Abstract.

The present study demonstrates deposition of porous SiO2 thin films using combination of sol-gel, soft-templating and spin-coating methods. The recipe for Si-sol using TEOS (tetraethylorthosilicate) as a precursor was optimized in order transparent and stable sol to be obtained. Commercially available triblock co-polymer Pluronic 123 was considered as a soft template and its concentration and volume fraction to sol were varied. For achieving the final composition of silica films, different stepwise annealing regimes were implemented where the temperatures and duration of each step were optimized. Optical properties of films were calculated using nonlinear curve fitting of measured reflectance spectra in UV-VIS spectral range. Surface morphology and structure of the films were characterized by Transmission Electron Microscopy (TEM) and Selected Area Electron Diffraction (SAED). The porosity and optical sensing ability of the films were tested by measurement of their reflectance spectra prior to and during exposure to acetone vapors which served as probe molecules. The influence of soft template composition and annealing regimes on SiO2 properties were revealed and application of studied films as sensitive media for opto-chemical sensing was discussed.

1. Introduction

The demand of sensing media capable of detecting external stimuli is constantly increasing and their numerous applications force their development with different technologies to meet one’s requirements and needs. SiO2 is widely studied material and due to his widespread application it is still under great research interest . Quite often, silica is converted to porous form to functionalize the material for different applications. Mesoporous silica materials are the main carrier for drug delivery due to increased capacity for drugs loading, functionalized material for nonlinear photonics, waveguide sensors and others.

Porous materials are mainly synthesized by templates- organic (soft template) and inorganic (hard). Both methods have their advantages but simplicity is undoubtedly attached to soft template procedure and therefore many templates are being used for tailoring of porous materials properties.

2. Experimental details

2.1. Preparation of dense and porous SiO2 films The sol was obtained in a one-pot procedure using tetraethyl orthosilicate (TEOS) (>99%, pure for synthesis, Merck) as silica precursor, hydrochloric acid (37%, pure for analysis, Merck) as catalyst, ethanol (96%, pure for analysis, Merck) and distilled water as solvents. The sol was prepared from 6 ml TEOS dissolved in pre-mixed hydrochloric acid (0.2 ml), ethanol (4.4 ml) and distilled water (0.75 ml). The reaction mixture was stirred for 3 hours at 35°C and aged for 24 h at room temperature. Prior to the film deposition the aged sol is diluted with ethanol sevenfold in order to obtain SiO2 films with approximate thickness of 100 nm. Probe of 0.2 ml diluted sol is added dropwise on the pre-cleaned Si substrate and spin-coated at 4000 rpm for 60 s with preliminary step at 500 rpm for 1.5 s.

3. Results and discussions

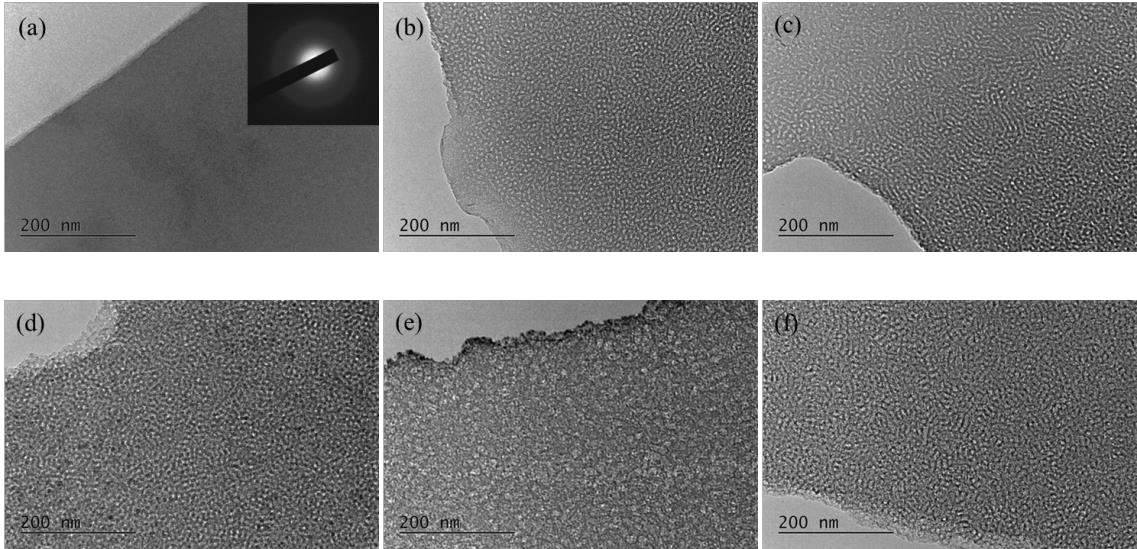

TEM images and SAED pattern (inset) of studied SiO2 films are presented in figure 1. The concentration of template (P123) is kept constant (10 wt%) while its volume fraction to sol, respectively to TEOS, was varied (table 1). Pore formation is a result of phase separation between the inorganic structure and pore forming agent. The template structuring is governed by Evaporation Induced Self Assembly (EISA). Initially, after deposition of the coating, the block copolymer is dispersed within the volume of the film. Due to evaporation of the solvent, the concentration of the polymer increases and above certain level, called critical micelles concentration the polymer chains start to aggregate in micelles that defined the shape and size of the pores. However, when number of micelles is large steric hindrance occurs that could explain why larger concentration does not lead to larger size of the pores. It is seen that by changing the volume fraction of P123 the size of pores and the pore-to-pore distance could be controlled. SAED patterns (in figure 1 only patterns for dense films are presented because for porous films they are similar) indicate that both dense and porous films are amorphous. Additional XRD measurements (for the sake of brevity not shown here) confirm the amorphous status of the films.

Figure 1. TEM images and SAED pattern (inset) of SiO2 films prepared from Si sol and templated with different volume fractions of block copolymer P123 to TEOS: a) 0% (dense film); b) 24%; c) 28%; d) 35%; e) 47% and f) 70%. The concentration of polymer is 10 wt%.

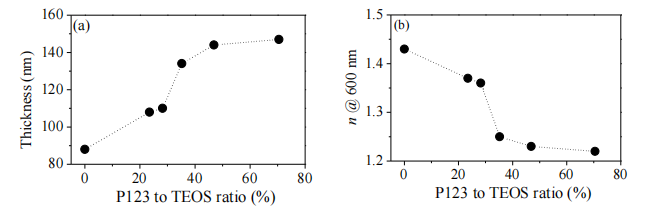

The influence of different volume fractions of polymer on refractive index and thickness of the films is shown in figure 2 (the detailed explanation of n and d determination is presented in section 2.3) and the particular values of n and d are included in table 1.

Figure 2. Silica films thickness (a) and refractive index at wavelength of 600 nm (b) as a function of volume fraction of triblock copolymer Pluronic P123 to TEOS.

The increase of volume fraction of P123 from 0 to 47% leads to increase of thickness with more than 60% (from 88 nm for dense film to 144 nm for porous one) and simultaneous decrease of refractive index from 1.43 for dense film to 1.23 for porous one templated with 47% P123. However, further increase of template does not lead to substantial change of thickness and refractive index. There is a very good correlation between the rates of thickness increase and refractive index decrease that means that free volume in the films increases with addition of polymer and that there is no collapse of the films during annealing. This is confirmed by the values of the free volume in the films, fair. It is calculated by Bruggemann effective medium approximation assuming film as an effective medium comprising two phases: SiO2 matrix with air (free volume) inside . As expected fair increases with addition of polymer and changes from 0 for dense film to 47 for 70 % templated one.

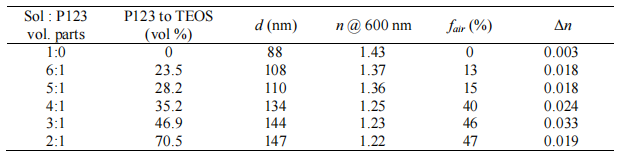

Table 1. Volume fraction of P123 to sol in volume parts and to TEOS in vol. %, thickness d (nm), refractive index n and free volume fair(%) of deposited SiO2 films and change in n due to exposure to acetone vapors - Δn.

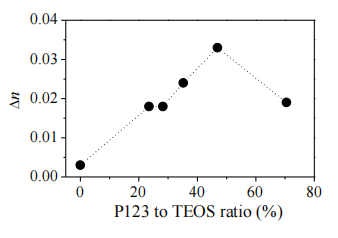

The change of refractive index due to exposure to acetone vapors is presented in figure 3 (details of measurements and calculation of Δn are presented in section 2.3). When film is exposed to acetone the vapors penetrate in the pores and condense. As a result effective refractive index of film increases because the medium with small refractive index (air with n=1) is replaced with higher refractive index medium (liquid acetone n=1.36). Considering that free volume in the films increases with addition of template someone may wrongly conclude that Δn should continuously increase. Actually in most cases there is an optimum value of template and further increase of overall porosity in the film does not result in improvement of sensing properties. Two factors are also important for the sensing medium – the surface area and the pore size, as they determine how easily would the vapors diffuse through the pores and condense onto the surface under fixed vapor concentration. In our experiments we have managed to find an optimum trade-off between all those parameters. It seems that the films prepared with 47% P123 to TEOS ratio have the highest pore size that would promote the easiest vapor condensation and the highest area of pore walls where physisorption takes place.

Figure 3. Change in refractive index due to exposure of films to acetone vapors as a function of volume fraction of triblock copolymer Pluronic P123 to TEOS.

4. Conclusions

The successful deposition of porous SiO2 thin films using combination of sol-gel, soft-templating and spin-coating methods is demonstrated. The porosity of the films and their refractive indices could be controlled by variation of volume fraction of soft template (Pluronic P123) towards the precursor for deposition of SiO2 films (TEOS). The free volume of the films varies from 0 for dense film to 47% for 70% templated films leading to change of refractive index from 1.43 to 1.22. The films templated with P123-to-TEOS volume fractions of 47% are the most suitable media for optical sensing. Temperature annealing at moderate temperatures (320oC) is recommended because higher temperature annealing leads to deterioration of sensing properties because of the partial collapse of the films.