Abstract: Silicon Carbide (SiC) as the third generation semiconductor material has a very high surface quality requirement, which is the core index in the engineering application. Chemical Mechanical Polishing (CMP) is the only technology that can realize global flattening and non-damage surfaces at present. In this paper the recent advances in traditional CMP, the effects of slurry, and hybrid CMP of SiC were reviewed. The principles and recent developments of CMP were introduced. Then the influence of various factors of slurry on polishing performance was discussed. In addition, recent advances in hybrid CMP technologies, such as Electrochemical Mechanical Polishing (ECMP), Photocatalytic Chemical Mechanical Polishing (PCMP), Plasma Assisted Polishing (PAP), Catalyst-Referred Etching (CARE) were reported, especially some efforts to make these technologies environmentally friendly. Finally, some shortcomings of CMP technology in the application of SiC are summarized and prospect its future development trends.

1. Introduction

Silicon Carbide (SiC) is the third generation of semiconductor ideal material after the first generation of semiconductor Silicon (Si) and the second generation of semiconductor Gallium Arsenide (GaAs). It has the advantages of the wide band gap, high electron breakdown rate, good thermal conductivity, high saturated electron drift rate, and is very suitable for the requirements of high frequency and high power electronic device materials.At the same time, the Mohs hardness of silicon carbide is as high as 9.5, second only to diamond, with high brittleness and stable chemical properties.These characteristics also lead to the difficulty of its processing. At present, more than 250 types of silicon carbide crystals have been found, of which 3C-SiC, 4H-SiC and 6H-SiC silicon carbide are the most widely used, and 4H-SiC and 6H-SiC wafers with a diameter of 8 inches have been successfully commercialized.

As the integrated circuit industry continues to advance and structure size is continuously reduced, the requirements for the surface quality of silicon carbide wafers continue to improve.In the semiconductor industry, the surface quality of the SiC wafer has a significant effect on the quality of the final product. For application, the roughness (Ra) of the substrate is usually required to be below 0.3 nm.The surface flattening technology of silicon carbide materials must be continuously improved to meet the needs of industry development. Typical wafer processing processes include ingot processing, slicing, edging, laser marking, rough grinding, fine grinding, CMP, post-CMP cleaning, inspection, packaging, and other process steps.Chemical-Mechanical Polishing (CMP) is the sole method to obtain global flattening polishing with almost no damage and is the main processing method to obtain high surface quality silicon carbide wafers in industry at present.

Although CMP technology has been widely used in the industrial production of SiC wafers, it still has problems such as low processing efficiency and unclear material removal mechanism.This paper summarizes the principle and classification of chemical-mechanical polishing technology, focusing on the factors that affect the efficiency and precision of CMP and the auxiliary efficiency enhancement technology of chemical-mechanical polishing.

2. Traditional CMP technology

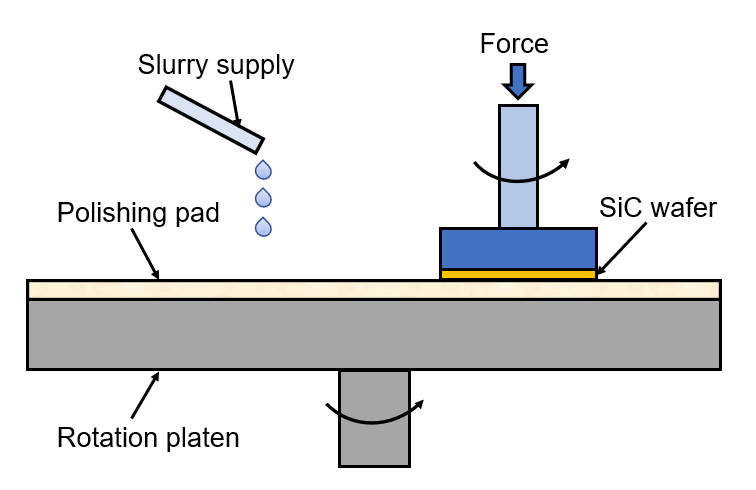

The typical working principle of chemical-mechanical polishing is shown in Figure 1. The polishing head moves relative to the worktable. At the same time, the wafer fixed on the polishing head is pressured with a certain value, which generates a certain relative movement with the polishing pad in the polishing fluid. The material removal process in CMP is a process of chemical reaction and mechanical grinding. First of all, the polishing slurry composed of abrasive particles and a chemical solution is uniformly distributed onto the surface of the polishing pad by the centrifugal force when the workbench rotates at high speed, and a soft SiO2 oxidation layer is formed under the action of the oxidant in the polishing fluid.3 During the process of corrosion and oxidation, oxygen atoms in the medium will be adsorbed on the surface of the substrate, generating oxidation products.Subsequently, the oxidation layer is removed by friction under relative motion between abrasive particles and the wafer to obtain a high-quality wafer surface.

Figure 1. Typical setup of chemical mechanical polishing

3. Influencing factors of CMP slurry

The input variables of the CMP system are numerous, and the state variables are also changing with the continuous processing, and various factors interact with each other, which makes it very difficult to study and control the MRR, the uniformity of surface material removal, and defects. At present, there is no clear and unified theory on the impact of diverse factors on MRR and polishing quality, which needs further study. This chapter will summarize the existing research results in this field.

3.1 Abrasive

In the CMP process of SiC, after the wafer surface is oxidized to form a soft oxidation layer, the surface material is mechanically removed through the interaction between abrasive particles and the machined surface. The diameter of abrasive particles is generally tens of nanometers. Commonly used abrasive particles include SiO2, CeO2, Al2O3, nanodiamond, etc. In addition, polymers and composite materials also have the potential to be used for abrasive particles.

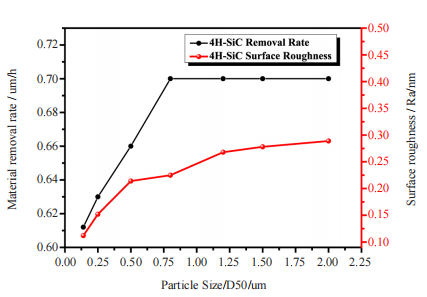

In practice, the abrasive particle size also has a considerable effect on MRR and surface roughness. In 2022, Wang et al.19 studied the impact of different alumina abrasive particle size distribution D50 on 4H-SiC (0001) MRR and surface roughness. The pH adjustment that was applied to regulate the pH value to 9.20 in the test is KOH, and the oxidant was 3 wt% KMnO4. As shown in Figure 2, the MRR increased from 0.61 μm/h to 0.70 μm/h as the particle size D50 increases from 0.1 μm to 0.75 μm. In particular, when the particle size D50 outnumber 0.75 μm, the MRR of SiC was not changing anymore. From Figure 2, it can be seen that the surface roughness increased as the particle size D50 increased from 0.1 μm to 2 μm can be obtained.19 Similarly, in 2022, Zhao et al.20 studied the MRR variation in Mn-based polishing slurry abrasive size with three different abrasive sizes of 0.4 μm, 1 μm and 3 μm. As the polishing abrasive size became larger, the mechanical removal ability was improved. However, the improvement of the MRR of the Mn-based slurry with the abrasive size increases was limited.

Figure 2. 4H-SiC(0001) removal rate and surface roughness as a function of alumina particle size

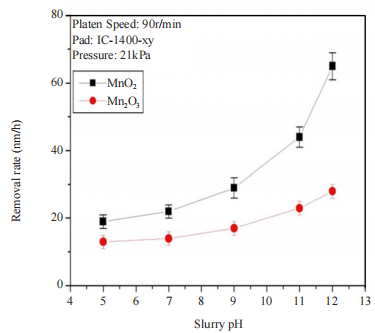

In 2012, Su et al.investigated the change in MRR as the pH value increases between 9 and 13. From the result, the MRR improved as the pH value increased until the pH reached a certain value, and then began to decrease. In particular, the optimum pH values of the C surface and Si surface were different, and the MRR of Si-face was more sensitive to changes in pH value. In 2021, Wang et al. developed a kind of Fe3O4 catalyst, and compared the removal rate in acidic and alkaline environments, which pH values are 2.5 and 9.0 respectively. The result determined that the removal rate in alkaline environment exceeded that in acidic environment by a significant margin.28 Similar result were obtained in experiments on acidic- and alkaline-based colloidal silica slurries in CMP by Aida et al. Likewise, in 2022, Zhao et al. varied the pH values of the MnO2 and Mn2O3 slurries to determine how pH value influences the polishing efficiency of SiC wafer. From Figure 3, the MRR showed an increasing trend when the pH value changed from < 7 (acidic) to >7 (alkaline).20 This trend aligns with the findings reported by Yin et al. in 2018.

Figure 3. Effect of the slurry pH on the MRR of the SiC substrate

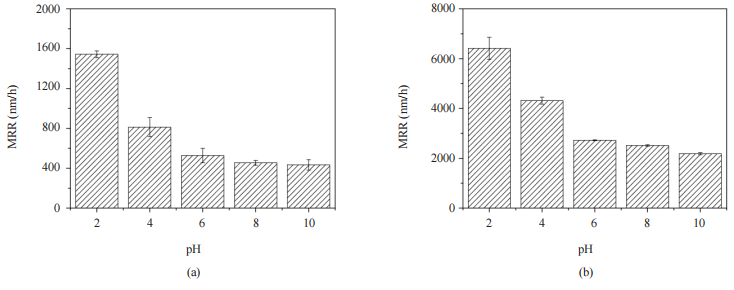

However, some researchers have obtained distinct results in different slurry environments. In 2020, Chen et al.performed CMP on 6H-SiC using a slurry containing a 2 wt% KMnO4 oxidant and alumina nanoparticles abrasive. The pH values of the slurry were controlled by nitric acid or potassium hydroxide to explore their effect. Based on the data presented in Figure 4, it is evident that the MRR of two different surfaces exhibited a significant drop from pH 2 to 6, subsequently, appearing a gradual decline from pH 6 to 10. The highest MRR (1,554 and 6,412 nm/h) was observed on the Si surface and C surface, respectively. The significantly higher MRR observed on the C surface suggests that the MRR was strongly influenced by the surface polarity of the SiC wafer.30 Similar result was gained in 4H-SiC CMP using different pH value slurries composed of 6.5 wt% KMnO4 oxidant and Al2O3 abrasive by Wang et al. In 2021, Wang et al. proposed a novel ultraviolet-TiO2 (UV-TiO2) activation of persulfate and examined the synergistic catalytic effect in enhancing the removal rate in different pH values environments. The results demonstrated that the MRR exhibited an upward trend with increasing pH values within the range of 2 to 6. However, beyond this range, as the pH value continued to rise, the MRR showed a subsequent decrease.

Figure 4. The effect of pH value on the MRR of 6H-SiC substrates: (a) Si-face; (b) C-face

4. Variants of CMP technology

The ultra-high hardness and chemical inertness of SiC contribute to low MRR during the CMP process. Therefore, researchers have developed many auxiliary efficiency technologies based on traditional CMP to achieve higher MRR and improved surface quality. Integrating other forms of energy such as electric energy and light energy into the CMP system can effectively promote oxidation efficiency and MRR. The design of these auxiliary efficiency technologies is also based on this principle, such as Electrochemical Polishing (ECMP), Photocatalytic Chemical Mechanical Polishing (PCMP), Plasma-Assisted Polishing (PAP), Catalyst-Referred Etching (CARE) and other technologies. The principle of these technologies and their latest progress are focused on as follows.

4.1 Electrochemical Mechanical Polishing (ECMP)

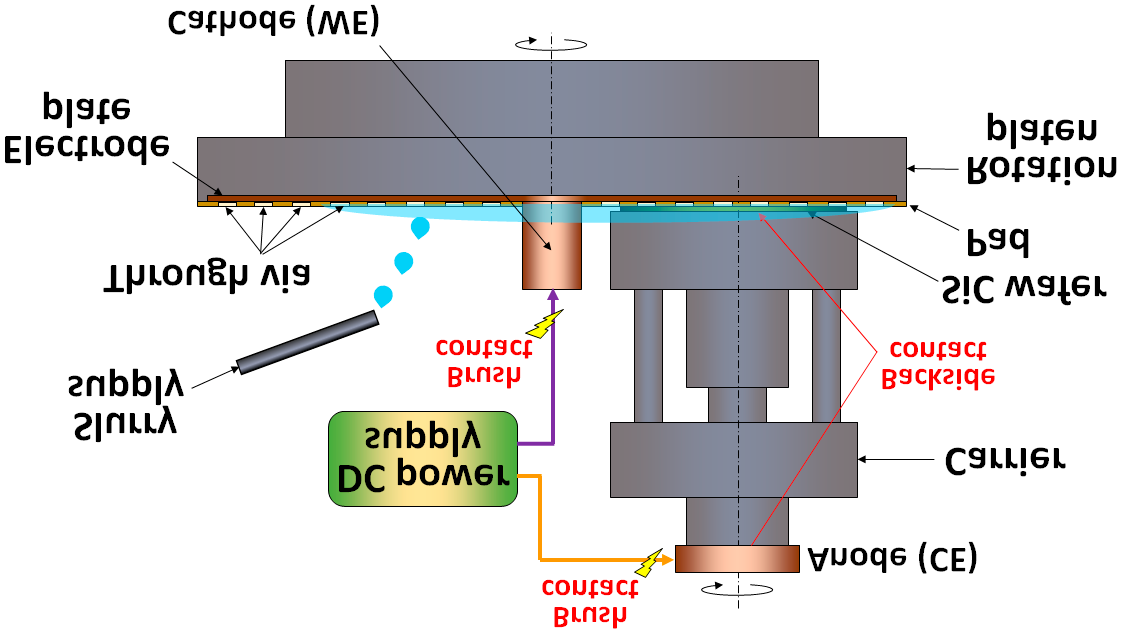

Figure 5 illustrates representative equipment of ECMP. Different from traditional CMP, ECMP uses electrolytes as the polishing slurry. In the polishing process, the SiC surface serves as the anode, leading to the formation of an oxide layer with lower hardness because of the applied charge. Subsequently, this softer surface is mechanically eliminated through the use of soft abrasives. Because of the lower hardness of the soft abrasives, the Subsurface Damage (SSD) is not introduced when the surface oxide is removed, making a damage-free surface possible.

Figure 5. Typical equipment for SiC ECMP

5.Conclusions and prospect

The research status of the CMP of SiC is summarized in this paper. Firstly, the principle and developments of the traditional CMP technology are summarized. Then the influence of the abrasive particles and oxidants of polishing slurry on machining is discussed. High-quality and efficient polishing fluid is the goal pursued by researchers. The influence of different kinds of abrasives and oxidants on the MRR and surface quality of silicon carbide CMP material is also the main research direction at present. The balance between the polishing quality, the polishing efficiency and polishing cost is the core issue in the research process. After that, the advantages and disadvantages of various CMP variants developed from the traditional CMP technology and their respective development were discussed. The characteristics and performance parameters of different CMP technologies are compared in Table 1. These technologies play a significant role in solving the problem of low efficiency of SiC processing, and more in-depth research on them is also a hot spot, especially some more environmentally friendly improvement methods. Surface quality and processing speed are two most important requirements in SiC processing. Although SiC has been widely used, the processing technology still needs to be developed.

上一篇: 碳化硅基板抛光整体解决方案

下一篇: 碳化硅的新型光子应用