Abstract

In this study, we investigated the effect of Ar/He mixing ratio in the tetrafluoromethane/perfluorocyclobutane/Ar/He gas mixture on plasma parameters, SiO2 etching kinetics, and etching selectivity with respect to the amorphous carbon layer (ACL) mask in the inductively coupled plasma system with the low frequency (2 MHz) bias source. It was found that the type of dominant carrier gas does influence the output process characteristics through changes in both ion flux and CFx/F ratio determining the plasma polymerizing ability. In particular, He‐rich plasmas exhibited better performance with respect to the faceting of ACL mask and SiO2/ACL etching selectivity.

1、INTRODUCTION

Ultra‐large integrated circuit (IC) technology is being continuously developed to improve the performance of IC devices. It is known that the performance of these IC devices is directly connected with their pattern size that determines both feature sizes of active elements and integration degree. The modern tendency of IC technology assumes the transition toward smaller feature sizes and thus, requires the production of precise nanopatterns with the size of the order of several tens of nanometers or less. That is why the development and optimization of patterning techniques is the key problem for future progress in IC technology.

2 、EXPERIMENTAL SETUP AND PROCEDURES

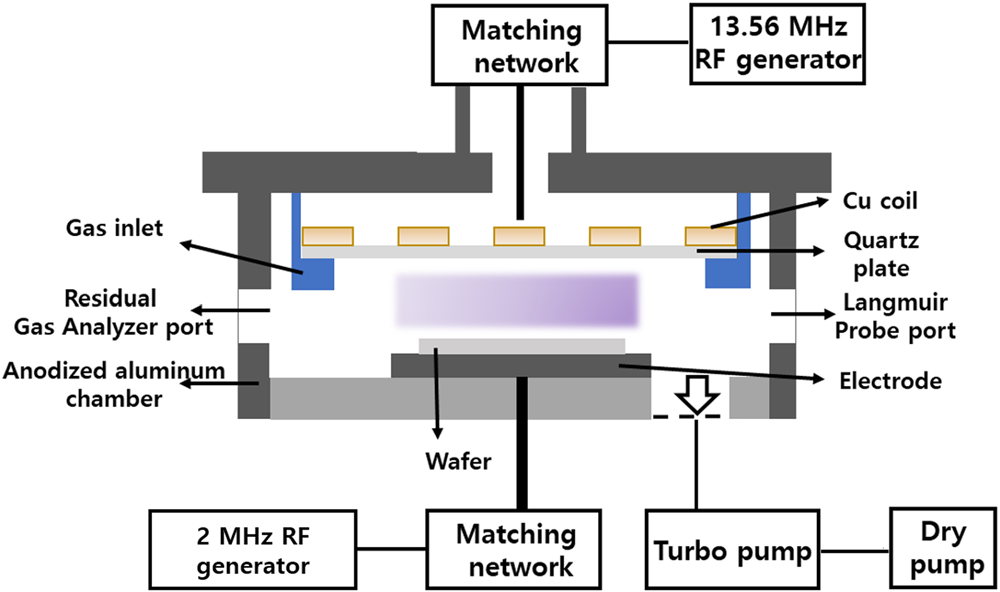

Figure 1 shows the schematic diagram of the ICP system used in this work, the details of which are described in previously published papers. Plasma was excited using the 13.56 MHz power supply connected to the flat 3.5‐turn copper coil on the top side of the reactor chamber. Another 2 MHz RF generator (advanced energy, CESAR RF power generator) powered the lower electrode to produce the negative bias voltage, −Udc. The temperature of the lower electrode was maintained at ∼0°C using the built‐in isopropyl alcohol flow‐cooling system.

FIGURE 1 Schematic diagram of inductively coupled plasma etching system.

Experiments were conducted with the CF4/C4F8/Ar/ He gas mixture at a constant total gas flow rate of 144 sccm, gas pressure of 6 mTorr, source power of 150 W, and bias power of 600 W. Flow rates for CF4 and C4F8 gases were fixed at 3 and 11 sccm, respectively, while the Ar/He flow rate ratio was the variable parameter. In particular, the change in He flow rate from 0 to 130 sccm allowed one to adjust the He fraction in the noble gas couple from 0% to 100%. Accordingly, the overall He content in a feed gas was 0%–90%.

3、RESULTS AND DISCUSSION

It is known that the overall effect of any RIE process in fluorocarbon gas plasmas depends on the kinetics of both chemical and physical etching pathways. The chemical pathway is controlled by the F atom flux but appears to be sensitive to the fluorocarbon film thickness that may limit the access of etchant species to the target surface. The physical component is controlled by ion flux and ion energy, where the latter affects sputter yields, surface damage, and etching profile features. Therefore, the question of primary importance is to understand how the Ar/He mixing ratio influences electrons‐ and ions‐related plasma parameters determining densities of plasma active species and the intensity of ion bombardment.

From plasma diagnostics by Langmuir probes, it was found that the transition toward He‐rich plasmas causes an increase in electron temperature (Figure 2a), but reduces ion current density (Figure 2b). The first effect reasonably results from decreasing electron energy losses in electron‐impact process with He atoms compared with those for Ar. The reason is that both excitation and ionization of He is characterized by higher threshold energies and lower absolute cross‐sections. At the same time, the relatively weak effect of the He fraction on Te is because of essential nearly constant electron energy losses for vibration and low‐threshold electronic excitation of fluorocarbon species. A decrease in j + mentioned in Figure 2b follows the same behavior of total ion density while the latter changes according to decreasing total ionization rate. The reason is that the He atoms are featured by much higher ionization potential (24.6 eV compared with 15.8 eV for Ar) as well as exhibit much lower ionization rate coefficients at a given electron temperature (∼2.6 × 10−12 cm3 /s compared with ∼2.4 × 10−10 cm3 /s for Ar at Te = 3 eV). Such a situation suggests also that an increase in He fraction in a feed gas does not mean the same behavior of He+ ion fraction inside n+. According to our estimations, the latter does exceed 10%, so that the effective ion molar mass Mi demonstrates the only weak decrease toward He‐rich plasmas (45–33 for 0%–100% He in Ar + He). As a result, the nearly constant ion Bohm velocity provides no principal difference between changes in n+ and j +, as shown in Figure 2b. From Figure 2a, it can be seen also that the substitution of Ar for He leads to weakly increasing bias voltage that produces the same tendency for the ion bombardment energy ε = | eU U − − | i f dc , where U fT f e = () is the floating potential. The reason is that the negative charge induced by the bias power source under the condition of Wdc = const is partially compensated by positive ions coming from bulk plasma. Therefore, the general rule is that the lower ion flux Γ ≈ j e/ + + , the higher remaining negative potential on the bottom electrode. Earlier, several works have suggested that the intensity of ion bombardment may be traced by the parameter M ε Γ i i +, where the multiplicand under the square root reflects the momentum transferred from the incident ion to the surface atoms. In our case, this parameter decreases monotonically in the range of 2.6 × 1017–1.4 × 1017, or by ∼1.9 times, for 0%–100% He in Ar + He couple. As such, a decrease in the ion bombardment intensity takes place.

FIGURE 2 Electrons‐ and ions‐related plasma parameters as functions of the He fraction in the noble gas couple: 1—electron temperature; 2—negative dc bias; 3—ion current density; 4—total positive ion density.

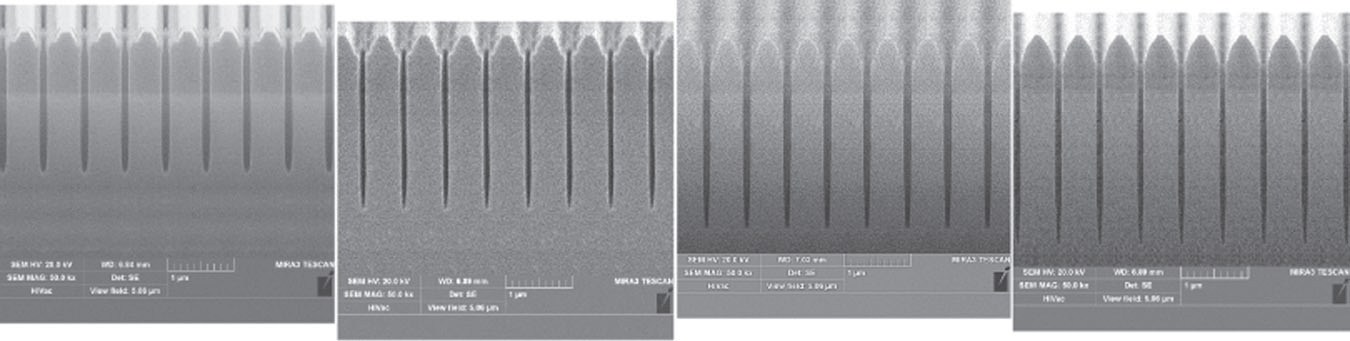

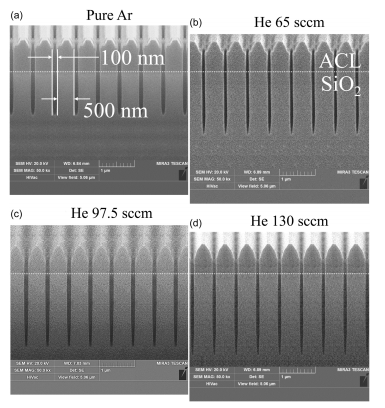

Figure 3shows ACL and SiO2 etching profiles at various Ar/He mixing ratios. In these experiments, we used the variable etching time to obtain comparable etching depths for various processing conditions. It can be seen that both Ar‐rich and He‐rich plasmas provide nearly excellent profile shapes, probably due to a combination of low gas pressure and high‐ion bombardment energy that ensures the low angular scattering of incident ions. The absence of principal differences between dominant noble gas components is in agreement with small changes in the effective ion mass, as was mentioned above. As such, the only feature of Ar‐rich plasma is the higher faceting of the ACL mask. Probably, such a phenomenon may be related to both higher physical etching components and thinner polymer film on the ACL surface. Anyway, the most important result is that the HAR etching of SiO2 may be achieved not only using the CCP, but is also possible in ICP with setting an appropriate processing conditions. The use of He carrier gas instead of conventional Ar allows one to reduce the faceting of the ACL mask as well as to increase the SiO2/ACL etching selectivity.

FIGURE 3 Etched profiles of: (a) pure Ar (130 sccm), (b) He (65 sccm), (b) He (97.5 sccm), and (d) He (130 sccm).

4 、CONCLUSIONS

In this study, we investigated the effect of noble gas ratio in CF4/C4F8/Ar/He plasma on SiO2 etching kinetics, selectivity in respect to the ACL mask and etching profile features. Experiments were carried out in the ICP system using a low‐frequency (2 MHz) bias source. Plasma parameters were examined by Langmuir probes and OES. It was found that the substitution of Ar for He reduced the plasma density and lowers the ion bombardment intensity as well as increases both CFx/F ration and polymer film thickness. It was suggested that the SiO2 etching process is mostly driven by the chemical etching pathway, and the latter is influenced by F atoms generated by ion bombardment inside the polymer layer. It was shown that (a) both Ar‐rich and He‐rich plasma provide vertical etching profiles; and (b) the use of He carrier gas instead of conventional Ar allows one reduce the faceting of ACL mask as well as to increase the SiO2/ ACL etching selectivity.