ABSTRACT

Microwave plasma chemical vapor deposition (MPCVD) is regarded as one of the most promising techniques for the preparation of large-scale and high-quality epitaxial single-crystal diamonds. This review paper provides an overview of recent advancements in MPCVD single-crystal diamond growth, including discussions on the growth mechanism, substrate holder design, and seed crystal screening and pretreatment for achieving homogeneous epitaxial single-crystal diamond. Key growth parameters such as temperature, methane concentration, power density, etc., are investigated to guide the atainment of optimal growth conditions. Furthermore, critical growth techniques like three-dimensional growth, repeated growth, and mosaic splicing are analyzed to enhance the area coverage of single-crystal diamonds. The work on achieving low defect and high purity growth is also elucidated. Additionally, this paper discusses the progress made in n-type and p-type doping of diamond materials. Finally, a summary is provided highlighting the challenges encountered during MPCVD single-crystal diamonds growth.

1 Introduction

The diamond possesses exceptional properties, including unparalleled hardness, superior thermal conductivity, minimal thermal expansion coefcient, excellent resistance to radiation, acid, and alkali, high optical transmitance across a wide spectrum range . Notable, the diamond exhibits a wide bandgap of approximately 5.5 eV and remarkable electron–hole saturation velocity, rendering it one of the most promising semiconductors. Consequently, diamond holds immense potential for diverse applications such as ultra-precision processing, heat sinks, optoelectronics, quantum computing and semiconductor electronic devices. Therefore, the acquisition of high-quality large-size single-crystal diamonds (SCD) is crucial for these aforementioned felds. Unfortunately, natural diamonds sufer from drawbacks like impurities abundance limitations and exorbitant cost that hinder their suitability for fundamental research and industrial applications. Therefore, synthetic diamonds have garnered signifcant atention in recent years.

In addition to the growth rate and crystal quality, the preparation of large-sized diamonds has posed a signifcant challenge for scientists both domestically and internationally. With the rapid advancement of 5G communication technology, diamond materials have gained increasing importance in semiconductors and high-frequency power devices. Diamonds play a crucial role in implementing major national strategies such as ultra-precision processing, smart grids, intelligent manufacturing, and 5G communication upgrades. The industrialization breakthroughs in this technology are vital for ensuring China’s independent security in its intelligent manufacturing and big data industries. Therefore, research on diamond materials must primarily focus on developing larger sizes with reduced defects, enhanced resistivity, and higher thermal conductivity. Currently, numerous domestic and international research institutions are actively engaged in MPCVD diamond growth studies that prioritize high-speed production while maintaining stringent quality standards.

The novelty of this paper is that it provides a comprehensive review of the research progress of MPCVD monocrystalline diamond growth, including growth mechanism, substrate scafold design, seed crystal screening and pretreatment, growth parameter optimization, three-dimensional growth techniques, low defect and high purity growth, and doping studies. Furthermore, we present the current research progress on achieving high-quality single-crystal diamond growth over large areas. Lastly, a comprehensive analysis is conducted on the extensive application prospects of MPCVD single-crystal diamonds in electronics.

2 Growth of diamond

Recently, it has been proposed that diamond generation is a phase transition from the graphite phase, challenging the conventional understanding of diamond phase formation through atomic hydrogen etching of graphite/sp3 carbon accumulation. In the cycle of this phase transition, as illustrated in Fig. 1, (A) at 0s: initial rod-like diamond crystals—(B) after 30s: long and fexible vertically growing graphene sheets (VGs) emerge—(C) at 60s: VGs straighten with their heads bending—(D) at 90s: VGs disappear and some straighter and thicker graphite nanorods appear, indicating the onset of diamond formation— (E) for the sample at 120s: numerous nanodiamond crystals are exposed on the edges of caulifower-like particles covering the graphite nanorods—(F) at 150s: VGs reappear—(G) by180s: straight and thick VGs are observed—(H) in 210 s: a district rich nanodiamond (area 1), once again covers graphite rods (area 2). Thus, each cycle lasting for approximately 90 s represents a phase transition process where diamond grains do not grow solely through carbon atoms accumulation to form sp3 structures but rather undergo transitions from graphite during CVD.

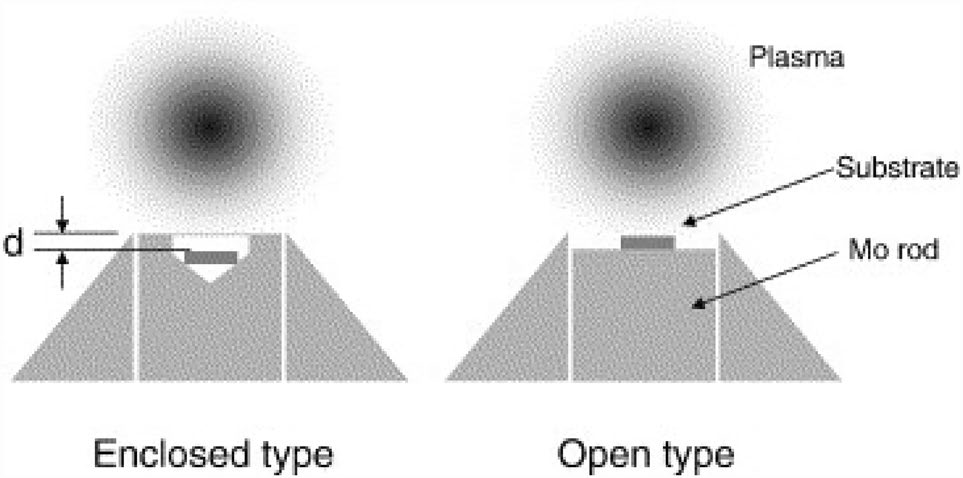

Currently, there are primarily two types of MPCVD substrate holders: enclosed and open (Fig. 2). The enclosed holder exhibits a more uniform temperature feld, efectively suppressing the formation of hillocks or non-epitaxial crystallites, thereby ensuring superior crystal quality; however, it has a relatively lower growth rate. On the other hand, the open structure enhances both microwave power density and growth rate. Nevertheless, this design sufers from a large temperature and signifcant edge polycrystalline efect that restrict the lateral expansion of single-crystal area . Mokuno et al. observed that the “open type” tends to form protruding “pyramid” surfaces while the “enclosed type” yields comparatively smoother diamond surfaces that efectively inhibit edge polycrystalline growth. Figure S1 shows optical microscope (OM) images of grown diamond after 1st growth (left) and repetition of growth (right) for open and enclosed type holder. The flm thickness is indicated in each picture. A dashed circle indicates a crack formed by repetition of high rate growth.

Fig. 2 Schematic illustration of ‘‘enclosed type’’ and ‘‘open type’’ holders. d indicates the fnal depth of the diamond relative to the top holder after growth.

After 24 cycles of growth using an “enclosed” holder, a growth rate of 68 μm/h is achieved leading to synthesis of large-sized CVD SCD with a thickness of 1 cm. Conversely, for an “open” holder, although the initial growth rate reaches 87 μm/h, further cycles cannot proceed without polishing treatment due to crack formation in the center. In contrast, by using enclosed type holder, the surface morphology is dramatically improved and smooth and fat surface morphology without growth hillocks or no epitaxial crystallites is obtained even after the 5th growth.

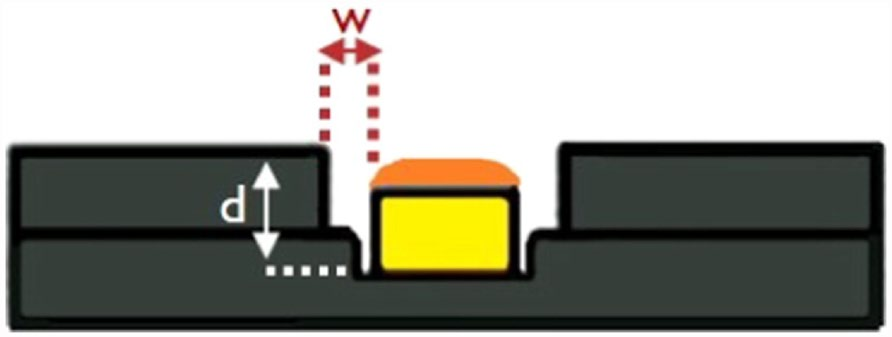

To mitigate the edge effect, Nad et al. enhanced the design of the “open type holder”, as depicted in Fig. 3. By employing a stepped (“pocket holder”) structure, they successfully deposited enlarged area of smooth and low-stress single-crystal diamond on the top growth surface of the protruding seed crystal, with its top surface positioned inside and below the opening of the pocket. This achievement was made possible by adjusting the depth (d) of the pocket holder, efectively suppressing any occurrence of polycrystalline regions at the edges.

Fig. 3 Pocket type holder for SCD deposition. The yellow region represents the cross-section of an HPHT seed placed in a recess and away from the intense plasma region.

By employing the MPCVD technique, homoepitaxial single-crystal diamonds already possess desirable characteristics and are well-suited for a diverse range of applications, particularly in achieving thermal and electrical industrialization. To further unlock the potential of this material for numerous applications and technologies, it is imperative to continuously enhance the size and quality (while reducing manufacturing costs) of CVD SCDs, as well as minimize defect density and achieve precise doping.