Abstract

With the advantages of large electro-optical coefficient, wide transparency window, and strong optical confinement, thin-film lithium niobate (TFLN) technique has enabled the development of various high-performance optoelectronics devices, ranging from the ultra-wideband electro-optic modulators to the high-efficient quantum sources. However, the TFLN platform does not natively promise lasers and photodiodes. This study presents an InP/InGaAs modified uni-traveling carrier (MUTC) photodiodes heterogeneously integrated on the TFLN platform with a recordhigh 3-dB bandwidth of 110 GHz and a responsivity of 0.4 A/W at a 1550-nm wavelength. It is implemented in a wafer-level TFLN-InP heterogeneous integration platform and is suitable for the large-scale, multi-function, and high-performance TFLN photonic integrated circuits.

Introduction

Integrated photonicsis a discipline of integrating devices such as waveguides, lasers, photodetectors on a single chip. Due to fast and efficient transmission and processing of information, integrated photonics holds a significant potential for applications in communication, computing, and sensing. It offers several advantages such as low cost, low power consumption, and scalability . While materials like silicon, silicon nitride (Si3N4), and indium phosphide (InP) have been widely used as the photonics integration platform, lithium niobate (LN) has still gained considerable attention due to its strong electrooptic coefficient, large nonlinearity, and wide transparency window. However, as a photonics integration platform, traditional bulk LN material facesseveral challenges such as weak mode confinement, large footprint, and reduced nonlinear efficiency . To overcome these challenges, thin films lithium niobate (TFLN) technique has emerged as a solution. Thanks to the large refractive index difference between LN device layer and SiO2 BOX layer, TFLN technique enables tight mode confinement and high nonlinear efficiency, leading to its wide adoption in optical communications, microwave photonics, THz communications, and quantum photonics.

Followed by the commercial availability of high-quality TFLN wafers and the breakthrough of its fabrication technique, TFLN technique is implemented to develop various optoelectronics components, such as compact and high-performance modulators , broadband optical frequency combs, polarization management devices , and efficient wavelength converters. Most of these TFLN devices use external lasers and photodetectors since the LN material does not natively provide a light source and photodetection. This is one challenge faced by the TFLN technique as a potential universal photonics integrated circuits (PICs) platform. The flip-chip bonding technique was recently applied to integrate the InP distributed feedback (DFB) laser die with a pre-fabricated TFLN modulator chip19 . Low-loss and high-power TFLN-InP transmitters were achieved by optimizing the overlap between the respective platform modes. Besides, as an important optoelectronic conversion device, highperformance integrated photodiodes are essential for the TFLN integration platform. Amorphous silicon photodetectors integrated on TFLN platform was achieved within the visible wavelength range. It features a bandwidth of 10 MHz and responsivity of 22 mA/W to 37mA/W over the wavelengths spanning from 635 nm to 850 nm. The photodiodes working in the wavelength range of the optical communication is still needed to be explored.

Results

Structure and design

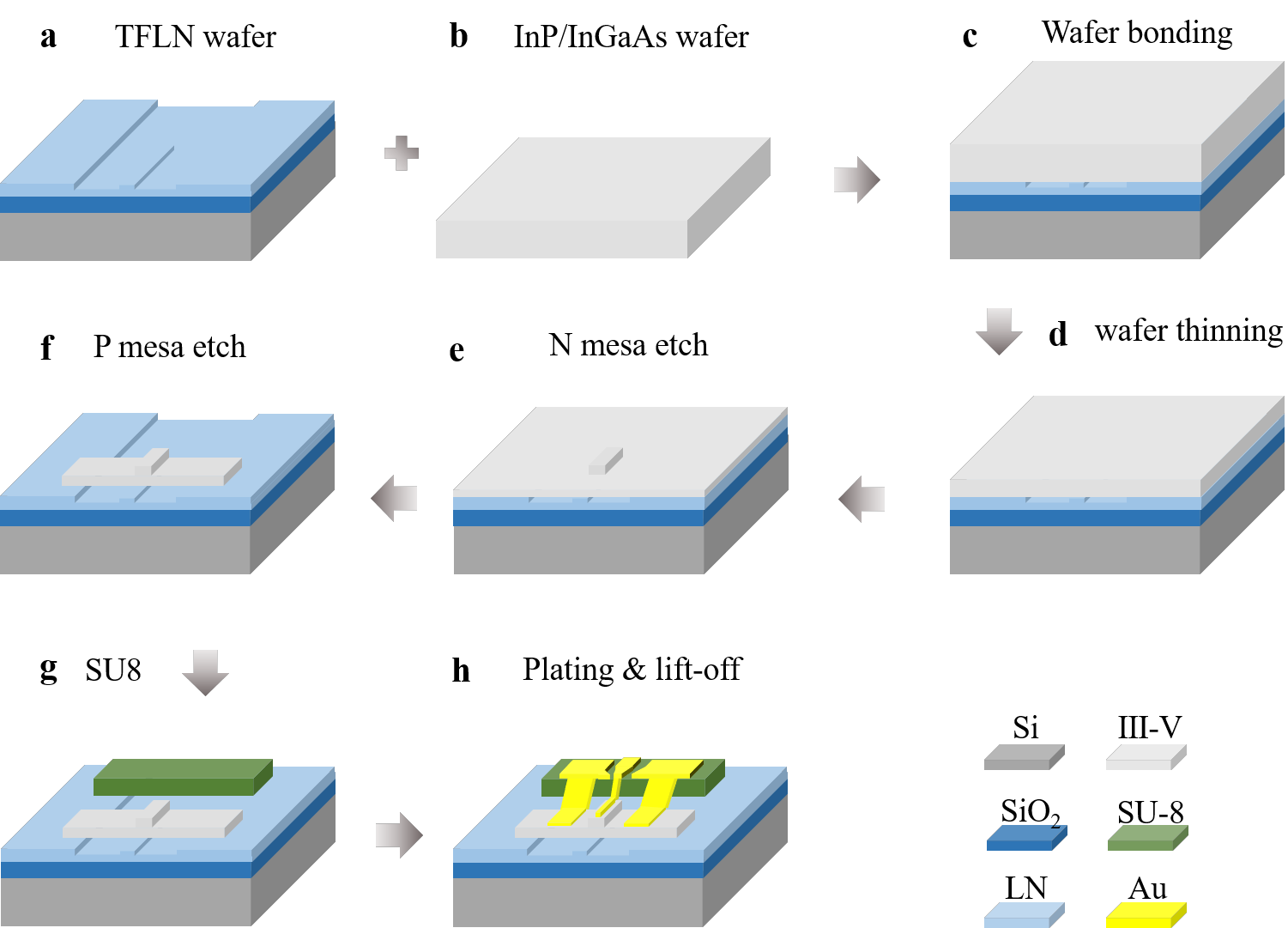

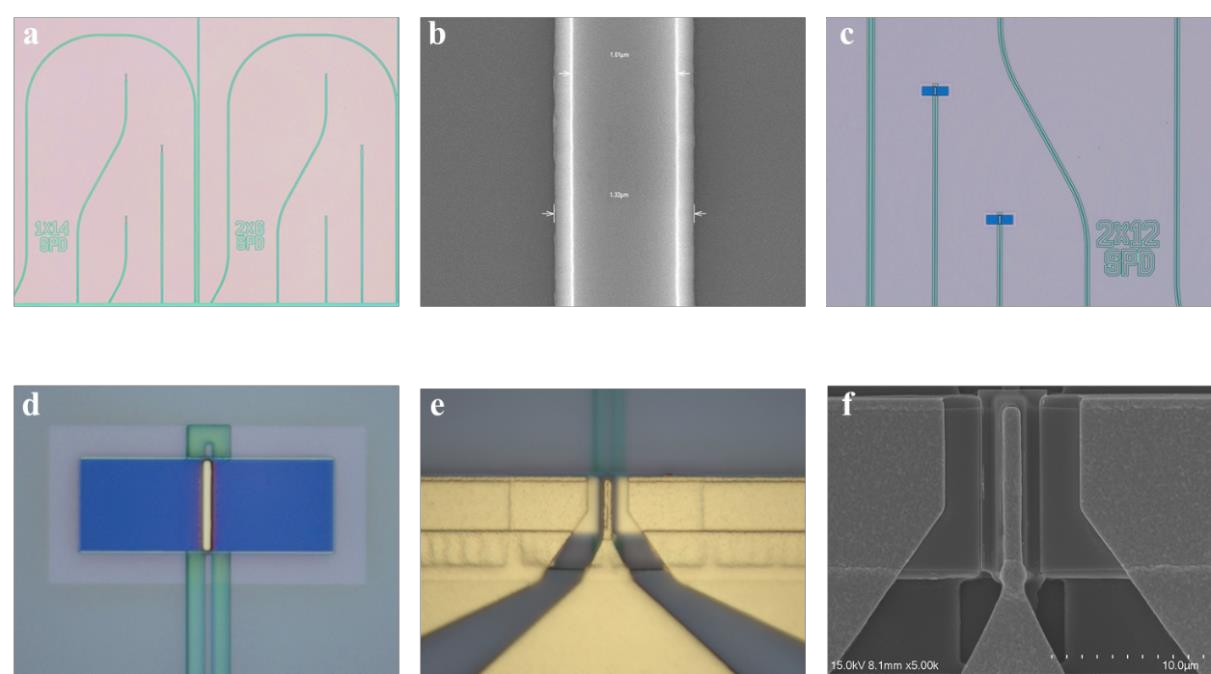

Figure 1 illustrates the designed fabrication process of the heterogeneously integrated photodiodes on the TFLN wafer, which includes wafer bonding, Ⅲ-Ⅴ material etching, and electrode fabrication. Initially, the LN waveguide was obtained by dry etching. The width of the fabricated LN waveguide is approximate 1um. The slope of the waveguide sidewall is approximate 63 degrees. Microscope and scanning electron microscope (SEM) images of the LN waveguide can be seen in Fig. 2a, b, respectively. Subsequently, an InP/InGaAs wafer was bonded onto the TFLN wafer with pre-defined waveguides and passive components. A combination of dry and wet etching techniques is utilized to etch Ⅲ-Ⅴ material, forming the n- and p- mesa while avoiding undercut and waveguide damage. The etched n mesa and p mesa is shown in Fig. 2c, d. Finally, a metal layer was electroplated as an electrode shown in Fig. 2e, f. Further details of the fabrication process can be found in the Materials and Methods section. The heterogeneously integrated MUTC PD with active areas of 2 μm × 6 μm, 2 μm × 8μm, 2 μm × 10 μm, 2 μm × 12 μm and 2 μm × 14 μm were fabricated.

Fig. 1. The designed process flow used to fabricate the waveguide-coupled photodiodes on the TFLN platform. a TFLN wafer with pre-defined waveguide and passive components, b bare InP/InGaAs wafer, c InP/InGaAs wafer and TFLN wafer bonding, d InP/InGaAs wafer substrate removal, e N mesa dry etch, f P mesa dry etch, g SU8 base for CPW pad, and h metal electroplating and lift-off.

Fig. 2. Microscope a and SEM b images of the LN waveguide, c, d, microscope images of the devices after n-mesa and p-mesa etching, microscope e and SEM f images of the fabricated photodiodes.

Measurement results and analyses

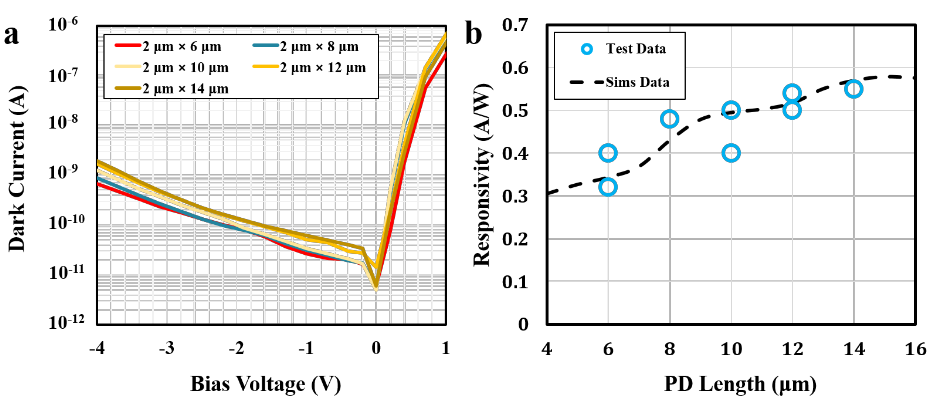

Firstly, we carried out the measurement of the dark current of the fabricated PDs. Figure 3a shows the dark current versus the bias voltage of the devices with active areas of 2 μm × 6 μm ~ 2 μm × 14 μm. The typical dark current of the devices is approximately 1 nA at -4 V bias. Next, the internal responsivity of the waveguide coupled PDs was characterized. The fiber-to-waveguide coupling loss and waveguide loss were measured to calculate the internal responsivity of the devices. A lensed fiber with a spot size of 2.5 μm was used to couple the light into and out of the loopback waveguides near the target photodiodes. The coupling loss and waveguide propagation loss were approximately 7 dB. The photocurrent was measured by coupling light into the photodiode near the loopback waveguide. At the wavelength of 1550 nm, the internal responsivities of the devices with lengths of 6 ~ 14 μm were 0.4, 0.48, 0.5, 0.54, and 0.55 A/W, considering the measured coupling loss and waveguide propagation loss, as shown in Fig. 3b. The measured responsivities of the devices are consistent with the simulated ones. When the PD length increases, the responsivity saturates due to the intrinsic absorption of the metal stack. The absorption of the metal stack can be mitigated by optimizing the thickness of the cladding layer.

Fig. 3. a I-V curves of the devices with active areas of 2 μm × 6 μm ~ 2 μm × 14 μm, b measured and simulated responsivities of the devices with lengths of 6 ~ 14 μm.

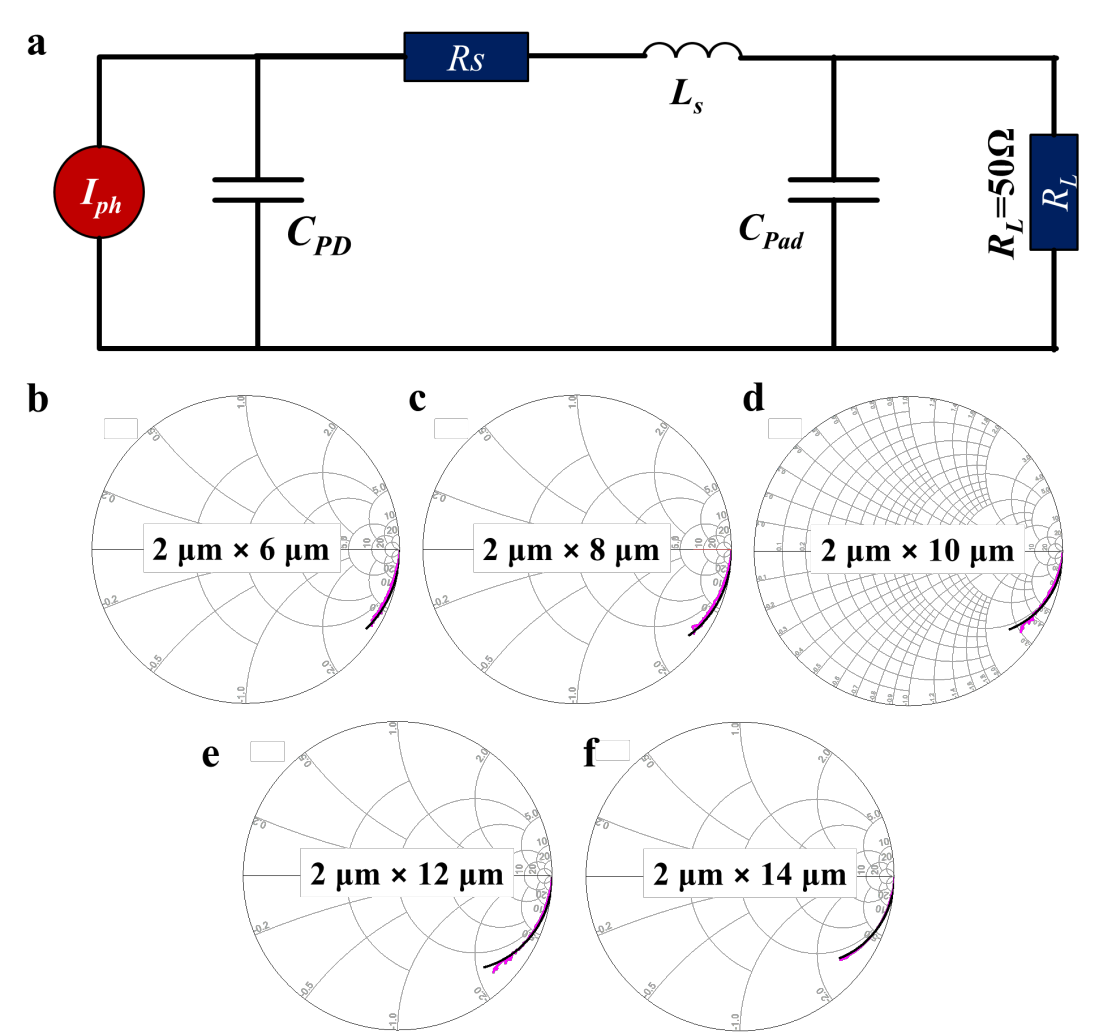

The S parameter of the devices was measured by a vector network analyzer with a frequency range of DC ~ 67 GHz. By fitting the measured S parameters to the equivalent circuit model as shown in Fig. 4a, the resistance and capacitance of the devices were extracted. The measured and fitted S11 curves of the devices with active areas of 2 μm × 6 μm ~ 2 μm × 14 μm at -4 V bias voltage are presented in Fig. 4b-f. The physical parameters extracted from the measured S11 and the Lumerical 3D model are shown in Fig. 5. The fitted parameters of the devices with different active areas and lengths are consistent with the simulation results. The fabricated photodiodes on the TFLN platform exhibit low junction capacitance but relatively large series resistance which is dominated by the resistance on p-mesa.

Fig. 4. a Equivalent circuit model of the devices for S11 fitting and frequency response simulation. Iph, CPD, Rs, Cpad, and Ls represents the frequency-dependent current source, junction capacitance, series resistance, and the capacitance and inductance of the CPW pattern, respectively. b-f Measured (red solid line) and fitted (black solid line) S11 curves (frequency range: 1 ~ 67 GHz) for devices with active areas of 2 μm × 6 μm ~ 2 μm × 14 μm at -4 V bias voltage.

Discussion

This paper presents ultra-wideband waveguide-coupled MUTC photodiodes heterogeneously integrated on the thin-film lithium niobate platform. The bandwidths of the devices with active areas of 2 μm × 6 μm, 2 μm × 8 μm, 2 μm × 10 μm, 2 μm × 12 μm, and 2 μm × 14 μm were 110, 105, 100, 101, and 97 GHz, respectively. The bandwidth of the devices is limited by the transit time of the photo-generated carriers. The carrier transit time can be reduced by optimizing the thickness of the absorption layers and incorporating a diffusion block layer. Another factor limiting the device bandwidth is the large series resistance on p mesa. An InGaAs layer can be added as p contact to reduce the contact resistance and thus larger RClimited bandwidth. By taking these practices, it has the potential to boost the total bandwidth of the devices up to 200 GHz. The measured responsivities of the devices with lengths in the range of 6 ~ 14 μm were 0.4, 0.48, 0.5, 0.54, and 0.55 A/W. The intrinsic absorption of the metal stack sets the upper limit for the responsivity of the devices. An optimized thicker cladding layer with a moderate doping level could mitigate the absorption of the metal stack and achieve a higher responsivity. The devices were applied to a data transmission system, and the obtained results showed their ability to detect 32 Gbaud PAM4 signal with high quality. It is demonstrated that the heterogeneously integrated photodiodes on TFLN platform have the potential to be applied in the next-generation high-speed transmission systems. This work paves the way to achieving massive-scale, multi-function, and high-performance TFLN photonic integrated circuits. Moreover, it holds a great promise for enabling ultra-high-speed optical communications, high-performance integrated microwave photonics, and multifunction integrated quantum photonics.

Materials and Methods Device fabrication

The whole fabrication process of the heterogeneously integrated photodiode starts from patterning LN waveguide and passive components by dry etching. A careful wet clean process is followed to ensure the cleanness of the TFLN wafer. Subsequently, a bare InP wafer was bonded onto the pre-patterned TFLN wafer. After wafer bonding, the InP substrate was mechanically thinned, followed by wet etching to remove the remaining part and expose the heavily doped InGaAs n-contact layer. N-mesa etch was performed to stop precisely at the InGaAsP p-contact layer by combining dry etching and selective wet etching. This step defined the size of the active region. The self-alignment method was applied in the fabrication process to ensure a precise alignment between the active region and the LN waveguide. P-mesa etching was performed using dry etching and selective wet etching to remove the InGaAsP above the LN wafer. In order to ensure the surface cleanness of the exposed LN wafer region, a wet chemical clean process is performed. A 3-μm-thick SU-8 layer was deposited to form the base for the CPW pad. Metal electrodes with a GSG pad were formed by electroplating and lift-off. The wafer was finally diced into small chips and then the chips were laterally polished.

搜索“华林科纳行业观察”小程序查看完整内容,或者加微信13358064333/18106288187。