Abstract

Elucidating the complex interactions between the work material and abrasives during grinding of gallium nitride (GaN) single crystals is an active and challenging research area. In this study, molecular dynamics simulations were performed on double-grits interacted grinding of GaN crystals; and the grinding force, coefficient of friction, stress distribution, plastic damage behaviors, and abrasive damage were systematically investigated. The results demonstrated that the interacted distance in both radial and transverse directions achieved better grinding quality than that in only one direction. The grinding force, grinding induced stress, subsurface damage depth, and abrasive wear increase as the transverse interacted distance increases. However, there was no clear correlation between the interaction distance and the number of atoms in the phase transition and dislocation length. Appropriate interacted distances between abrasives can decrease grinding force, coefficient of friction, grinding induced stress, subsurface damage depth, and abrasive wear during the grinding process. The results of grinding tests combined with cross-sectional transmission electron micrographs validated the simulated damage results, i.e. amorphous atoms, high-pressure phase transition, dislocations, stacking faults, and lattice distortions. The results of this study will deepen our understanding of damage accumulation and material removal resulting from coupling between abrasives during grinding and can be used to develop a feasible approach to the wheel design of ordered abrasives.

1. Introduction

The gallium nitride (GaN) single crystal is the semiconductor with the highest application potential for manufacturing chip wafers due to the large bandwidth, high breakdown voltage, high electron mobility, and stable chemical and physical properties under extreme conditions. To fabricate thin chip wafers, bulk GaN crystals must be processed using a sequence of machining methods, including wire saw cutting, grinding, lapping, and polishing. Large chip wafers cannot be machined by lapping and are mainly machined by wire saw cutting, self-rotating grinding, and polishing. Self-rotating grinding can achieve the highest material removal and accurately control the surface shape and thickness of wafers. Self-rotating grinding has thus become necessary for backthinning of chip wafers. However, brittle fractures or micro cracks induced during grinding process can severely deteriorate the application accuracy and service life of crystal components. Therefore, numerous researchers focused on conducting polishing and high-energy beam etching of GaN semiconductors to eliminate the brittle damages of components. Kubota and Iwakiri carried out a tribochemical reaction to polish GaN substrates, producing a smooth surface with a root-mean-square roughness of 0.133 nm. The tribochemical reaction produced an oxide layer on the substrate surface, enabling removal of the work material under low stress. Pan et al performed chemical–mechanical polishing (CMP) tests on GaN semiconductors in conjunction with the electro-Fenton process to promote material removal. Zhang et al polished GaN wafers using plasma and electrochemical etching. The wafer surface had subnanometer-scale roughness, and materials were removed at the atomic scale. Although plastic surface free of surface and subsurface cracks was achieved using CMP or high-energy beam etching technologies, the low material removal efficiency of polishing and etching has hindered the large-scale industrial production and application of GaN chips.

Material removal of semiconductors by grinding occurs largely through mechanical action and to a small extent through the tribochemical reaction. Therefore, the ductile grinding mechanism, i.e. the characteristics of ductile deformation and removal of work materials during grinding, needs to be elucidated to optimize process parameters to achieve highefficiency and high surface integrity machining of hard and brittle materials. Tao et al carried out scratching tests and transmission electron microscopy (TEM) to elucidate the mechanism of ductile damage in silicon wafers. This mechanism was found to facilitate high-efficiency production of high-efficiency production of large-size silicon wafers. Li et al revealed the ductile grinding mechanism of silicon substrates using single-grit scratching tests and smoothedparticle-hydrodynamics simulations, and they concluded that the understanding of ductile mechanism would provide theoretical guidance for optimizing grinding parameters. Wang et al used single-grit impact scratching tests to explore the ductile grinding mechanism of β-Ga2O3. This mechanism was found to facilitate high-efficiency grinding of brittle materials. Single-grit scratch tests were performed in conjunction with cross-sectional TEM to investigate the plastic deformation of monocrystalline GaN induced during grinding. The main forms of plastic deformation were a high-pressure phase transition, an amorphous transition, stacking faults, dislocations, nanocrystals, and lattice distortions . However, as a result of the random distribution of abrasives and complex interactions between the work material and abrasives, the effect of coupling between randomly located abrasives on damage accumulation and material removal during grinding of GaN single crystals remains unclear.

2. Simulation and experimental conditions

2.1. Simulation conditions

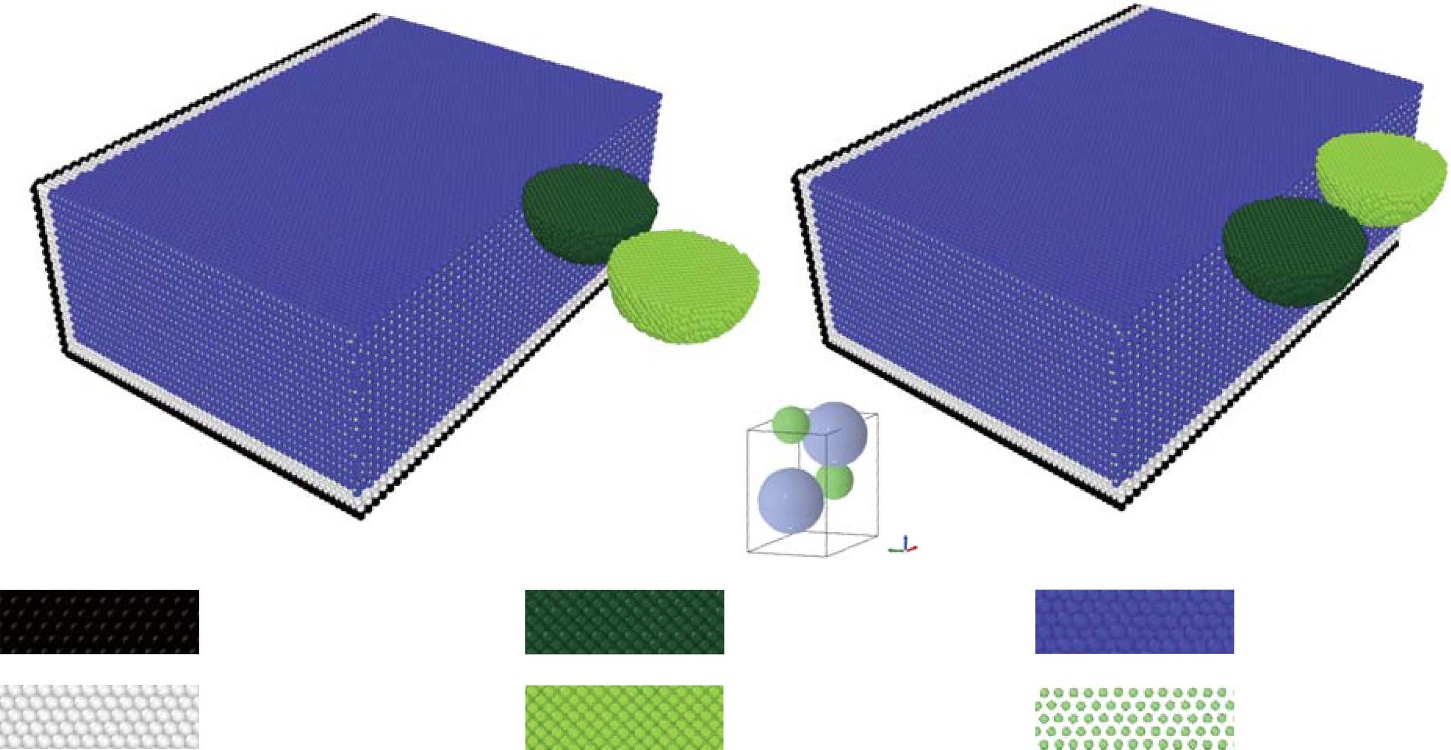

Two kinds of MD models for double-grits interacted grinding of GaN crystals were established using LAMMPS software. Both models consisted of a workpiece with a dimensions of 27.5 nm × 20 nm × 10 nm and two hemispherical abrasives with a radius of 3 nm. Three kinds of atoms were used in both the abrasive and workpiece models, namely, boundary, thermostat, and Newtonian atoms. The atomic positions in the boundary layer were fixed to prevent the workpiece from translating under the action of the grinding force. The coupling constant of the thermostat was selected to be 0.1 ps. The interacted distance of the two abrasives perpendicular to the grinding direction is called the transverse interacted distance, La. The interacted distance of the two abrasives along the grinding direction is called the radial interacted distance, Lb. Figure 1(a) shows the first model in which both La and Lb (=6 nm) are nonzero. Figure 1(b) shows the second model, in which only La is nonzero. All the grinding simulations were performed on the (0001) plane and along the direction. The grinding depth, grinding length and speed were set as 2 nm, 17 nm, and 50 m·s −1 , respectively. The relaxation and grinding processes of the abrasives and work material were simulated in the NVT and NVE ensembles, respectively. The two abrasives cut the workpiece simultaneously during the simulation.

Figure 1. Molecular dynamics (MD) model of double-grits interacted grinding of monocrystalline GaN for a radial interacted distance Lb of (a) 6 nm and (b) 0 nm.

2.2. Experimental conditions

To validate the simulated results, an grinding experiment was performed on monocrystalline GaN using a ultraprecision selfrotating grinder, as shown in figure 2. The GaN specimen was 10.5 mm long, 10 mm wide, and 0.35 mm thick. To ensure that the GaN specimen was not damaged during preparation for the grinding test, CMP was performed on the specimen to achieve a surface roughness below 2.0 nm in Ra. Ceramic bonded diamond grinding wheels with mesh size of #8000 and diamater of 125 mm were used in the grinding experiment. The rotational speeds of the wheel and workpiece were 1500 and 100 r·min−1 , respectively. The feed rate was 12 µm·min−1 . Oil coolants were used in grinding process to decrease the grinding temperature and wheel wear. After the grinding test, an TEM sample of the ground subsurface was prepared by using a focused ion beam, and the subsurface damage was analyzed by the crosssectional TEM method. The accelerating voltage, TEM linear resolution, high-resolution TEM (HR-TEM), TEM magnification, and scanning transmission electron microscopy (STEM) magnification of the TEM (Talos F200x, USA) are 200 kV, 0.14 nm, 0.1 nm, 25–1500 000, and 150–2300 000, respectively.

3. Results and discussions

3.1. Grinding force and coefficient of friction

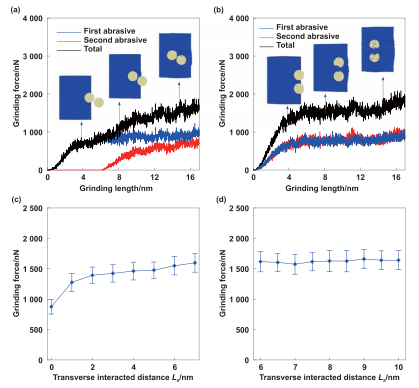

Grinding force is an important index for evaluating the machining effect during the grinding process, and indirectly reflects the material removal process and interaction between the abrasives and workpiece. Figure 3 shows the grinding forces under different interacted conditions. Both figures 3(a) and (b) indicate that as the grinding length increases, the grinding force increases and then stabilizes. Therefore, the average grinding force at the stable grinding stage can be used to analyze the influence of the interacted distance on the grinding force. Figure 3(a) also shows that the grinding force is smaller for the second abrasive than the first abrasive because of the elimination of coupling actions between the two abrasives. Figure 3(c) shows that for Lb = 6 nm and increasing La, the grinding force increases and then stabilizes. This result is obtained because increasing La weakens the coupling between the two abrasives, increasing the contact area between the workpiece and abrasives. Figure 3(d) shows that for noninterfering abrasives, there is a specific La at which there is no discernible coupling between the abrasives and the grinding force is approximately twice that of a single grit, that is, La has no discernible effect on the grinding force.

Figure 3. Grinding force for different interacted distances. (a) Grinding force versus the grinding length for radial and transverse interacted distances of 6 nm and 3 nm, respectively. (b) Grinding force versus the grinding length for radial and transverse interacted distances of 0 nm and 8 nm, respectively. (c) Grinding force versus the transverse interacted distance for a radial interacted distance of 6 nm. (d) Grinding force versus the transverse interacted distance for a radial interacted distance of 0 nm.

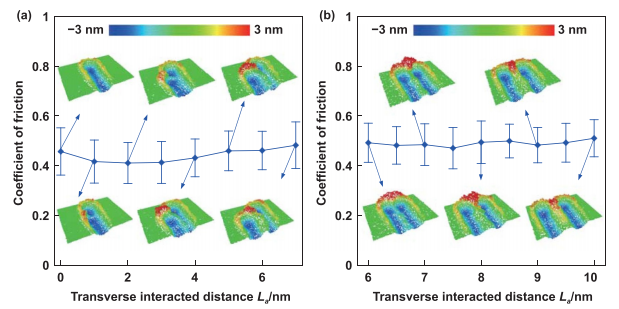

Figure 4 shows the influence of the transverse interacted distance on the coefficient of friction during double-grits grinding of GaN crystals. In this study, the coefficient of friction is defined as the ratio of the tangential force exerted by the abrasive along the grinding direction to the normal force exerted by the abrasive. In figure 4(a), for Lb = 6 nm and increasing La, the coefficient of friction decreases and then increases. The atomic displacements shown in the inset images indicate for La below 3 nm, the contact area between the workpiece and abrasives increases with La. However, there is no discernible increase in the number of atoms that have accumulated in front of the abrasives because of the elimination of coupling between abrasives, which results in the gradual decrease of the coefficient of friction. For La above 3 nm, as La increases, the effect of eliminating the coupling between abrasives weakens and the number of atoms that have accumulated in front of the abrasives increases, resulting in the gradual increase of the coefficient of friction. Figure 4(b) shows that for Lb = 0 nm, La has no discernible effect on the coefficient of friction. Selecting appropriate interacted distances can effectively reduce the friction between the workpiece and abrasives below that of single-grit grinding while ensuring efficient material removal, providing a feasible approach to the wheel design of ordered abrasives.

Figure 4. Coefficient of friction under different interacted distances. (a) Coefficient of friction versus the transverse interacted distance for a radial interacted distance of 6 nm. (b) Coefficient of friction versus the transverse interacted distance for a radial interacted distance of 0 nm. The atomic displacements at different interacted distances are shown in the inset images.

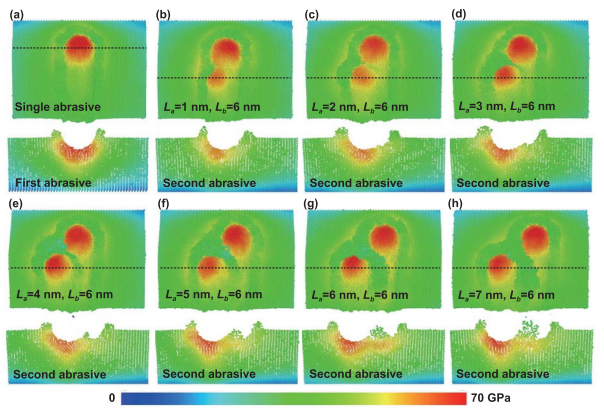

3.2. Stress distribution

The stress investigated in this study corresponds to the von Mises stress, which was calculated by the spatial average method. Figure 5 presents the stress distributions for different transverse interacted distances when the radial interacted distance is 6 nm. The average stress induced by the second abrasive during double-grit grinding (~49.5–57.5 GPa) is smaller than that induced during single-grit grinding (~58.1 GPa) because of the elimination of the coupling to the first abrasive. When the transverse interacted distance is 1 nm, the average stress induced by the second abrasive is 14.8% lower than the average stress induced during single-grit grinding. As the transverse interacted distance increases, the coupling removal of the first abrasive weakens, causing the stress induced by the second abrasive to gradually increase and approach that induced during single-grit grinding.

Figure 5. Stress distributions for different transverse interacted distances and a radial interacted distance of 6 nm. (a) Single-grit grinding, and (b)–(h) double-grit grinding with transverse interacted distances of 1 nm, 2 nm, 3 nm, 4 nm, 5 nm, 6 nm, and 7 nm, respectively.

4. Conclusions

The effect of coupling between abrasives on damage accumulation and material removal during grinding of GaN crystals was investigated by conducting MD simulations of interactive double-grit grinding of monocrystalline GaN. The simulated grinding force, coefficient of friction, stress distribution, plastic damage behavior, and abrasive damage were analyzed. The following conclusions were drawn from the study.

• The results of grinding tests combined with cross-sectional TEM micrographs validate the simulated plastic damage behaviors, i.e. the amorphization transition, the highpressure phase transition, stacking faults, dislocation slips, and lattice distortions. For nonzero interaction distances in both the radial and transverse directions, the damage depth of the ground subsurface increases as the transverse interacted distance increases. There is no clear correlation between the transverse interacted distance and number of atoms in the phase transition and the dislocation length.

• For nonzero distances in both the radial and transverse directions, eliminating the coupling action between the two abrasives results in the second abrasive exerting a smaller grinding force and stress than the first abrasive; as the transverse interacted distance increases, the grinding force and stress increase and then stabilize. Only the transverse interacted distance is nonzero, the stress on the subsurface gradually decreases as the transverse interacted distance increases.

• For nonzero interaction distances in both the radial and transverse directions, elimination of the coupling action between abrasives and the number of atoms that have accumulated in front of the abrasives causes the coefficient of friction to decrease and then increase as the transverse interacted distance increases.

• The amorphization transition is the main form of damage incurred during abrasive wear. Amorphization damage is more severe at the flank face than that at the rake face because of the high elastic recovery of the residual material under a high contact stress. For nonzero interaction distances in both the radial and transverse directions, the amorphization proportion of the first abrasive is smaller than that of the second abrasive for the same scratch lengths. As the transverse interacted distance increases, the amorphization proportion of the second abrasive gradually increases and stabilizes because of the elimination of coupling to the first abrasive.

• Only the transverse interacted distance is nonzero, there is no clear correlation between the transverse interacted distance and the grinding force, coefficient of friction, subsurface damage depth, number of atoms in the phase transition, dislocation length, and abrasive damage.

下一篇: 碳化硅上超高迁移率半导体外延石墨烯