Abstract: Detecting subsurface defects in optical components has always been challenging. This study utilizes laser scattering and photothermal weak absorption techniques to detect surface and subsurface nano-damage precursors of single-crystal silicon components. Based on laser scattering and photothermal weak absorption techniques, we successfully establish the relationship between damage precursors and laser damage resistance. The photothermal absorption level is used as an important parameter to measure the damage resistance threshold of optical elements. Single-crystal silicon elements are processed and post-processed optimally. This research employs dry etching and wet etching techniques to effectively eliminate damage precursors from optical components. Additionally, detection techniques are utilized to comprehensively characterize these components, resulting in the successful identification of optimal damage precursor removal methods for various polishing types of single-crystal silicon components. Consequently, this method efficiently enhances the damage thresholds of optical components.

1. Introduction

Optical component processing typically involves grinding, polishing, shaping, and other abrasive-based processing technologies. These processes generate small brittle/plastic cracks, scratches, and other physical defects on the surface of the components. These defects not only affect the mechanical properties of the optical element, but also greatly impact its optical properties. Additionally, residual chemical contamination from polishing abrasives and other chemical contaminants can cause laser-induced damage in high-energy/highpower laser systems, resulting in optical component failure. In high-energy laser systems, cracks, contamination, and other factors that cause laser-induced damage to optical elements constitute damage precursors. The distribution characteristics of weak absorption on the surface of fused silica optics post-treated with different processes and 355 nm laserinduced damage properties were investigated by Shi et al. The correlation between defects with different absorption levels and the damage performance of fused silica surfaces was systematically investigated. It is shown that there is a significant correlation between the density of defects with absorption above 2 ppm and the damage performance. Feng Shi studied the evolution of several nanoscale damage precursors in shallow IBE, and found that IBE can eliminate the polished redeposited layer and weaken the surface densification. It is important to determine the intrinsic properties of nanoscale damage precursors in terms of surface laser damage resistance. Damage precursors originate from the processing, handling, coating, and other processes of optical components. Therefore, it is necessary to monitor and control damage precursors throughout the entire processing of optical components to ensure that they meet the requirements of high-energy laser systems. Silicon-based materials are widely used in infrared thermal imaging systems due to their good spectral properties in the mid-infrared region. In high-power continuous laser systems, silicon-based materials are commonly used as cavity mirrors, mirrors, and other optical components due to their excellent integrated thermal performance ratios and midinfrared optical properties. The quality of the mirrors directly determines the performance of the laser system. With the development of high-power lasers, the lenses in laser systems need to withstand higher and higher power densities, and the most important limiting factor for the performance of the lenses is the damage precursor.

During the grinding and polishing of silicon lenses, monocrystalline silicon, beinga brittle material, is prone to cracks, impurities, and other defects. Figure 1 illustratesthe common defect distribution of optical materials after grinding and precision polishingSurface and subsurface cracks, as well as impurity metal elements, may be present. Thesedefects can be suppressed as the level of processing increases, and a layer of hydrolysisforms below the surface of the element. In brittle materials such as monocrystalline siliconthe hydrolysis layer is a layer with a refractive index comparable to that of silicon, butamorphous. Beneath the hydrolysis layer is a layer of subsurface crushing defectswhich includes many scratches and cracks due to grinding and polishing, as well as a layerof defects enriched by polysilicon. Further below is a structural defect layer brought to thesubstrate by the grinding and extrusion process.

Figure 1. Surface defects and subsurface defects in single-crystal silicon components after processing.

Extensive research has established a consensus that laser-induced defect sites reducethe laser damage resistance of optical materials. In continuous high-energy lasersystems, the difference between the light absorption caused by defects and the bodymaterial creates a significant stress mismatch at the defect site. When the aberration causedby the stress mismatch exceeds the intrinsic cracking strength of the material, laser-induceddamage occurs. Surface and subsurface defects in optical elements can extend toaffect functional multilayers, leading to damage due to nodule-type defects during intenselaserloading. Additionally, the presence of defects on the surface ofan optical element whenirradiated by an intense laser leads to a large amount of heat generation under prolongedhigh-energy laser irradiation of the element. Surface and subsurface damage precursorsare highly susceptible to stress differences between the defects and the body materialunder the action of the thermal field, Such stress differences can lead to deformation oreven damage in the local region of the element. Therefore, the existence of thesedefects can significantly reduce the damage resistance of the film layer and even the entireoptical element. It is, therefore, necessary to establish a means of detecting damage fromsurface/subsurface laser-induced thermotropic damage mechanisms in optical elements.

2. Experimental

In our study, monocrystalline silicon optics were selected for each of the three different processing processes. All monocrystalline silicon crystals have an orientation of 100, a diameter of 50 mm, and a thickness of 5 mm. Bonnet polishing (BP) allows for uniform polishing over large areas and improves the surface finish of optical elements, but for high surface roughness and raised defects, multiple passes may be required to achieve the desired smoothness. However, for defects with high surface roughness and raised surfaces, multiple polishing passes may be required to achieve the desired smoothness. Chemical– mechanical polishing (CMP) is capable of treating surfaces of various shapes and edges, and is effective in removing small defects such as scratches and oxidized layers. However, the polishing process is more complex and requires control of the concentration, flow rate and time of the polishing solution. Magnetorheological polishing (MRF) can be performed on surfaces with unconventional shapes such as spherical and aspherical surfaces. However, the preparation of the polishing solution is more complicated and requires the configuration of special magnetorheological fluids. We provide the corresponding processes for each single-crystal silicon optical element in Table 1.

Table 1. Three sample-polishing processes.

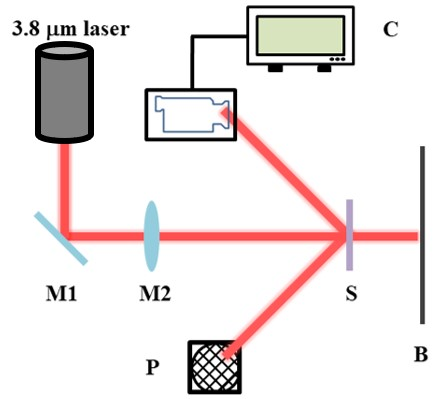

For the characterisation of the final damage test, we used the optical path shown in Figure 2. The laser outputs a 3.8 µm laser, which is focused by a lens and then irradiates the optical element. Prior to the laser damage threshold test, the laser output power and spot size were measured, the sample test spot was placed in the laser light path and irradiated using individual laser pulses of different energy densities. For each selected pulse energy, at least five test points were irradiated and recorded, and the actual pulse energy used for each test point was recorded using a beam diagnostic device. The condition (damaged or undamaged) of the sample after laser irradiation was also recorded. This test was repeated for other pulse energies. The range of pulse energies used should be wide enough to ensure that the minimum energy value will not cause damage to any of the sample test points. The maximum energy value is capable of damaging every sample test point, and damage threshold data are obtained using the damage probability method.

Figure 2. Schematic diagram of the damage test light path. The laser is 3.8 um, M1 is an all-reflectivemirror, M2 is a focusing lens set, S is a sample,C is an online damage-monitoringCCD, P is a reflectedlight collection energy meter, and B is a transmitted light collection bin.

3. Result and Discussion

Scattering test techniques enable the detection of micro and nano-level surface defects of optical components [43,44]. As shown in Figure 3, the bonnet-polished sample(Figure 3a) exhibited numerous scattering points, and the surface quality was poor, withmore pockmarks and scratches. The CMP-polished sample (Figure 3b) also had morescratches and pockmarks on the surface, but the number of pockmarks was significantlyreduced compared to the bonnet-polishing process. In Figure 3c, the number of scratchesin the MRF-polished samples is significantly lower than that in the CPM-polished samplesand the number of pockmarks is less than that of the previous two processes, with a signifi.cant improvement in the surface quality of the samples. By comparing these three processeswe conclude that the MRF process can effectively remove scratches and pockmarks on thesurface of the sample, and repair the roughness and surface shape of the sample.

Figure 3. Scattering test plots of samples from different polishing processes. (a-c) Bonnet-polishingprocess, chemical-mechanical polishing process, and magnetorheological polishing process, inthat order.

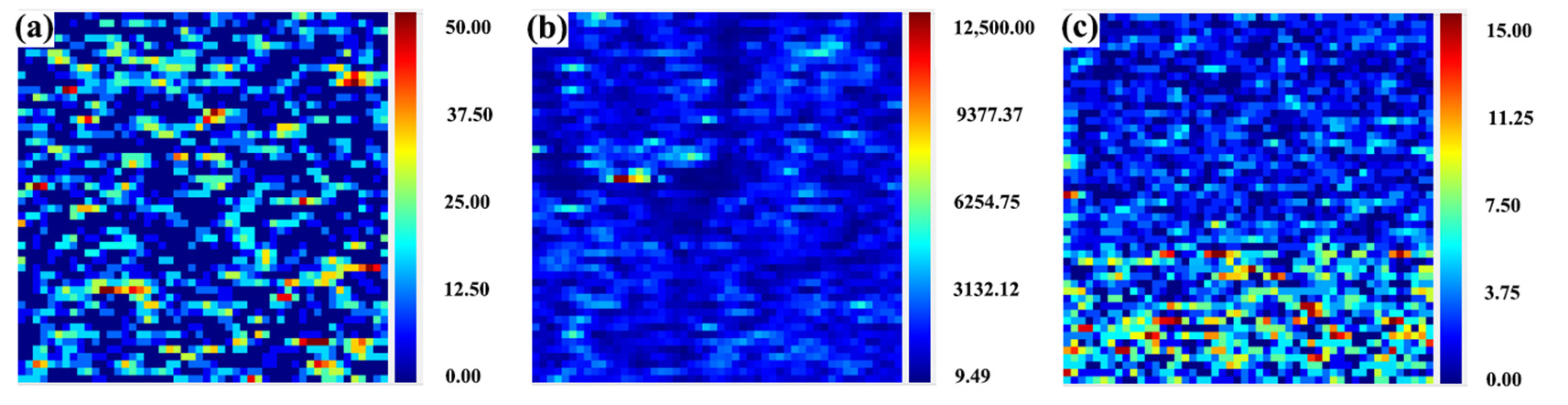

Figure 4 presents the photothermal weak absorption test results of samples withdifferent polishing processes. The photothermal weak absorption technique enables thedetection of subsurface defects ofoptical elements. As shown in Figure 4, the distributionof subsurface defects of bonnet-polished samples is more extensive and covers a largerarea. This distribution is mainly due to the bonnet-polishing process, which uses flexiblebonnets and abrasive materials to smooth out scratches or defects on the surface of theoptical element. However, craters and deep scratches cannot be removed, resulting in a large area of weak absorption test results. This also explains the reason for the highnumber of pockmarks in the scattering test. CMP polishing involves the addition ofabrasive materials in the chemical solution to polish the optical element. However, thepolishing solution contains elements such as cerium, which introduces metal elements andresults in very highly weak absorption values. The MRF polished samples have fewersubsurface defects compared to the previous two processes, and their distribution range issmaller than that of the bonnet-polished samples. Table 4 provides the specific values ofweak absorption for these three polishing pmcesses.

Figure 4. Photothermal weak absorption test plots of samples with different polishing processes(a-c) bonnet-polishing process, chemical-mechanical polishing process and magnetorheological polishing process, in that order.

Figure 6 presents the photothermal weak absorption detection results. It can be observed that there are numerous discrete absorption defects on the surface of all the samples. The highest value of photothermal weak absorption for the wet-etched sample is one order of magnitude lower than that of the dry-etched sample. Combining the photothermal test results of the unetched samples, we found that the average and peak values of weak absorption for the samples polished by the MRF process are lower than those of the samples processed by the other two processes. The samples processed by the MRF process have a more uniform distribution of impurity metal elements on the subsurface, and fewer defective spots or pits on the surface. For samples of the same process, wet etching is superior to the other two processing process. Dry etching causes a certain change in the surface quality of the samples, but due to the possibility of contamination of the samples during the etching process, the effect of post-processing is not very significant. Therefore, we conclude that for silicon optical elements, wet etching can be the optimal means to effectively remove defects present on their surfaces and subsurfaces. The results demonstrate that the weak absorption detection technique is good for non-destructive detection of subsurface defects in single-crystal silicon optical devices. However, due to the relatively macroscopic measurement results, it is difficult to identify the morphology or shape of the defects. This signifies a potential area for future research.

Figure 6. Photothermal weak absorption test plots of samples with different processes after wetand dry etching. Panels (a-c) show the dry etching of samples from the bonnet-polishing, chemical-mechanical polishing, and magnetorheological polishing processes, respectively. Panels (d-f) showthe wet etching of samples from the bonnet-polishing,chemical-mechanical polishing, and magne.torheological polishing processes, respectively.

During our damage testing process, we set a requirement that the test energy step should not be less than 5, and each energy step test point should be 5. We recorded the highest energy density when no damage occurred and the energy density when damage occurred. We then calculated the average value of these two values for each point, which represents the damage threshold of the point. We averaged the damage threshold of all the test points to obtain the damage threshold of the sample. The sample testing environment was a class 10,000 clean room with a humidity of 45.6%. The laser-emitting surface was used as the sample-testing surface, and acetone and isopropyl alcohol were used to clean the sample surface before testing. During the damage test, the laser output wavelength was set to 3.8 µm, the pulse width was 25–35 ns, and the mode was TEM00. The laser energy was Gaussian-distributed, and the laser had to be warmed up for at least 15 min before the official test to ensure the stability of the output. The results of the damage threshold test are presented in Figure 7.

Figure 7. Statistical plots of zero-damage thresholds for samples with different processing techniquesand for samples after etching. A-C are bonnet-polished samples, D-F are (MP-polished samplesand G-I are RF-polished samples. B, E, and I are dry-etched samples. A, D, and G are wet-etchedsamples.C,F,and I are wet-etched samples.

Figure 8 shows the morphology of the damage crater observed with a scanning electron microscope after the damage test. The size of the damage pits is marked in the figure. Our observation indicates that the damage occurred on the front surface of the sample, which is the incident surface of the laser. By comparing the damage morphology after different etching processes, we found that the optical element in the center of the laser spot underwent melting, followed by the production of solid particles around the melting area due to the process of melting and cooling after high-temperature treatment. The outermost edges also produced some spattering of the material during the laser action. The size and depth of the damage pits were significantly smaller in the etched sample than in the unetched sample. In summary, the damage is mainly due to the thermal melting phenomenon caused by the temperature in the center of the optical element during the laser-loading process, which exceeds the melting point of the material itself.

Figure 8. Damage crater morphology of bonnet-polished samples. (a) primary sam ple; (b ,c) are the samples after dry etching and wet etching, respectively.

4.Conclusions

Through the implementation of a laser-scattering test and the photothermal weakabsorption technique, we have effectively established a correlation between damage precur.sors and the resistance of materials to laser damage. In addition, we employed photothermal absorption level as a crucial parameter to determine the damage resistance thresholdof optical elements. In this study, we investigated the damage precursors of samples withdifferent processing techniques, using the laser-scattering test and photothermal weakabsorption test to compare the characteristics of different processing techniques. Followingthat, we utilized dry etching and wet etching techniques to effectively eliminate the damageprecursors. Subsequently, these precursors were characterized using a range of testingtechniques. We successfully obtained optimal damage precursor removal me thods for polishing different types of single-crystal silicon components and determined the relationshipbetween the effects of different damage precursor removal methods on damage perfor.mance. These findings have the potential to significantly enhance the damage threshold ofoptical components.

上一篇: 过渡金属二硫属化物外延生长的晶片材料

下一篇: 促进二维材料的氟化和蚀刻