Abstract.

This paper study the effective of the HF: ethanol diverse concentrations on the porous silicon properties which calculated using porous silicon contagious of p-type and n-type bulk silicon and using the HF acid of (39-43%) with assisted ethanol the etching time (10) min and voltage (10) volt together electro chemical etching method for bulk p-type silicon and photo electro chemical etching for bulk n-type silicon the porosity of porous silicon can be study "with" Graph metric method and study the comparison between SEM of bulk n-type and bulk p-type for produced psi .

INTRODUCTION

The technology of nano is engineering of substance at require of atomic scale. The vintage law of physics or chemistry it does not apply easily at this too small scale for more than one reasons. the electronic properties in small grains designs can be very different from their larger design in the addition to that the surface ratio of area to volume becomes much higher and since the surface atoms are generally the most interactive, the properties of substance change in un expected methods.

The physical and chemical properties of porous silicon are substantially specific determined through the dimensions of the pores, the thickness of the porous silicon layer and relative content of Si, blanks, and together some cases, the porous silicon relative content of different (Si)compounds in the created porous layer. The parameters which effective in porous silicon preparation depend on the preparation conditions for that it is possible to produce this materials with physical and chemical properties of those between (Si) and air (other medium which fills the pores).In the other side , when size of (Si) structure is less for a few nano meters, different quantum effects make porous silicon even more face more applications because of the properties of porous silicon which make that .

EXPERIMENTAL PROCEDURE

In this content includes describing of all instruments and devices that have been used in the preparation of (Psi) layers as well as the technicality, which have been utilized to study and illustration the property of porous silicon layer. In this study the porous silicon is prepared from bulk p-type for produced porous silicon was bring by use electro- chemical etch (110)/ P-type, size :(125×0.5) mm, and R=1-10 .cm standard-GB. and photo- electro chemical etch for bulk n-type silicon) 110) /directed silicon wafer, standard GB; and R=1-10 .cm

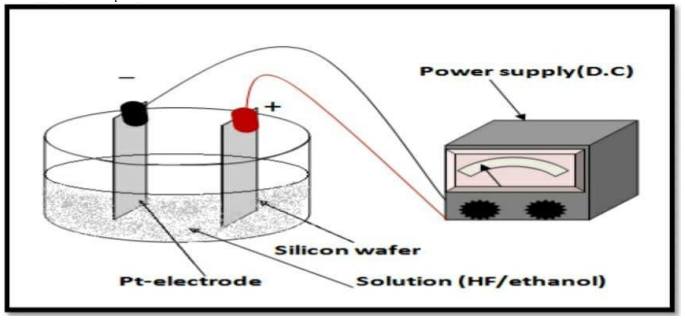

The silicon wafer was divided in to small slice (1.3× 1.5) cm .to clean the slices and remove any dirt from the surface, this slices rinsed with ethanol in dilute (10%) HF this causes removal the origin oxide layer, by using system which can be shown in figure (1) to prepare porous silicon together photo electro chemical etch by using bulk n-type silicon and electro-chemical etching for bulk p-type silicon with etching time (10 min) (1:1),(1:2),(1:3),(1:4),(1:5) different (HF) concentrations and ethanol with assisted light for n-type after (10min) for etching time the sample are dealing for deionized water and leave to dry, after a few minutes it is stocked in a vessel contains ethanol to block from oxidation layer on the piece surface .the photo electro chemical etch is occur under the rooms temperature.

FIGURE 1. A schematic diagram of the electrochemical etching system

SEM Measurements

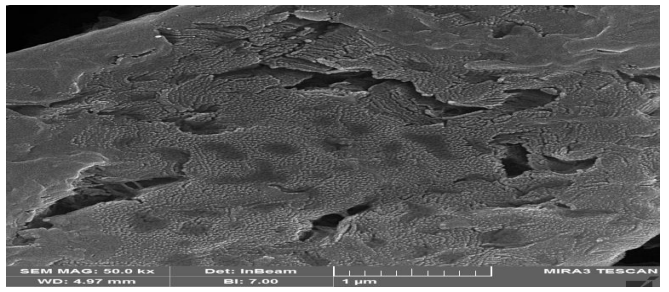

The structure of porous silicon can be directly imaging using (SEM) Microscopy .The topography properties such as pores form of walls inter the pores of the layers (psi) are study using (SEM).

RESULTS AND DISCUSSION

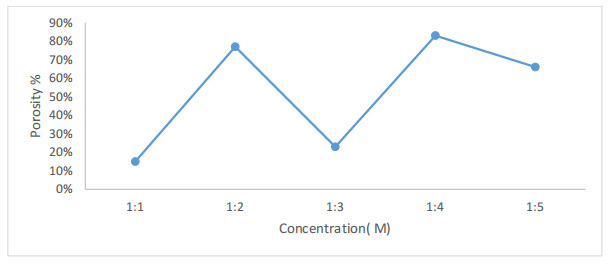

The relation among pporosity porous silicon and different focus in to acid through making specimen may be displayed in figure (2) these vicissitudes come from the Bulk N-type silicon demeanor due this type requires with light while prepare the porous silicon. The porosity is increase with increasing layer thickness and with decrease concentration because the lower concentration the polishing will take place and the better porous layer will be formed and the density increases, due to huge number of voids in the psi layer. And the porosity is decrease with decrease layer thickness and with increase concentration because the high concentration ,a poor porous layer is formed the density decreases it does not polish, resulting in a small number of voids in porous silicon layers.

FIGURE 2. The porosity as a function of concentration for N-type

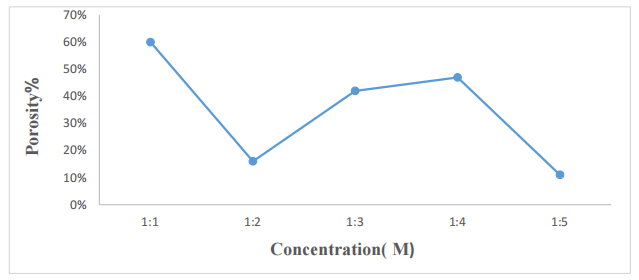

Figure (3) it shows the porosity as a job of acid a focus for hydrofluoric to ethanol, this figure for P-type, one could facilely and differ show in figure (2) the porosity increase together increase concentration because of the high resistance it will get polishing and decrease concentration the porosity is decrease because low the layer thickness it does not polishing ,resulting in a small number of voids in the porous silicon layers.

FIGURE 3. The porosity as a function of concentration for P-type

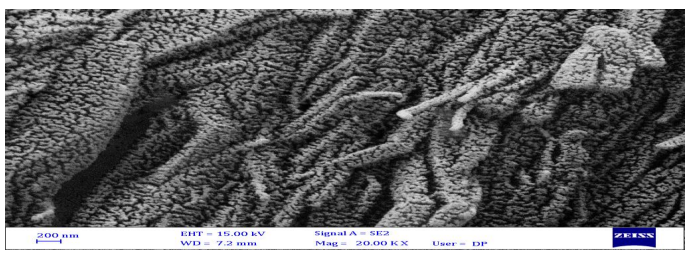

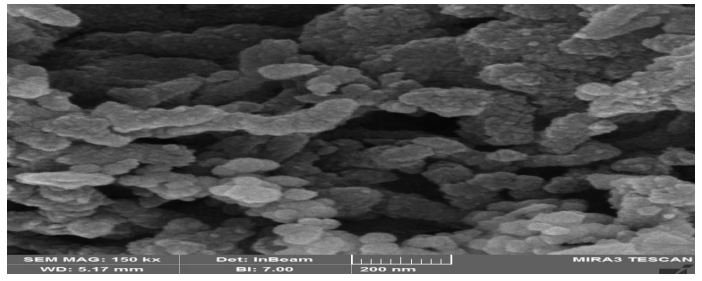

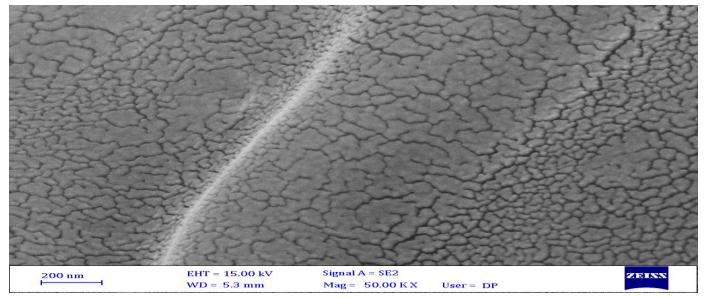

Figure (4) and (5) show SEM for samples with concentrations HF to ethanol (1:1),(1:3) for bulk N-type silicon ,one can see in obviously the pore in the layer of porous silicon and forming very small size gauge silicon , the initially may be seen in Figure (5)[15]. this low concentration might cause change in energy level it reveals the existence of like a ditch structure in different shapes and sizes due to the overlap of large pores, formation of a great density inter the acid and bulk silicon whose leads immediately to giving a space interaction the charge inter and make the polish and gradual take off layer of porous silicon but from figure (4) the porous silicon layer is low because high concentration little porous silicon layer is formed and get a little polishing One can ability see the nano size walls and pores like cavities, whose gave nano properties in these layer. Scanning electron microscopy for porous silicon production from bulk P-type silicon with HF to ethanol (1:1), (1:3) concentrations, it may be seen in Figures (6) and Figure (7). This figure, one can recognize the porous silicon speciality in Figure (6). which can see pores and cavities in that case it will not polish and will not lift the porous silicon layer as in the previous case in the N-type but the low concentration increases the thickness of the layer as in the form of number (7) it appears in the form of many cracks .through this there are many applications can be conclusion from this cases because the conformation it makes many properties characteristics to the porous silicon layer with direct effect to the application it can be found from this porous silicon.

FIGURE 4. SEM image for porous silicon of layer with concentration (1:1) HF: ethanol for silicon N-type

FIGURE 5. SEM image for porous silicon of layer with concentration (1:3) HF: ethanol for silicon N-type

FIGURE 6. SEM image for porous silicon of layer with concentration (1:1) HF: ethanol for silicon P-type.

FIGURE 7. SEM image for porous silicon of layer with concentration (1:3) HF: ethanol for silicon P-type.

下一篇: 金属辅助化学蚀刻对硅光电导体的化学激发