ABSTRACT

Silicon, renowned for its applications in electronic circuits, also offers significant advantages in the realm of integrated optics. While silicon does have inherent limitations in fabricating active devices, these challenges can be overcome through heterogeneous integration with other materials. Ferroelectric materials like lithium niobate (LN) and barium titanate (BTO) exhibit exceptional electrical and nonlinear optical properties, making them ideal candidates for integrated silicon photonics. Over the past few decades, the LN platform has made substantial progress, surmounting obstacles such as manufacturing difficulties, high waveguide losses, and low modulation bandwidth caused by wide electrode spacing. Consequently, LN-based devices have found widespread application in various fields. With the advent of high-quality, large-size LN on insulator wafers, LN photonics has become a burgeoning research area. At the same time, the ferroelectric material BTO, with its tremendous electro-optic response, shows promise for the next generation of integrated photonics. Recent studies have highlighted the remarkable performance of BTO-based modulators, which offer smaller device sizes compared to LN by achieving lower half-wave voltages. This comprehensive review presents various fabrication methods for integrating LN and BTO thin films on silicon, focusing on recent advancements. We discuss their electro-optic responses and provide an overview of the diverse applications enabled by these platforms. Finally, we summarize the current state of integrated LN and BTO photonics research and offer insights into future directions.

I. INTRODUCTION

Electro-optic (EO) effect is the foundation that links electrical and optical signals, modulating light by changing the refractive index of materials through an electric field. With the rapid development of nonlinear optics, lasers, and electronics, the EO effect has been widely applied in fields such as high-speed optical modulators and all-optical chips. The propagation of light waves in a crystal can be influenced by the EO effect, leading to the formation of key devices in the field of optical communication such as EO modulators, EO filters, beam deflectors, and tunable filters. EO modulators are critical components in modern telecommunications networks and microwave photonics systems, allowing the modulation of electronic signals into optical signals with parameters such as phase, amplitude, and polarization. These modulators also play important roles in emerging fields such as quantum communication, quantum computing, and photonics neural networks.In recent years, with the development of next-generation communication technology and photonic chips, data modulation and transmission capacity are facing higher and higher requirements.5G communication technology and subsequent 6G communication technologies have increasingly high demands for data modulation and transmission capacity. The integration of all-optical networks and terahertz frequency band (0.1–10 THz) wireless communications is seen as a key technology to meet data transmission rates of 100 Gbps or even 1 Tbps. This undoubtedly places higher demands on optical modulators as signal conversion devices, requiring them to achieve both high transmission rates and low energy consumption. Traditional optical modulators rely on bulk materials such as lithium niobate (LN), where the waveguide has weak constraints on the beam diameter. This leads to a large spacing between the modulation electrodes, which significantly limits the modulation bandwidth of LN modulators. Although silicon modulators can achieve optical modulation through physical effects such as plasma dispersion, thermal-optical effects,or others, their EO effect is weak. While modulation efficiency can be improved by adjusting the width of the depleted region of the PN junction, silicon itself is not an ideal EO material. Thanks to the development of integrated photonics, III-V materials,silicon-on-insulator (SOI), and silicon nitride (SiNx) platforms have been extensively studied. It is expected to achieve highly integrated new EO modulators by integrating strong EO active materials on silicon.

Integrated photonics based on ferroelectric materials have been extensively studied due to the rich physical effects present in ferroelectric materials, such as EO, acousto-optic, and nonlinear-optic effects. In the past few decades, LN has been widely used in the field of EO modulation due to its excellent EO properties. Compared with other systems such as silicon (Si), indium phosphide (InP),SiNx, and Plasmonics, the LN modulator has the advantages of small size, high bandwidth, low loss, and good linearity. Traditional LN modulators are waveguide devices made by proton exchange (PE) or Ti-diffusion processes, and the refractive index difference Δn (≈0.02) of these LN waveguides is relatively low. As a result, their ability to limit light is weak, leading to relatively large device volumes and higher modulation voltages. This is not in line with the current trend of high efficiency and high integration, which has greatly limited the development of LN photonics. In recent years, with the rapid development of SOI technology, people have attempted to fabricate thin LN (TFLN) on the SOI platform, forming LN on insulator (LNOI). These insulators typically have lower refractive indices, which makes LNOI possess a high refractive index contrast. LNOI can realize more compact LN waveguide devices through etching and other processes. Efficient waveguide devices based on the TFLN platform have been demonstrated, including EO modulators, integrated femtosecond pulse lasers, etc.TFLN photonics has shown enormous potential for applications.

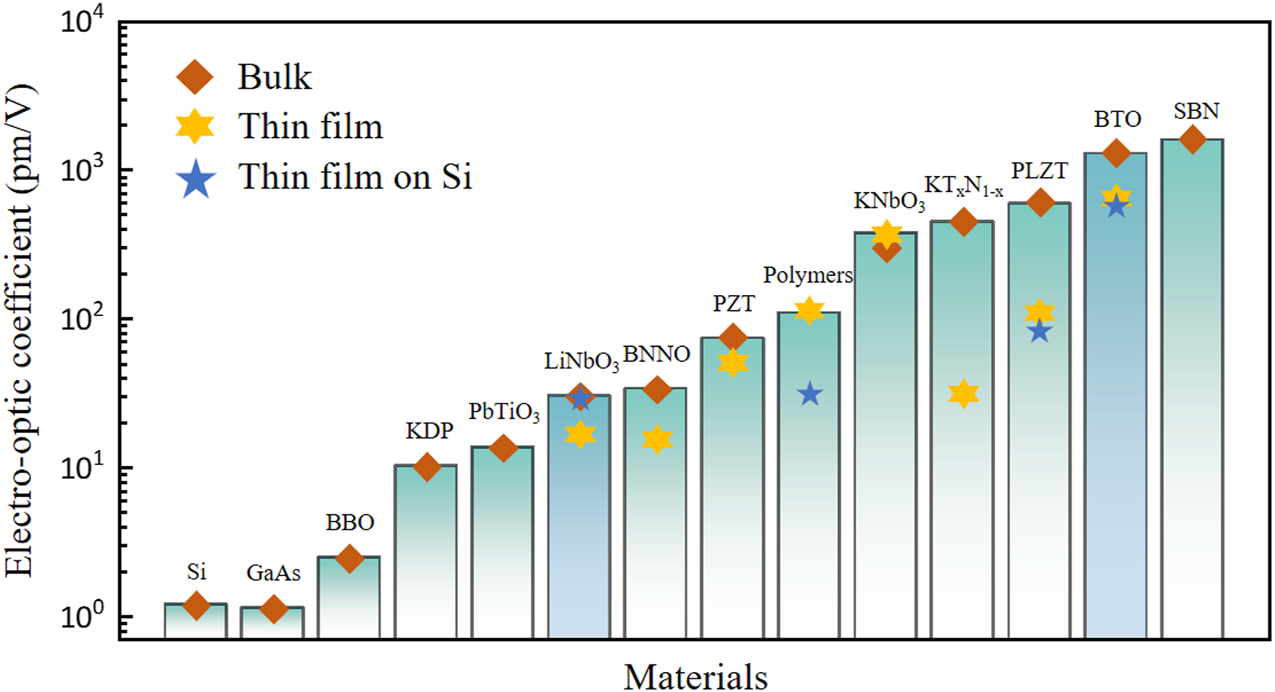

Recently, another ferroelectric material, barium titanate (BTO), has received wide attention in the field of integrated photonics.Among the many ferroelectric materials, BTO exhibits one of the strongest Pockels effects. As shown in Fig. 1, BTO exhibits a Pockels coefficient that is an order of magnitude higher than that of LN. BTO can be integrated with silicon platforms through direct deposition, and various methods, including pulsed laser deposition (PLD), molecular beam epitaxy (MBE), and RF sputtering, have been employed for the Si-based epitaxial growth of BTO films. Currently, LN and BTO photonics are still in the early stages of development. Extensive research has been conducted on their material properties, and numerous new photonics devices have been demonstrated, such as high-speed EO modulators, acousto-optic modulators (AOMs), and optical frequency combs (OFCs), among others. Thin-film LN and BTO photonics devices are expected to find applications in multiple fields, including nanophotonics, quantum information processing, and alloptical networks.Certainly, other ferroelectric materials have also been extensively studied for use in photonics, including Lead Zirconate Titanate (PZT), Lead Magnesium Niobate-Lead Titanate (PMN-PT),and Lithium Tantalite (LT). A halfwave voltage-length product of 1.4 V cm for PZT heterogeneously integrated optical modulators has been reported. However, leadcontaining materials require consideration of various factors due to their environmental and body unfriendliness during fabrication and use. PMN-PT faces similar issues. Despite its significant Pockels and Kerr effects in bulk form, fabricating and processing challenges have limited its attention in integrated photonics. Additionally, the properties of multicomponent compounds are greatly influenced by the elemental ratios. PZT and PMN-PT exhibit excellent piezoelectric and EO properties near the morphotropic phase boundary (MPB), but this complex domain structure undoubtedly increases the difficulty of device design. The LT/Si photonic platform confronts the challenge of low tuning efficiency (12.8 pm/V). For LN, which is already commercialized, and BTO, which holds great potential, these issues seem more manageable.

FIG. 1. Pockels coefficient of various materials in different types, including bulk, thin film, and thin film on silicon.

II. MATERIAL PROPERTIES

LN is a typical nonlinear optical crystal with excellent optical properties, such as high optical nonlinearity, high spontaneous polarization, and excellent optical transparency. It exhibits good transmittance from visible light wavelengths (420 nm) to midinfrared (5 μm). Its nonlinear optical coefficient is ∼30 times that of silicon, making it one of the key materials widely used in optical modulators and optical switches. LN belongs to the trigonal system with the space group R3c and exhibits threefold rotational symmetry along the c-axis. In the crystal lattice of LN, each niobium (Nb) atom is surrounded by six oxygen atoms, forming an octahedron. Lithium (Li) atoms are similarly situated within the octahedra. The lattice parameters of LN are a = b = 5.148 Å, c = 13.863 Å, α = β = 90○ , and γ = 120○.

III. LN THIN FILM

In the past few decades, significant efforts have been dedicated to obtaining high-quality LN thin film. Various methods have been utilized to fabricate LN thin films, including molecular beam epitaxy (MBE),pulsed laser deposition (PLD), chemical vapor deposition (CVD), and RF sputtering. Nevertheless, these methods require careful substrate selection for LN thin film growth due to lattice matching issues. Despite the successful fabrication of LN thin film on substrates such as sapphire (Al2O3), LiTaO3, and SiC, the challenge of attaining high crystallinity in the films has significantly impacted their electrical and nonlinear optical properties.

Ion slicing technology provides a new approach to the fabrication of high-quality thin films (LN). This involves ion implantation into a crystal wafer to create a buried layer, which exhibits selective etching between the buried layer and the wafer. The LN thin film is then separated from the bulk material and bonded to a substrate. However, the LN films obtained using this method have a larger thickness, which makes it difficult to fabricate a heterogeneous structure, thus limiting their application range. The emergence of LNOI technology has enabled the fabrication of high-quality TFLN. Based on ion slicing technology or direct deposition processes, bonding the LN thin film onto an insulating layer (higher refractive index contrast) is crucial for subsequent device fabrication. Then, through other processes such as high-temperature annealing and mechanical polishing, a high-quality LN thin film with a controllable thickness is achieved. This technology has greatly contributed to the further development of LN photonics.

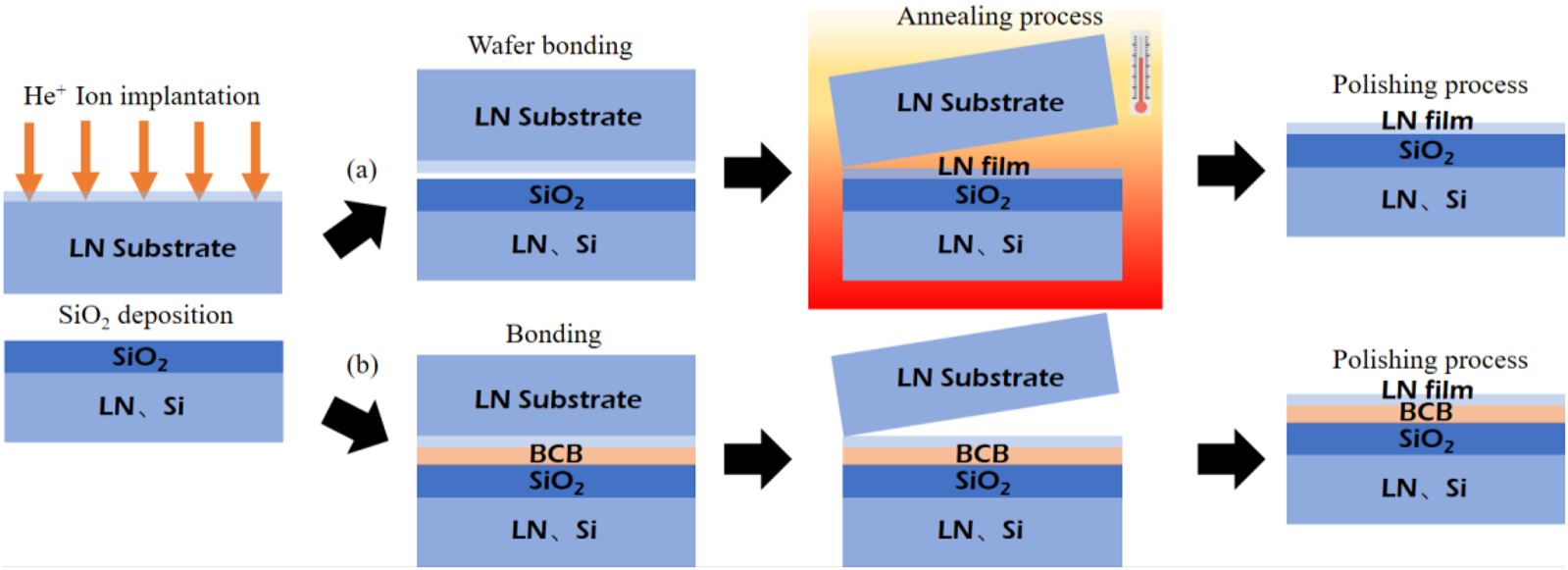

The complete fabrication process of the LNOI platform is illustrated in Fig. 3. In the first step, the LN wafer undergoes helium ion implantation at high intensity to create a buried damage layer within the target material. SiO2 (a few micrometers thick) is deposited on the substrate by chemical vapor deposition. The substrate can be an LN wafer or a Si wafer. The LN is then bonded to the substrate using direct wafer bonding [process depicted in Fig. 3(a)] or adhesive bonding [process depicted in Fig. 3(b), with benzocyclobutene (BCB) as the adhesive].Subsequently, heat treatment is used to separate the LN film from the LN substrate and bond it to the LN wafer. High-temperature annealing and mechanical polishing can improve the quality of the LN film, ultimately leading to the fabrication of high-quality TFLN. Currently, large-area, high-quality LN single crystal films have been successfully achieved through ion slicing technology, and commercial products are readily available.This section provides a concise summary of the fabrication process for TFLN. Detailed steps can be obtained from other literature sources.

FIG. 3. The fabrication process of LN on SOI substrates includes ion implantation and SiO2 deposition. (a) Annealing and polishing are performed after direct wafer bonding. (b) TFLN is bonded to the substrate by BCB adhesive.

Ion-cutting and wafer bonding techniques enable the fabrication of TFLN with high refractive index contrast (Δn ≈ 0.7), providing strong confinement for light. The next step is to fabricate waveguides on the TFLN platform. The types of TFLN waveguides need to be taken into consideration. TFLN waveguides can be categorized into several types: exchanged waveguides, rib-loaded waveguides, ridge waveguides, and SOI-bonded waveguides. The schematic diagram of various TFLN waveguide structures is shown in Fig. 4. In this section, we discuss the fabrication methods and characteristics of these TFLN waveguide structures.

FIG. 4. Common waveguide structures based on TFLN include (a) Ti-diffused or proton-exchanged, (b) rib-loaded, (c) dry-etched,

and (d) SOI bonded.

V. CONCLUSIONS AND OUTLOOKS

With the rich physical effects offered by ferroelectric materials, LN and BTO have emerged as excellent materials for heterogeneous integration on Si. Over the past few decades, LN has secured a pivotal role in modern photonics, a status attributed to the technological sophistication and extensive commercialization of this material. With the continuous development of modern processing and manufacturing techniques, many challenges in the TFLN waveguide have been gradually overcome. Recently, a TFLN photonics integrated circuit (PIC) on a six-inch wafer has been demonstrated, which achieved propagation losses below 0.3 dB/cm through deep ultraviolet lithography etching. This achievement indicates progress toward large-scale, economically viable, and low-loss LNOI wafer fabrication. The exceptional nonlinear optical properties of the LNOI platform have found extensive applications in EO modulators and optical frequency conversion. The development of EO devices based on TFLN has been ongoing for several decades, and TFLN EOM with modulation bandwidth exceeding 100 GHz has been demonstrated. Other groundbreaking devices such as LN acousto-optic modulators (AOM), rare-earth-doped devices (lasers and on-chip integrated lasers), and other heterogeneous devices have also been reported. Additionally, second-order and third-order nonlinear effects have been demonstrated for various applications in TFLN. Considering the stronger mode confinement of TFLN compared to bulk LN, TFLN holds the potential for achieving higher nonlinear conversion efficiency in the future. Integrated quantum optics, which is currently in its early stages, has received significant attention, and we can anticipate the realization of fully integrated optical quantum chips on the TFLN platform.

下一篇: 半导体制造中的多级过程诊断网络