ABSTRACT: Ultraviolet light-emitting diodes (LEDs) suffer from a low wall-plug efficiency, which is to a large extent limited by the poor light extraction efficiency (LEE). A thin-film flip-chip (TFFC) design with a roughened N-polar AlGaN surface can substantially improve this. We here demonstrate an enabling technology to realize TFFC LEDs emitting in the UVB range (280−320 nm), which includes standard LED processing in combination with electrochemical etching to remove the substrate. The integration of the electrochemical etching is achieved by epitaxial sacrificial and etch block layers in combination with encapsulation of the LED. The LEE was enhanced by around 25% when the N-polar AlGaN side of the TFFC LEDs was chemically roughened, reaching an external quantum efficiency of 2.25%. By further optimizing the surface structure, our ray-tracing simulations predict a higher LEE from the TFFC LEDs than flip-chip LEDs and a resulting higher wall-plug efficiency.

Light-emitting diodes (LEDs) emitting in the ultraviolet (UV) range have applications such as water disinfection, sterilization, resist curing, and medical treatments.1 In comparison to the prevalent mercury-based UV lamps, AlGaN-based UV LEDs are environmentally friendly, can be tailored for a specific application, and their form factor allows for a convenient integration.However, the low wall-plug efficiency (WPE) below 10% for UV LEDs with an emission wavelength below 350 nm still limits their use.

In the UVB range (280−320 nm), the external quantum efficiency (EQE) is affected by the low internal quantum efficiency due to the high threading dislocation density from the growth on AlN/sapphire templates and the involved relaxation process due to low Al-contents.3 Recent improvements in injection efficiency and light extraction efficiency have recently resulted in an EQE of almost 10%.4 The main limiting factor for the EQE is the light extraction efficiency (LEE), which is therefore the most important to improve.

The building blocks of the epitaxial structure are shown in Figure 1a, and the full structure is further described in Supplementary Note 1. The UVB LED with a p-side, transparent to the emitted light is grown on top of a sacrificial multilayer (a 118 nm thick Al0.37Ga0.63N layer and a five-period structure of alternating 5 nm thick Al0.11Ga0.89N and 5 nm thick Al0.37Ga0.63N), which is used to separate processed LED devices from the substrate later in the process. That multilayer is embedded between two etch block layers (uid and lowdoped Al0.50Ga0.50N) to confine the electrochemical etching and prevent parasitic etching.The integration of a low-Alcontent and high n-doping in the multilayer in combination with the unintentional doping of the top etch block layer and a Si concentration that is lower than that of the sacrificial layer, in this case 2 × 1018 cm−3 in the n-side of the LED, maximizes the etching selectivity. The sacrificial layer design with thin alternating low and high Al-contents allows for the use of lower Al-contents without degrading the crystal quality due to relaxation, which would happen in the case of a bulk layer. A low Al-content improves the etch selectivity between the sacrificial layer and the etch block layers, a selectivity that is further enhanced by the generated sheets of high carrier concentrations in the periodic structure created by the built-in polarization fields. Uniform electrochemical etching across the sample is achieved by including an n-doped current spreading layer below the bottom etch block layer.

Figure 1. (a) Building blocks of the epitaxial structure and (b) schematic design of a TFFC LED with a roughened N-polar AlGaN surface.

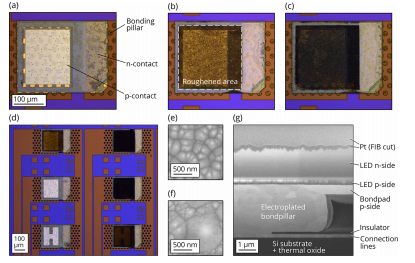

TMAH-based wet etching is used to roughen the exposed N-polar AlGaN surface for 9 and 15 min to achieve different degrees of surface roughening and to investigate its impact on the light extraction. Figure 2a shows an as-transferred TFFC LED, whereas Figure 2b shows a device after 9 min roughening and Figure 2c shows a device after a 15 min roughening. Figure 2d shows an LED array with different degrees of roughening.

Figure 2. Microscope images of (a) an as-transferred LED, (b) an LED wet-etched for 9 min, and (c) an LED wet-etched for 15 min. (d) A TFFC LED array after roughening of selected devices for both 9 and 15 min. Top-view SEM images of the N-polar Al0.5Ga0.5N surface after (e) 9 min and (f) 15 min roughening. (g) SEM cross-sectional view of roughened TFFC LED.

The peak wavelength of the electroluminescence spectrum for the as-grown, as-transferred, and roughened LEDs is within 306 ± 2 nm, as seen in Figure 3a, which indicates no major strain change during substrate removal and roughening. A similar variation in the peak wavelength is obtained across the as-grown wafer suggesting local inhomogeneities to be the cause of the small variation in peak wavelength between the devices. In addition, the full width at half-maximum is 10 ± 1 nm for all devices and above 320 nm the spectra of the roughened devices show a low parasitic luminescence.

Figure 3b shows the L−I−V characteristics for an astransferred device and two roughened devices after 9 min and 15 min roughening. The emission power of the device that has been roughened for 9 min has increased by around 24%. For 15 min roughening, there is no general improvement in emission power compared to 9 min roughening. This is attributed to a more inhomogeneous distribution in cone size which includes not only larger-sized cones but also smallersized ones compared to the 9 min roughened sample, as seen in the top view SEM images in Figure 2e,f. The I−V enhancement of 24% for 9 min and 25% for 15 min roughening. The surface roughening increases the maximum external quantum efficiency from 1.81% for as-transferred devices to 2.23% after a 9 min wet etching and 2.25% after a 15 min wet etching. Overall, a maximum wall-plug efficiency of 1.21% for 15 min of roughening is achieved.

Figure 3. (a) Normalized electroluminescence spectra for as-grown, as-transferred, and roughened devices. (b) L−I−V characteristics for an astransferred LED and two LEDs roughened for 9 and 15 min.

We have demonstrated thin-film flip-chip UVB LEDs using a lift-off technique based on lateral electrochemical etching to separate fully processed devices from the growth substrate. The sacrificial layer consisted of a multilayered structure, which enhanced the etch rate contrast to the surrounding layers, and combined with a suitable sample design with protective layers allowed for a reliable lift-off without parasitic etching. As a result, the electrical characteristic of the LED was not degraded by the electrochemical etching and bonding. The light extraction efficiency was increased when roughening the Npolar AlGaN surface of the TFFC LEDs, which increased the emission power by about 25% without degrading the I−V characteristics, resulting in an external quantum efficiency of 2.25%. Light-extraction simulations predict that an optimized roughening of the TFFC LEDs can further enhance the optical output power, but this would require an improved texturing method. Our TFFC LEDs demonstrate the potential of using electrochemical etching for substrate removal and a way forward to boost the WPE in UV LEDs.

下一篇: 碳化硅基板抛光整体解决方案