Abstract

Lithography-based additive manufacturing methods emerged as a powerful method for manufacturing of complex-shaped ceramic parts with excellent functional and structural properties. This paper summarizes the current state of the art in this feld by articulating technological challenges associated with printing of functional parts. In addition, the paper addresses process requirements towards further enhancing component quality. A key aspect for obtaining high-quality parts is related to controlling chemical composition and uniformity of the photopolymerizable slurries. The latter requires in-depth understanding of the underlying photochemical processes. Changes in the formulation of the resin as well as changes in the exposure strategy distinctly infuence bond conversion and gelling, which, in turn, infuence the properties of the green part during thermal processing. Properly optimized processes and material composition allow to target a variety of challenging applications including patient specifc parts for digital dentistry, and 3D-printed ceramics which can operate in harsh environments, as may be required in aerospace or chemical engineering applications. The paper will also provide an outlook into novel opportunities for 3D-printed ceramics.

Introduction

Ceramic materials ofer a wide range of benefts: they provide high stifness and strength at comparably low weight, they are corrosion resistant and mostly biocompatible, and their functional properties (thermal and electrical conductivity, optical properties, …) can be tuned over a large range. Typical felds of application include biomedical engineering (dentistry, orthopedics, …), aerospace and energy, and electronics. For many applications small, yet complexly shaped parts are needed, making additive manufacturing (AM) a suitable choice for manufacturing.

Materials and methods Systems and processes

Several types of systems for lithography-based ceramic 3D-printing have been proposed. What they all have in common is their (1) layer-wise approach for defning shapes of virtually arbitrary part complexity and a (2) light-engine which allows the selective exposure of photopolymerizable slurries. The slurry can either be exposed either in a raster-based or in a vector-based fashion.

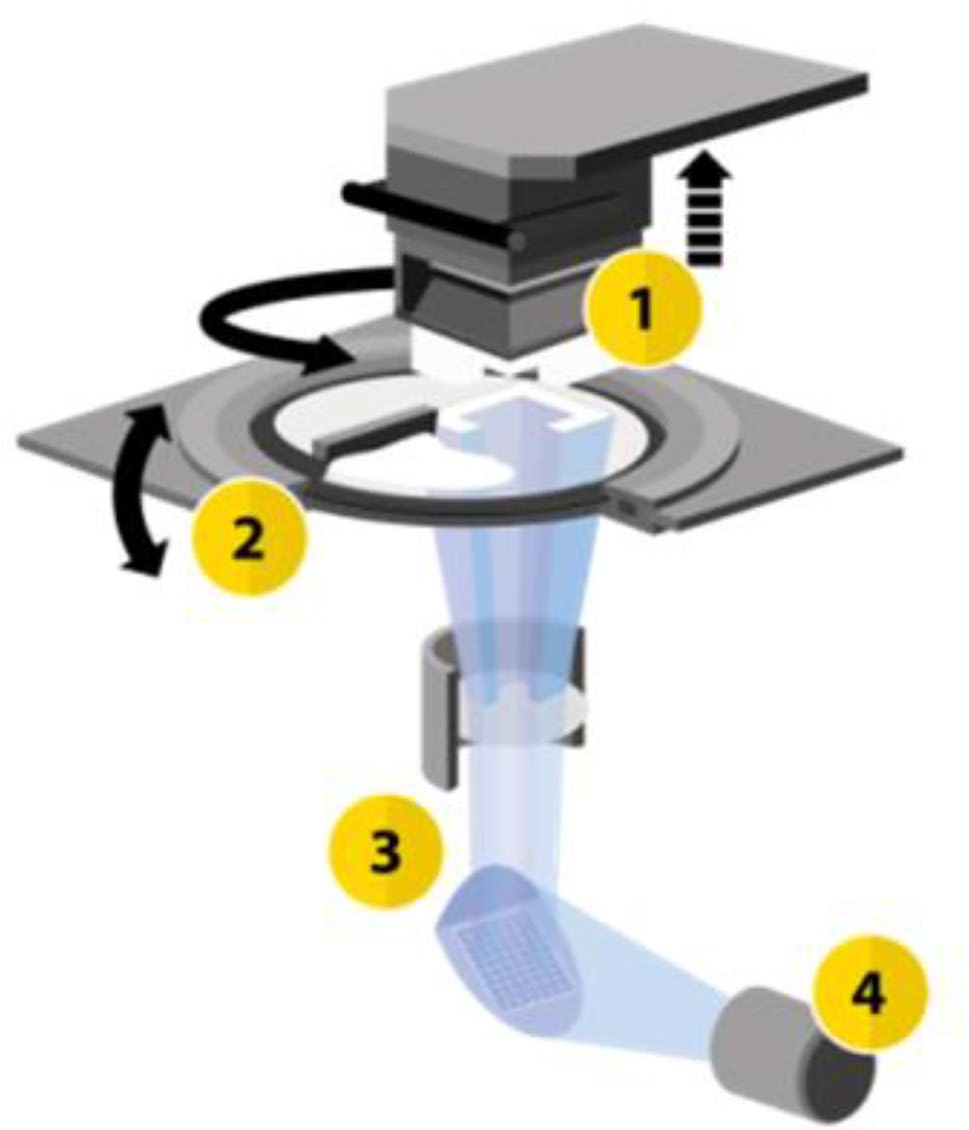

Since the density of the inorganic fllers is typically much higher than the density of photopolymerizable organic formulation, measures for preventing sedimentation of the ceramic particles must be taken. On one side, proper dispersion of the particles is necessary. Additionally, continuous agitation of the slurry is helpful to avoid sedimentation. Above-mentioned rotating vat is very helpful in this context. In Fig. 1 the principle setup of a modern ceramic 3D-printer is sketched.

Figure 1. Schematic scheme of a lithography-based ceramic 3D-printer. 1 building platform, 2 vat, 3 optical system with DMD, 4 light source (LED).

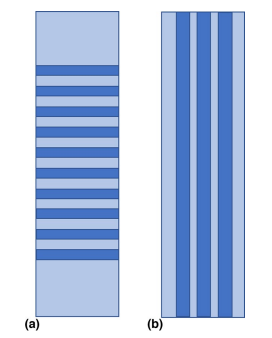

Above presented theoretical considerations are in good accordance with experimental evidence. When using CNCmachined molds in combination with gelcasting slurries, 4-point bending beams with defned surface roughness can be obtained. By utilizing diferent machining paths, molds with scalloped machining grooves parallel to the long axis of the beam can be prepared [Fig. 2(b)], as well as molds with perpendicular scallops. Parallel scallops, being in the same direction as the stresses acting on the 4-point-bending beam, should have no infuence on the strength of the material. In contrast, perpendicularly scalloped surfaces [Fig. 2(a)] serve as notches and potentially reduce the strength, depending on their depth.

Figure 2. Perpendicular (a) and parallel machining grooves on 3-point bending beams.

Slurry formulation

When formulating ceramic flled slurries suitable for stereolithography, the organic matrix, the type of ceramic fller and the interaction between fller and matrix need to be considered. The ceramic slurries need to contain rather high amounts of ceramic powder of>45 vol% in order to ensure proper densifcation upon sintering. The photocurable organic matrix is a tailored system for each used grade of ceramic powder. These binders are based on a low viscous solvent, reactive monomers of diferent functionality based on acrylate and methacrylate chemistry, a photoinitiator that is active at the emitted wavelength of the LEDs at a low amount of less than 1 wt%, and process specifc additives such as dispersants to properly homogenize and stabilize the suspension a s well as dyes to moderate the light penetration.

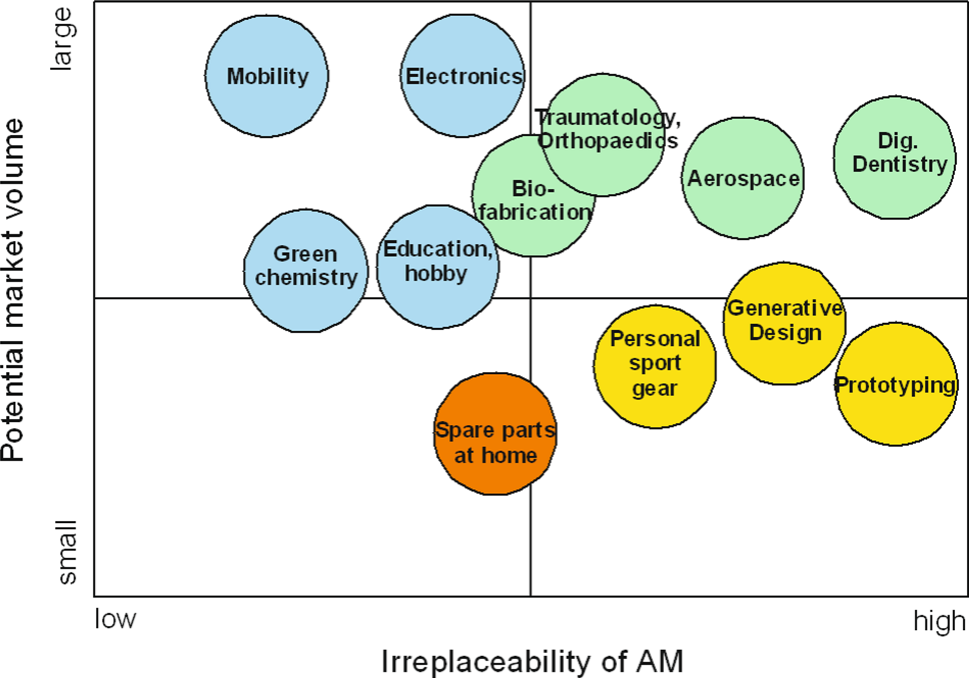

As indicated in Fig. 3, felds like electronics and electrochemistry (batteries and fuel cells) ofer large potential for 3D-printed ceramics. Lithography is a well-established technology in micro-electronics, and the demand for future miniaturization and further integration plays into the hands of lithography-based 3D-printing of ceramics. The latter provides for necessary resolution, needed structural properties, as well as electrical and thermal properties, including electronic and ionic conductivity. Other relevant material properties as such as coefcient of thermal expansion and chemical and thermal stability are also achievable with 3D-printed ceramics. Applications such as complexly shaped ceramic separators or heat thinks with conformal cooling channels might open inroads into large and growing markets. In terms of potential market size, microelectronics with its large global market size of 440 Bill. US$ in 2020 will increasingly ofer very interesting use-cases for 3D-printed ceramic parts (e.g., electrical connectors, interconnects, 3D-printed functional ceramic parts for sensors, …).

Figure 3. Qualitative estimation of the potential market volume over irreplaceability of 3D-printed parts in various felds of application.

上一篇: 半导体金属氧化物传感器路线图:回顾

下一篇: 石墨烯的性质、合成和应用:综述