Abstract— Shrunken patterning for integrated device manufacturing requires surface cleanliness and surface smoothness in wet chemical processing. It is necessary to control all process parameters perfectly especially for the common cleaning technique RCA clean (SC-1 and SC-2). In this paper the characteristic and effect of surface preparation parameters are discussed. The properties of RCA wet chemical processing in silicon technology is based on processing time, temperature, concentration and megasonic power of SC-1 and QDR. An improvement of wafer surface preparation by the enhanced variables of the wet cleaning chemical process is proposed.

I. INTRODUCTION

THE SC-1 (APM) and SC-2 (HPM) standard clean or RCA, as published in Kern in 1970 have been the primary means of removing particles. In order to optimize the cleaning recipe to meet the cleanliness requirements of advanced CMOS device with the available chemicals, the details of the APM and HPM chemistries are being reevaluated. To this end, the effects of processing time, temperature, concentrations and megasonic power of SC-1 and QDR are extensively studied. These studies have shown that the largest main effect for particle removal efficiency is megasonic power, followed by temperature and concentration with small effect from SC-2. A statistically designed experiment (DOE) was conducted in a wet bench processor. This paper is going to propose a wafer surface preparation RCA recipe having optimal particle removal efficiency, based on proper megasonic power for SC-1 and QDR and SC-1 temperature. Further, each result will be discussed in detail.

II. EXPERIMENT

A total of 16 runs were made and the run order as given in TABLE 1 and TABLE 2 was randomized. All processes were conducted in a fully automatic DNS wet station on 200mm, cz, p-type, 7-10: wafers from SEH. The chemical tanks are recirculated and filtered. The SC-1 and QDR bath are equipped with megasonic.

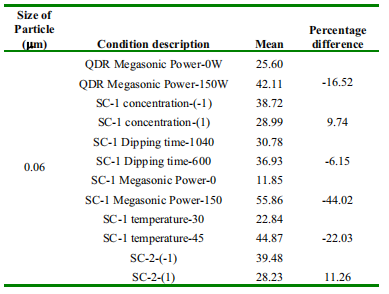

TABLE 1 SUMMURY RESULT OF DESIGN OF EXPERIMENT FOR 0.06 P M PARTICLE SIZE

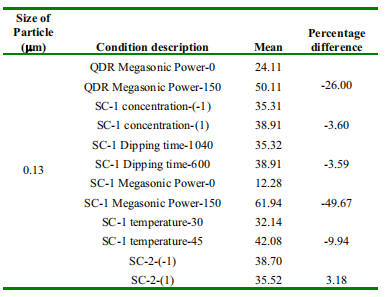

TABLE 2 SUMMURY RESULT OF DESIGN OF EXPERIMENT FOR 0.13 P M PARTICLE SIZE

The wafers are intentionally pre contaminated by processing the wafers in HF bath and in a resist tool type with spin to dry dryer. HF will change the wafer surface to hydrophobic, which repels water, and easily attract particles. Typical contamination is varied from 100 – 2000 particles with particle threshold at 0.13 and 0.16 Pm. As PRE is strongly dependent on initial counts and on the initial conditioning of wafers (cleaning before contamination), the wafers are randomly selected for each DOE condition [3]. All experiment on contaminated wafers was carried out on samples from the same batch.

Three wafers are used for slot 1, 25 and 50 with dummy oxide coated and etched wafers slotted in between to simulate the actual production condition and provide challenging contamination level because dummy wafers contained etch by-products that could transfer to bare Si wafers. Pre and post scan data are taken using SP1, a laser based particle counter to detect the particle levels. The SP1 produces a haze map. Haze is the low frequency signal caused by the scattering of laser light during darkfield inspection and can reflect minute variations in surface uniformity or roughness that are caused by wafer processing. The data will be further analyzed with variability graphs using JMP software to determine the significant factor in particle removal efficiency.

III. RESULT

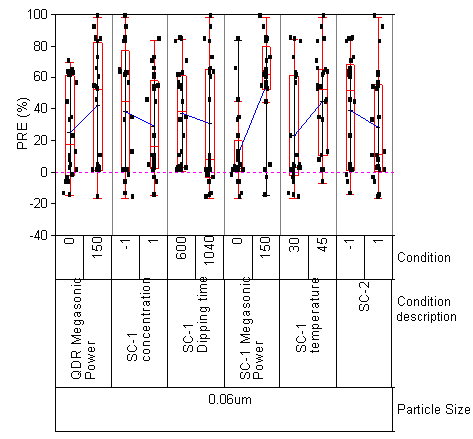

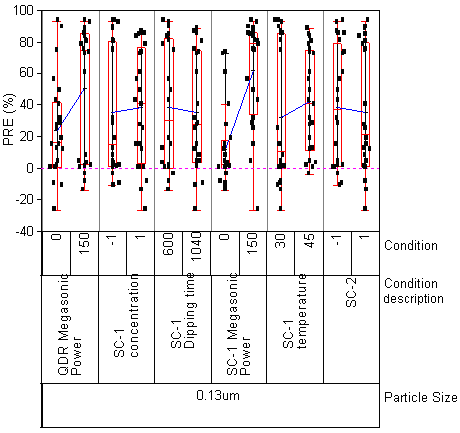

The rise of temperature for SC-1 from 30 to 45 results in PRE improvement especially for 0.06um particle size. This phenomenon are shown graphically in Fig. 1 and Fig. 2, where PRE% is seen to increase noticeably with increasing temperature. High temperature helps in removal of most particles by etching the wafer surface and the particles to some extent, thus reducing the particle adhesion forces with the wafer and promoting particle movement away from the wafer and into the bulk of the solution. PRE% is higher for small particles as compared to big particles as the surface contact of small particles is higher than big particles, therefore the forces which holding the particles onto the surface is higher. By increasing the temperature, the PRE% for smaller is seen to change rapidly.

Fig. 1 Variability chart for PRE with different RCA condition for 0.06P m particle size

Fig. 2 Variability chart for PRE with different RCA condition for 0.13 Pm particle size

The result indicates that condition with skip SC-2 has higher particle removal efficiency for 0.06um particle and above as compared to process with SC-2. As for 0.13um particle and above, the particle removal efficiency do not show significant different. The zeta potential between the particle and substrate increases when the pH for the solutions decreases. Therefore for condition with SC-2 process, particle re-deposition in the acid chemical will reduce the particle removal efficiency. SC-2 cleaning after SC-1 cleaning is not a desirable process sequence. But, SC-2 chemical is useful for removing metal contamination generated in etch equipment during the etch process. Skipping SC-2 cleaning is desirable in the process which metal contamination has no impact on.

IV. CONCLUSION

Excellent PRE was attained with megasonic energy mainly with SC-1 chemistry. Megasonic energy along with chemistry dilution helps to remove particles without increasing surface roughness. Acoustic energy can be used to balance the low concentration and shorter processing time of SC-1 chemistry. Based on statistically designed experiments, SC-1 temperature has been observed in these experiments to be the second dominant factor for particle removal using SC-1 type chemistry. Bath temperature also helps to modify the effect of power on particle removal with diluted and short processing time of SC-1. Eliminating SC-2 process also improves in PRE. This dramatically reduces the consumption of chemicals while providing the advanced process results needed for next generation of integrated devices. The major accomplishment of this development is optimizing PRE with dilution of SC-1 with higher temperature, short immersion time and with appropriate megasonic power. The use of substantially diluted chemistries has significant cost saving ramification for semiconductor manufacturers. The reduced chemical usage also reduces wastewater treatment requirements, resulting in an environmentally conscious mode of manufacturing.