Abstract: Sodium hypochlorite (NaClO) is widely used for the chemical cleaning of fouled ultrafiltration (UF) membranes. Various studies performed on polymeric membranes demonstrate that long-term (>100 h) exposure to NaClO deteriorates the physicochemical properties of the membranes, leading to reduced performance and service life. However, the effect of NaClO cleaning on ceramic membranes, particularly the number of cleaning cycles they can undergo to alleviate irreversible fouling, remains poorly understood. Silicon carbide (SiC) membranes have garnered widespread attention for water and wastewater treatment, but their chemical stability in NaClO has not been studied. Low-pressure chemical vapor deposition (LP-CVD) provides a simple and economical route to prepare/modify ceramic membranes. As such, LP-CVD facilitates the preparation of SiC membranes: (a) in a single step; and (b) at much lower temperatures (700–900 ◦C) in comparison with sol-gel methods (ca. 2000 ◦C). In this work, SiC ultrafiltration (UF) membranes were prepared via LP-CVD at two different deposition temperatures and pressures. Subsequently, their chemical stability in NaClO was investigated over 200 h of aging. Afterward, the properties and performance of as-prepared SiC UF membranes were evaluated before and after aging to determine the optimal deposition conditions. Our results indicate that the SiC UF membrane prepared via LP-CVD at 860 ◦C and 100 mTorr exhibited excellent resistance to NaClO aging, while the membrane prepared at 750 ◦C and 600 mTorr significantly deteriorated. These findings not only highlight a novel preparation route for SiC membranes in a single step via LP-CVD, but also provide new insights about the careful selection of LP-CVD conditions for SiC membranes to ensure their long-term performance and robustness under harsh chemical cleaning conditions.

1. Introduction

Silicon carbide (SiC) ultrafiltration (UF) membranes have found widespread applications in industrial wastewater, produced water, grey water, and surface water treatment. In addition, they are employed as a pre-treatment step prior to reverseosmosis and for pool water filtration in public swimming pools. The popularity of SiC UF membranes stems from their ability to provide: (i) high permeate fluxes due to their hydrophilic nature; (ii) a high-quality permeate irrespective of variation in feed quality; (iii) an excellent hydrothermal stability; (iv) a good stability against pressure and pH gradients; and (v) a high porosity and uniform pore size distribution. Furthermore, various preparation methods are available to obtain SiC membranes, namely,sol-gel, and vapor deposition methods. In general, sol-gel methods require multiple coating cycles of the desired material and high-temperature sintering, which makes the process energy-intensive. In contrast, LP-CVD provides a straightforward method to prepare SiC membranes without the sintering step.

2.were used as substrate

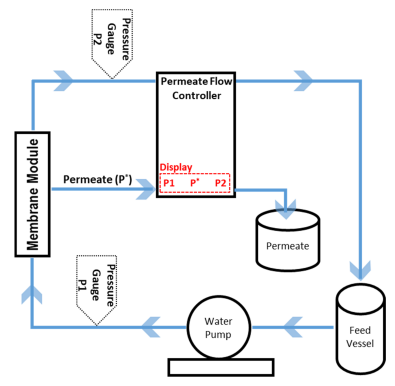

The pure water permeability of the membranes was measured under a constant flux in an in-house built cross-flow filtration setup for tubular membranes using deionized water (Figure 1).

Figure 1. Water permeability measurement setup. P* is permeate flow rate

3. Results and Discussion

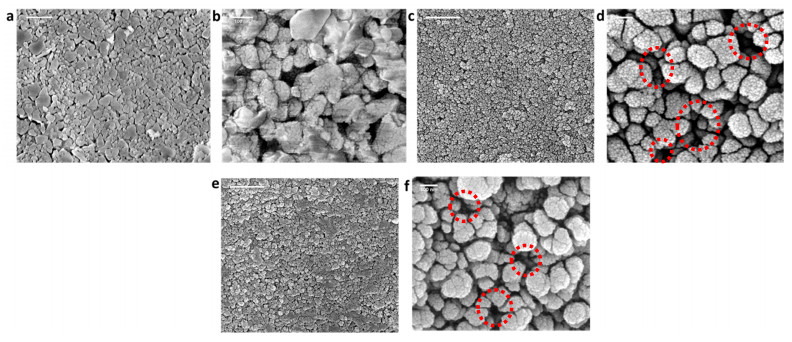

Surface morphologies of the pristine (alumina) and SiC-deposited membranes (SiC-7SiC-8) were analyzed via SEM, as shown in Figure2. The macroporous alumina membranecomprised randomly oriented fine and coarse particles (Figure 2a,b). The discrepancy inshape and size of the alumina particles resulted in a non-homogeneous surface. The surfaceof SiC-7 membrane comprised amorphous SiC nodules, and a decrease in porosity wasobserved in comparison with the alumina membrane (Figure 2c,d). The SiC deposition at860 °C resulted in a continuous dense SiC layer formation, and the decrease in porsitywas larger than that observed for SiC-7 (Figure 2e,f). Our observations are consistent withthe LP-CVD growth mechanisms reported previously, i.e., when SiC is deposited on a foreign substrate (which, in this case, is Al2O3), the grwth proceeds via the three-dimensionalVolmer-Weber island growth mechanism. At the low-deposition temperature of 750 °Cthe growth kinetics were slow, leading to the formation of distinct SiC islands, which subsequently grow into SiC nodules, as suggested by Greene. However, at a high depositiontemperature of 860℃, fast growth kinetics led to the coalescing and growth of SiC nodulesto form a homogeneous and continuous layer. The intrinsic stress, intrduced dueto either deposition conditions or mismatch in thermal coefficients between the substrateand deposited material, is greatly reduced by the transition in morphology of SiC fromnodules to a continuous layer. Consequently, the growth of a continuous SiC layerwill properly shield the Alz0s particles, and hence the interfacial energy between Al203 substrate and a SiC layer will be minimized 40, leading to the enhancement of adhesionstrength between the SiC layer and Al2Os substrate.

Figure 2. Surface morphology analysis via SEM of (a,b) the pristine alumina membrane; (c d) SiC-7membrane; and (e,f) SiC-8 membrane. Red circles highlight the difference in porosities.

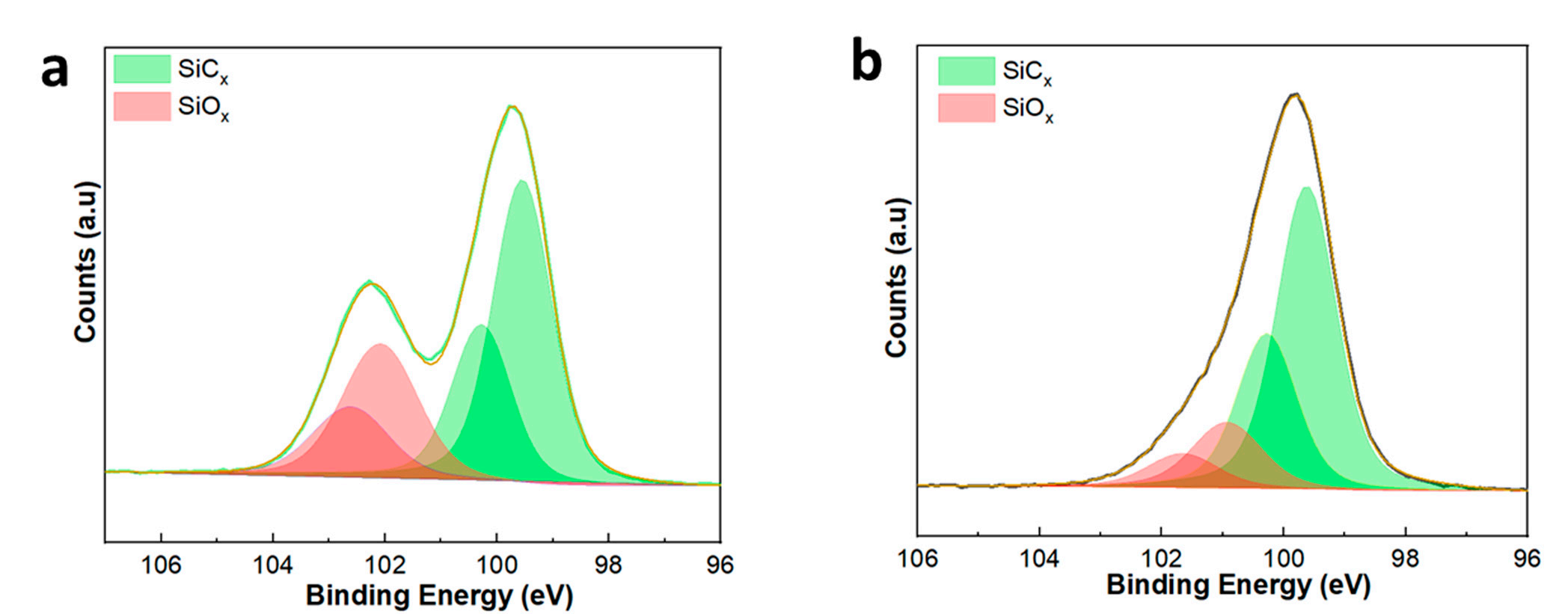

XPS was performed to study the elemental makeup of the SiC membrane surfaceFigure 3a,b presents the Si 2p XPS spectra of the SiC-7 and SiC-8 membranes. In both casesthe Si 2p peaks were deconvoluted into four peaks, confirming the presence of Si, both inthe form of oxides (Si0,) and carbides (SiC ). The presence of the Si-C4 peak ata binding energy of ~99.5 in Figure 3a, and the presence of the Si-C4 peak at a bindingenergy of ~99.6 in Figure 3b confirm the deposition of SiC via LP-CVD. The presenceof Si-C3-0, Si-C2-02/Si-C-03, and Si-04 suggests that the SiC is of amorphous nature.

Figure 3. XP-spectra of (a) the SiC-7 membrane; and (b) the SiC-8 membrane.

4. Conclusions

SiC UF membranes were prepared under two different deposition conditions via LP-CVD. As-prepared SiC membranes were aged in NaClO for 200 h. Afterward, the effect of aging on the properties and performance of the SiC membranes was studied.

SEM images coupled with EDX spectra of as-prepared membranes showed that a ca. 9 µm thick SiC-selective layer was formed after LP-CVD. Under high-temperature deposition conditions (860 ℃ and 100 mTorr), a continuous film of a SiC-selective layer was obtained. On the other hand, under low-temperature deposition conditions (750 ℃ and 600 mTorr), SiC was deposited in the form of amorphous nodules. Pure water permeability and pore size measurements revealed that the SiC deposition at a high temperature led to the formation of a robust SiC-selective layer which was stable in NaClO for 200 h. Additionally, XPS and SEM results demonstrated that SiC deposited at a low temperature completely deteriorated after 200 h of NaClO exposure.

上一篇: 用于微系统异构集成的硅酸盐基封装材料

下一篇: GaN 半导体薄层电阻的宽带涡流测量