Present silicon carbide substrate polishing process including lapping, bulk polishing, and fine polishing. We are now providing the total solutions for bulk polishing, fine polishing, and cleaning. For bulk polishing slurries, it uses potassium permanganate as oxidant and alumina as abrasive which can provide Ra = 0.7 ~ 0.9 Å with high throughput. For fine polishing slurries, it uses colloidal silica as abrasive and hydrogen peroxide as oxidant, and it can further improve the Ra to 0.5 ~ 0.7Å. To remove the potassium permanganate and its water insoluble byproduct - manganese dioxide; we provide an acidic solution – GC13020 (pH = 1 ~ 2), it can quickly remove these manganese compounds from tool, pad and wafers. GC13020 can also remove the alumina particles which adsorbed on the surface of silicon carbide wafer, and its cleaning efficiency is better than 5% hydrogen peroxide solution.

Introduction

Silicon carbide is a compound composed of silicon and carbon. Its dielectric breakdown field strength is 10 times that of Si, and the energy gap width is 3 times that of Si. Based on these advantages, SiC are widely investigated as a power device material that exceeds the limit of Si. The use of SiC can realize a high voltage diode with a voltage of more than 600V through the SBD (Schottky Diode) structure, which is a device with high speed characteristics. Therefore, replacing FRD (Fast Recovery Diode) with SiC SBD can significantly reduce reverse recovery losses. The drift layer resistance of SiC devices is lower than that of Si devices, so high withstand voltage and low resistance can be achieved at the same time through MOSFETs with high-speed device. SiC power device equipped with SiC-MOSFETs and SiC-SBDs can significantly reduce switching losses caused by tail currents of IGBTs and reverse recovery currents of FRDs.

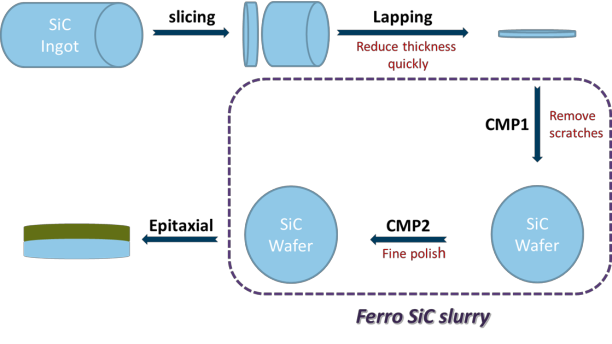

As showed in figure 1, general SiC polishing process including ingot slicing; lapping; bulk polishing and fine polishing. For lapping process, it needs rapidly reduce the thickness of SiC substrate to about 350 μm ~ 600 μm. Thus, diamond as abrasive based slurry is widely used in this process. Depended on different lapping process, it will cause different depth of scratches, and its range is about 1 ~ 2 μm. To remove the scratches caused by lapping process in bulk polishing step, it needs a slurry with high SiC removal rate and good roughness. Thus, a slurry which uses alumina as abrasive and potassium permanganate as oxidant is widely applied in bulk polishing step. Although the bulk polishing slurry can remove the scratches caused by lapping process, but it still causes some tiny scratches during bulk polishing step. Thus, fine polishing slurry is used to remove these tiny scratches. In general, fine polishing slurry uses colloidal silica as abrasive and hydrogen peroxide as oxidant, but the hardness of colloidal silica is smaller than alumina and the oxidative ability of hydrogen is weaker than potassium permanganate. Thus, fine polishing removal rate is much lower than bulk polishing removal rate.

Figure 1

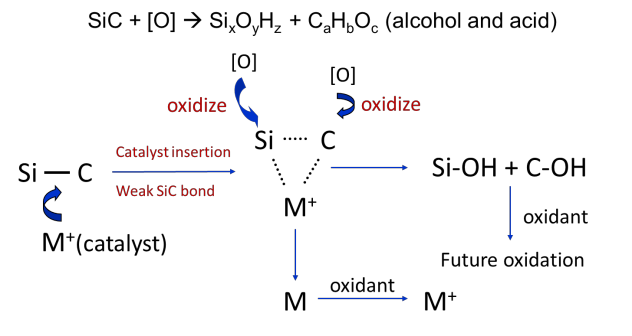

SiC removal mechanism for both bulk polishing slurry and fine polishing slurry are showing in figure 2. Metal ion is inserted into silicon carbon bond and then weakens the silicon carbon bond. Finally, -OH group replaces the Si – M – C bond to form Si-OH bond and C-OH bond. According to the oxidant type, C-OH may be further oxidized to COOH.

Figure 2

The solutions for bulk polishing

In general, bulk polishing process can be divided into two groups. One is single substrate polishing, and substrate size is over than 8 inches. The requirement for this group is high SiC removal rate being at least over than 8.0 um/h; the other is multiple substrate polishing, and its removal rate is about 1.0 um ~ 3.0 um/h which depends on their polishing recipe.

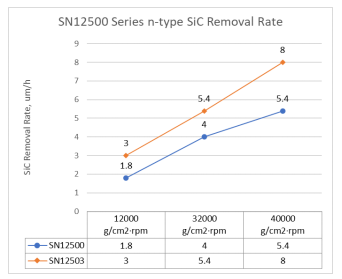

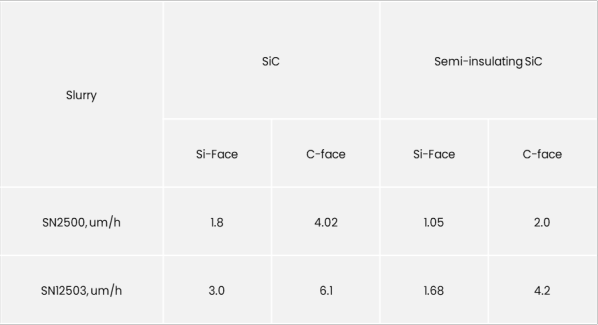

We are now providing SN12500 series bulk polishing slurry which can cover the requirements of two groups. As showed in table 1, SN12500 can provide 1.8 um/h SiC removal rate under lower mechanical force, and its roughness is about 0.7 ~ 0.9 Å with few tiny scratches. And SN12503 can provide higher throughput than SN12500 with similar roughness. It is also possible to further boost SiC removal rate over than 8.0 um/h under higher mechanical force.

Table 1

During the bulk polishing process, slurry is always used as “recycle use”. Thus, its pot life is very important because of cost concern. According to experiments, the SiC removal rate of SN12500 was dropped to 1.2 um/h after 5 hours passed. There are two root causes for SiC removal rate dropping during the polishing process. The first is the consumption of KMnO4. According to the analysis, KMnO4 dropped to 33% of original dosage after 5 hours passed, and this consumption didn’t only include the oxidation of SiC but also the oxidation of byproduct, and its mechanism is shown in equation 1 & 2 (equation is not balanced): SiC + KMnO4 → Mn2+ + S-OH + C-OH (1) KMnO4 + Mn2+ → MnO2 (2)

The second root cause is the coating of MnO2 on the alumina surface. Due to water insoluble of MnO2, it tends to coat on alumina surface during the polishing process which leads to SiC removal rate dropping. To demonstrate these assumptions, we added fresh KMnO4 into used SN12500 to its original dosage but SiC removal rate didn’t turn back to original level. We also prepared the MnO2 coated alumina, and we found that the more MnO2 coated, the more removal rate drop.

Semi-insulating SiC substrate is wildly investigated in recent years, and SN12500 series can also provide good throughput. Its data are showing in table 2.

Table 2

SiC substrate containing two face: silicon atom rich face (Si-face) and carbon atom rich face (C-face). C- face is more easily removed than Si-face and its data are showing in table 3. C-face removal rate is much higher than Si-face.

To use KMnO4 based slurry, polyurethane type hard pad is recommended to prevent the corrosion of KMnO4. On the contrary, poromeric fluff type soft pad is easily corroded by KMnO4. Besides, the glue used in back side or sub pad also needs anti-corrosive ability against KMnO4; otherwise the pad will be peeled off during the polishing process which leads to SiC substrate broken.

Table 3

The solution for pad/tool/substrate cleaning

Because KMnO4 and its byproduct (MnO2) is hard to be removed by water or hydrogen peroxide once it dried on tool, tank, or pad. Besides, waste KMnO4 pollution is another key issue in environmental concern. Thus, we have developed a cleaner - GC13020 which can rapidly convert KMnO4 and MnO2 to water soluble Mn2+ ion (as showed in figure 3), even it was already dried on the tool, tank, or pad.

Figure 3

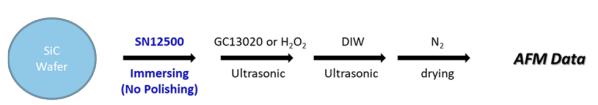

GC13020 can also remove alumina particle residual after SN12500 polishing.

Figure 4

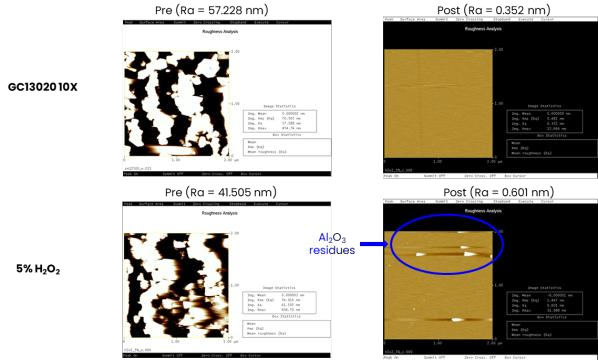

As showed in figure 4, we use 5% hydrogen peroxide solution as contrast. Immerse SiC substrate into SN12500 for 10 minutes, and then clean the SiC substrate by diluted GC13020 or 5% hydrogen peroxide solution under ultrasonic vibration condition, and finally dry with nitrogen gas. AFM image are showing in figure 5:

Figure 5

In contrast to GC13020 cleaning, 5% hydrogen peroxide solution cleaning still have some alumina residual and roughness is much higher than GC13020 cleaning.

The solutions for fine polishing

Fine polishing process is always adopted to further improve scratch defect and roughness. To achieves these targets, colloidal silica has been used as abrasive, and oxidant is depended on catalyst type, in general, hydrogen peroxide has been adopted as oxidant.

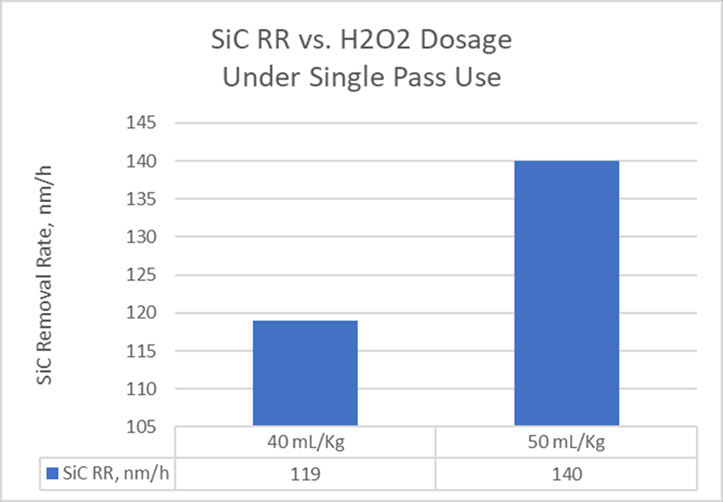

We have two solutions for fine polishing process depended on “single pass use” or “recycle use”. SN12002 was designed for single pass use, and it uses hydrogen peroxide as oxidant.

Figure 6

SN12002 polishing data are showing in figure 6: its SiC removal rate is about 100 nm/h ~ 150 nm/h depended on hydrogen peroxide dosage (40 mL/Kg means add 40 mL hydrogen peroxide per kilogram of SN12002 and H2O2 is 31% w/w solution). Flow rate is 30 mL/min for 32” platen size. Larger platen size needs higher flow rate to make sure the slurry that can spread all over the platen. It needs to note that slurry isn’t stirred during the polishing; otherwise hydrogen peroxide will decompose very fast. According to experimental data, SiC removal rate will drop to 30 nm/h after five hours if keep stirring the slurry. Roughness can be improved to 0.5 Å ~ 0.7 Å after SN12002 polishing and tiny scratches caused by SN12500 can also be removed.

SN12001 also uses hydrogen peroxide as oxidant, and it was designed for recycle use, which means circulate the slurry between polisher and slurry tank during the polishing process with high flow rate (such as 3 L/min). It needs to proceed filtration between slurry out and polisher to remove the debris caused by polishing.

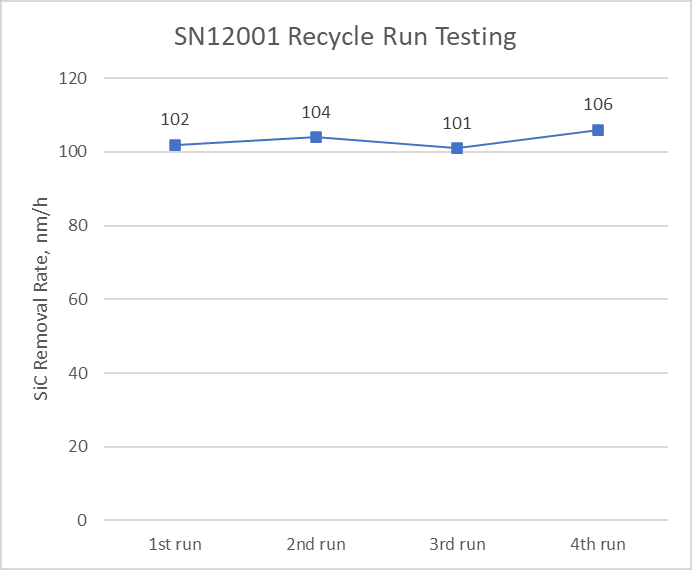

Figure 7

We have tested the recycle runs of SN12001, polishing time is 3 hours for each run, and its average removal rate for each run are showing in figure 7. SN12001 can provide stable removal rate within 4 runs polishing (12 hours totally). Because recycle use adopts high flow rate, it will cause stirring effect while SN12001 back to the slurry tank. The effect leads to the increasing decomposition rate of hydrogen peroxide. Thus, it needs to add hydrogen peroxide every 3 hours. SN12001 also provides good roughness (0.5 ~ 0.7 Å).

Conclusion

SN12500 series provide high throughput with good roughness. SN12001 & SN12002 can further improve roughness to 0.5 Å ~ 0.7 Å and fix the post polishing scratches. GC13020 can remove KMnO4 and MnO2 rapidly even these compounds already dried on the tool, tank, or pad. GC13020 can be used as post cleaner to remove alumina residual and its cleaning efficiency is better than 5% H2O2 solution. Our total solutions can satisfy the requirements of silicon carbide substrate CMP process.

下一篇: 碳化硅化学机械抛光技术最新进展