs with high Q values up to 25,000 for 47 MHz, 27,000 for 60 MHz, 24,000 for 73 MHz, and 25,000 for 84 MHz resonators were developed in this study. To our knowledge, ours is the first report on fabricating a QCM with an area below 4 × 4 mm2 , and in particular with a small rectangular etching area of 1.2 × 1.4 mm2 using a cheap wet etching process. A PDMS micro-flow cell was designed and fabricated to test the fabricated HFF QCM chips. The flow cell was used to measure Q values of 1,006 at 47 MHz, 904 at 62 MHz, 867 at 71 MHz, and 747 at 84 MHz respectively in water, which are suitable for chemical, and bio-sensors applications in liquids.

Financial support for this work was provided by the Ph.D. Programs Foundation of the Ministry of Education of China (Grant No. 20110092120052), the Natural Science Foundation of Jiangsu Province (Grant No. BK2011607), and the Fundamental Research Funds for the Central Universities.