Abstract

The properties of a commercial indium-tin-oxide (ITO) layer deposited on glass substrates were evaluated as a function of the treatment time in diluted aqua regia solution. The samples were characterized by atomic force microscopy (AFM), bulk conductivity, ellipsometry, energy-dispersive X-ray analysis (EDX), contact angle/surface energy, and work function measurements. The results show that shorter times of treatment do not affect significantly the ITO properties but decrease the ITO thickness. For longer times (more than 30 min), although the work function and In/Sn ratio are not affected by the treatment, conductivity, roughness, UV–VIS absorption spectra, and refraction index values are greatly affected. Contact angle and surface energy data indicated that the dispersive component of the surface energy was not affected by the treatments. However, a strong decrease in the polar contribution occurred, indicating that ITO surface becomes more hydrophobic as the chemical treatment proceeds. These treated surfaces can interact more strongly with nonpolar materials, such as poly-( p-phenylene-vinylene) derivatives, resulting in a strong polymer ITO adhesion that can improve the efficiency of polymer light-emitting diodes (PLEDs).

1. Introduction

Indium-tin-oxide (ITO) has been traditionally used as antireflection coatings, conductive and transparent heating elements in aircraft windows, and in several devices of modern electronic technology, including liquid crystals flat panel displays, and polymer light-emitting diodes (PLEDs) . ITO has been by far the common choice as transparent electrode on PLEDs due not only to its availability but also to its lower resistivity, good transparency, and ease of patterning. In addition, ITO may be used as a hole transport layer for poly( p-phenylene-vinylene) and its derivatives. However, recent developments of PLEDs have demonstrated that the optical and chemical properties of ITO need to be controlled more accurately to improve device performance . These properties depend on various ITO deposition conditions, chemical surface treatments, cleaning, and etching processes. The control of roughness, work function, thickness, and electrical conductivity of ITO, among other parameters, are essential for improving device performance. The adhesion between the polymer and ITO can also be affected by the chemical treatments since it may change the hydrophobic character of the oxide, thus increasing the contact area at the ITO-polymer interface.

2. Experimental

2.1. Samples characterization

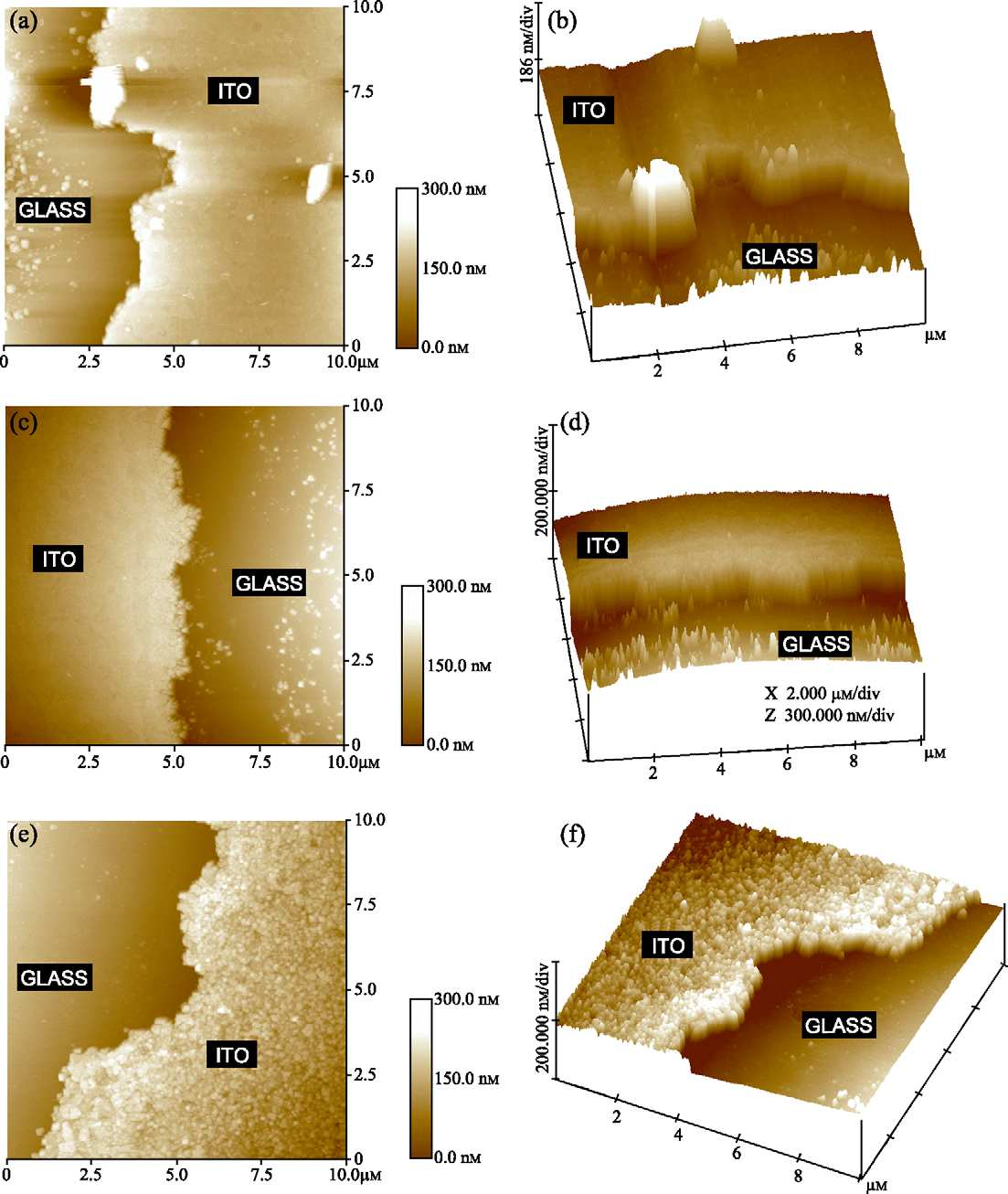

2.1.1. Atomic force microscopy (AFM) Images were recorded in a Multimode NanoScope III Digital Instruments in the contact mode to investigate surface morphology of the samples. The ITO layer thickness was measured by scanning a large area (10x10 Am) where both the nonetched and etched areas were present and the edges of the nonetched area (ITO edges) could be clearly visualized. The thickness (l) of the ITO layer was determined measuring the height of ITO layer to the glass surface. The ITO layer roughness was estimated using the software Nanoscope III as mean quadratic roughness (Rms).

2.1.2. Electrical properties

The sheet resistance (R) was measured using the fourpoint probe technique, applying a current from a constant current source (Keithley 224) and measuring the voltages between the two inner probes with an electrometer (Keithley 617). The correction factor value of 4.53 was used. From R and the ITO thickness (l), the bulk conductivity of the samples was obtained using r = (RX l) -1 . The work function was measured by the Kelvin probe technique using a fine evaporated gold film (100 nm) as reference.

3. Results and discussion

Fig. 1 shows AFM bi- and three-dimensional images of ITO surfaces untreated and treated in diluted aqua regia for 15 and 60 min. The surface morphology of aqua regiatreated ITO is significantly changed, especially for the sample treated during 60 min. The columnar formations that appear in the untreated sample tend to disappear with the aqua regia treatment. Also the edges of the patterning can be clearly visualized, being quite sharp and no residues of the adhesive tape could be noticed. The roughness and thickness values obtained are presented in Table 1. Roughness increases moderately with aqua regia treatment until 30 min, followed by a pronounced increase. Similar results were obtained by Kim et al., also using dilute aqua regia, but in an ultrasound bath. Mean roughness varied from 2.6 (0 time) to 8.4 nm after 15 min of treatment. The thickness decreased with the time of treatment, the decrease being more pronounced in the initial period of treatment. Table 1 also shows the values for sheet resistance, conductivity, ratio of Indium (In), and Tin (Sn) surface contents determined by EDX and the work functions (WF) obtained. The sheet resistance increases with the time of treatment, in a more accentuated manner after 30 min. The sheet resistance values of the ITO used in this work are lower than that measured by Kim et al. (around 16 V/Sq). The conductivity increases slightly until 15–20 min of treatment and decreases to almost the half of the initial value after 60 min. The In/Sn ratio measured by EDX of the ITO surfaces is almost unaffected by the treatment in aqua regia, regardless of the time, indicating that both oxides (SnO2 and In2O3) are removed in the treatment in similar amounts. EDX analysis did not show the presence of zinc in the ITO surface, even near the edges. In addition, the patterning procedure did not leave Sn, In, or Zn residues.

Fig. 1. AFM images of ITO substrates treated in aqua regia: (a and b) untreated samples, (c and d) 15 min treated, and (e and f) 60 min.

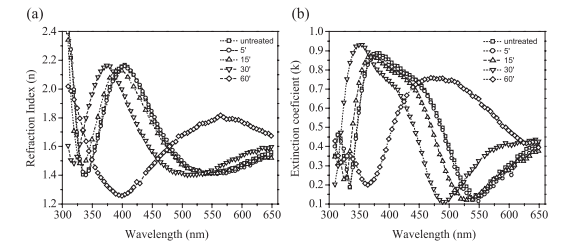

Fig. 2a and b shows the refraction index (n) and the extinction coefficient (k) for ITO in the wavelength range from 300 to 650 nm, measured by ellipsometry, and using the thickness value obtained by AFM. The refraction index curves of the untreated and of the treated samples with shorter times (until 15 min) are very similar, showing a maximum value around 400 nm. The sample treated for 30 min showed a slight shift to shorter wavelengths with values of maximum refraction index similar to the untreated sample. However, the sample treated for a longer time (60 min) showed a large shift to longer wavelengths and lower values of maximum refraction index, indicating that severe changes have occurred during this particular treatment. The same observations apply to the extinction coefficient curves. The samples untreated and treated for 5 and 15 min presented maximum absorption around 370 nm, the sample treated for 30 min with the maximum at a wavelength ca. 20nm shorter. The sample treated for 60 min presented a larger absorption with maximum between 400 and 500 nm. This large absorption makes this treated ITO unsuitable for some display applications, as the materials used in such applications emit visible light that will be absorbed—at least partially—by ITO.

Fig. 2. Ellipsometry results for untreated and aqua-regia-treated samples. (a) Refraction index curves; (b) extinction coefficients curves.

4. Conclusions

The patterning process in aqua regia produced well defined and clean edges between the etched and nonetched surface that permitted the measurements of ITO thickness easily. The chemical treatment with shorter times does not affect significantly the ITO properties, only decreasing its thickness. For longer times (more than 30 min), although the work function and In/Sn ratio are not affected, conductivity, roughness, and the absorption spectra and refraction index are greatly affected. Contact angle and surface energy data indicated that the dispersive component of the surface energy was not affected by the treatments. However, a strong decrease in the polar contribution occurred as a function of the time of aqua regia treatment, indicating that the surface becomes more hydrophobic. These treated surfaces can interact more strongly with nonpolar materials, such as poly-( p-phenylene-vinylene) derivatives, resulting in a strong adhesion between polymer-ITO. The aqua regia treatment up to 15 min showed to be efficient in increasing possible adhesion without affecting negatively the other ITO characteristics.