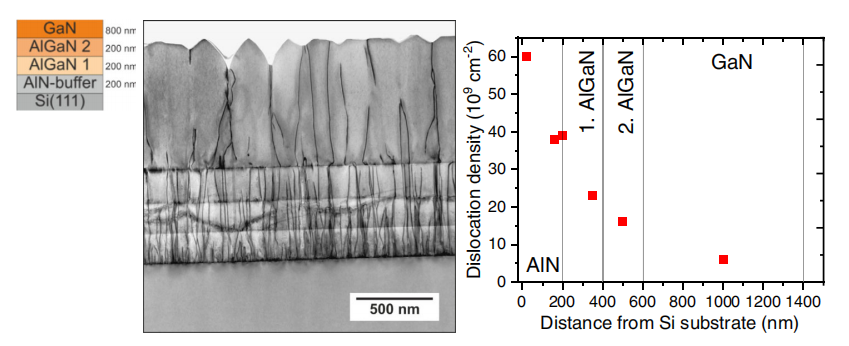

Si上 AIN 和 GaN 的溅射外延(111)

Sputter epitaxy is a low-cost process suited for the deposition of group-III-nitride semiconductors and allowing the deposition on large substrate areas at lower growth temperatures than in metal–organic vapor phase epitaxy (MOVPE). Highquality AlN, AlGaN, and GaN epitaxially grown on Si(111) substrates by reactive magnetron sputtering are demonstrated and details on process parameters are given. With an ammonia-based reactive sputtering process in a high-purity environment, AlN can be grown with high crystalline quality comparable to the best MOVPE-grown samples regarding twist and tilt and with a very low surface roughness, free of the typical columnar structure of sputtered AlN and pits.

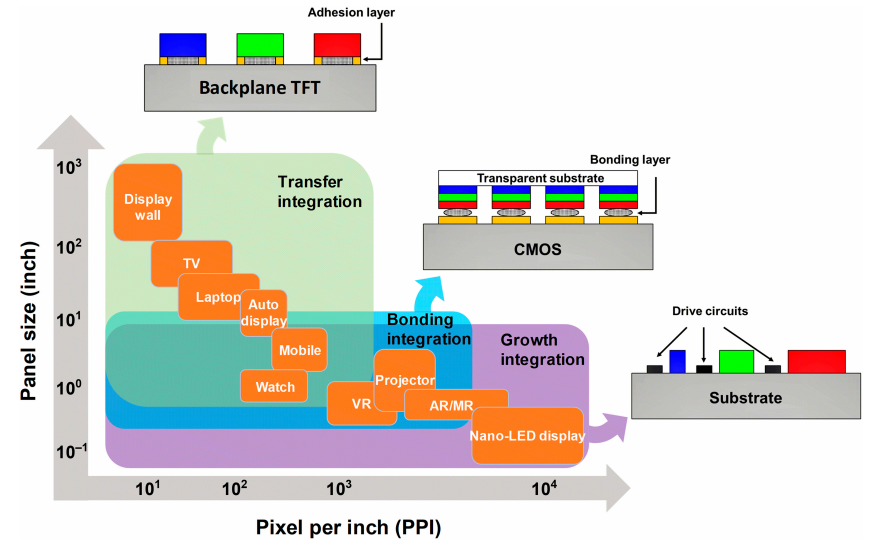

下一代显示器的Micro-LED集成技术

Inorganic micro light-emitting diodes (micro-LEDs) based on III-V compound semiconductors have been widely studied for self-emissive displays. From chips to applications, integration technology plays an indispensable role in micro-LED displays. For example, large-scale display relies on the integration of discrete device dies to achieve extended micro-LED array, and full color display requires integration of red, green, and blue micro-LED units on the same substrate. Moreover, the integration with transistors or complementary metal-oxide-semiconductor circuits are necessary to control and drive the micro-LED display system. In this review article, we summarized the 3 main integration technologies for micro-LED displays, which are called transfer integration, bonding integration, and growth integration. An overview of the characteristics of these 3 integration technologies is presented, while various strategies and challenges of integrated micro-LED display system are discussed.

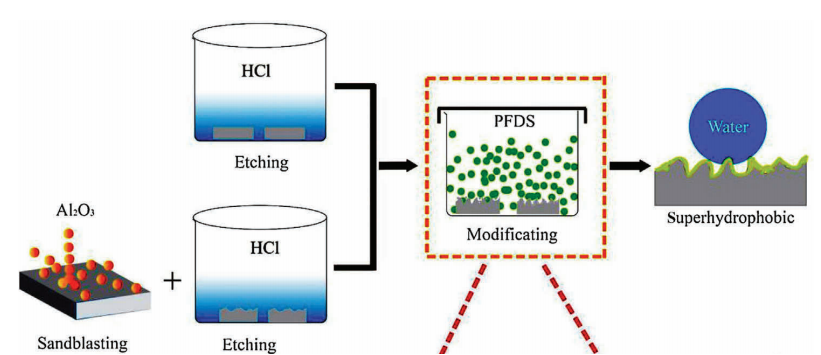

化学刻蚀法制备金属超疏水表面及其应用研究进展

In this paper, the action mechanism and the current research status of MSHPS were reviewed through the following aspects. Firstly, the model of wetting theory was presented, and then the progress in MSHPS preparation through chemical etching method was discussed. Secondly, the applications of MSHPS in self-cleaning, anti-icing, corrosion resistance, drag reduction, oil–water separation, and other aspects were introduced. Finally, the challenges encountered in the present application of MSHPS were summarized, and the future research interests were discussed.

关键词:金属、超疏水表面、化学蚀刻、低粘附性、自清洗、Micro-LED、下一代显示器、集成技术、硅、氮化镓