Abstract—Silicon ring resonators on SOI substrates are well known and widely studied. They are commonly used in datacom and high-performance computing for wavelength multiplexing and spectral filters. They can be tuned to the desired frequency with resistive heaters, which is the primary power budget of the device. In this work, the impact of backside cavities etched in the bulk silicon of SOI substrates below ring resonators is studied. Simulations show that those backside cavities improve significantly heat confinement and minimizes heat losses usually due to conduction in the Si substrate. Backside cavities have been successfully etched in the bulk of the SOI substrate to improve heat trapping within the silicon rings. The etching process is compatible with the standard silicon photonics interposer process flow.

Power consumption studies have been performed with a reference ring resonator on SOI and ring resonators with different backside cavity diameters. These results will be discussed with respect to the backside cavity opening. A 72% power consumption reduction for a 10 µm diameter ring resonator on SOI has been achieved with a backside opening of 100 µm deep and 40µm diameter. The cavities opening did not impact the optical ring performances.

I. INTRODUCTION

Silicon photonics propose an interesting path for increasing bandwidths for high speed communications in datacenter and high-performance computing applications. This technology can leverage the technical know-how of traditional CMOS foundries to make performant and reliable systems. A common optical solution in the field of silicon photonics is to use wavelength multiplexing to increase bandwidths of transceivers and optical networks on chips (ONoC) communication. In this framework, multiple wavelengths of infrared light are injected in a single waveguide. The multiple wavelengths are then demultiplexed at the point of use, thanks to a spectral filter, such as a ring resonator (RR).

As introduced in , the thermal tuning consumes half of the total power of the whole transceiver system. This work aims to reduce this thermal tuning power consumption by isolating the silicon ring resonator to lower heat loss due to conduction in the bulk Si of SOI substrates. In this letter, simulations are first conducted to evaluate the impact of backside cavities on heaters power consumption. In a second part, silicon photonics technology and cavity process flow will be detailed to fabricate the micro-ring resonators. The testing methodology will be then described. Finally, the impact of backside cavities on the tuning power and on the dynamics will be discussed.

II. FEM SIMULATION

In this part, the effect of a cavity on the backside of the substrate is studied. A 3D model of a RR with appropriate dimensions id created using COMSOL software. A power density is applied at the center of the ring such that the temperature inside the ring reached 100°C. This is repeated with three different cavity diameters: 25, 30 and 40 µm. For each cavity diameter, the power density is adjusted to match the temperature of 100°C in the ring. This power density is finally converted to power by multiplying the power density by the volume of the heater element.

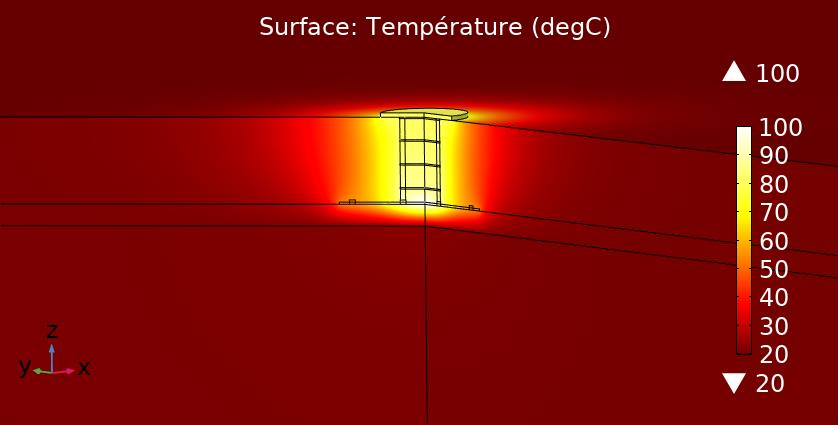

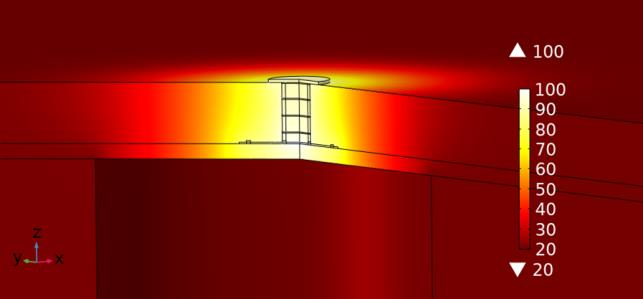

As shown on figure N, the presence of the cavity changes the temperature field. The temperature is more uniform in the ring region. The heat also diffuses farther away from the ring, as illustrated in figure X, which shows the temperature along the ring radius. The temperature in the case of a ring without a backside cavity (in black) reaches equilibrium at 10 µm from the center (i.e. 2 radii), while backside cavities increase this distance up to 25 µm, or 5 radii. In most real-world designs, the rings are spaced out by more than 25 µm, therefore the thermal cross talk between adjacent rings can be neglected.

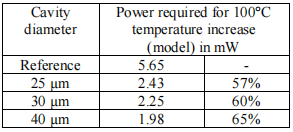

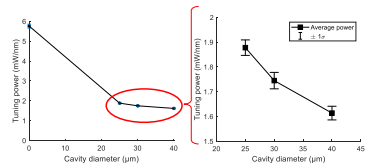

The power required to reach 100°C inside the ring for the three cavities and a reference without cavity is presented in table 1. The simulations show that the power required can be reduced significantly, from 57% for the smaller cavity to 65% for the larger cavity.

Table 1: Power required for 100°C increase in model temperature with different cavity sizes

III. PROCESS

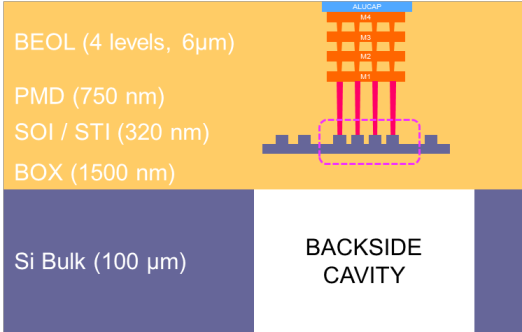

This work is based on STMicroelectronics 2nd generation Siphotonics process, using 300 mm SOI wafers with 1.5 µm buried oxide layer (BOX). The silicon RR of interest have a 10 µm diameter with heaters of doped silicon on the waveguide level, in the middle of the resonator. The heater module is composed of 4 strips of doped Si located on the waveguide level, as shown in the middle of the ring of Figure 3, with 4 rows of 2 rectangular marks. By supplying them a direct current, these resistors will heat up thanks to Joule effect, increasing the temperature in their vicinity. The waveguides used in our rings are in deep-rib configuration with a 50 nm slab. The rings are connected thanks to four metal levels and Al pads for testing. A schematic cross section of the wafer can be seen in Figure 4.

Figure 3: Optical top view of microring (purple and yellow) and etched cavities footprint to scale (green – 25 µm, red – 30 µm and blue – 40 µm).

Figure 4: Schematic cross section of the stack at the end of process (not to scale)

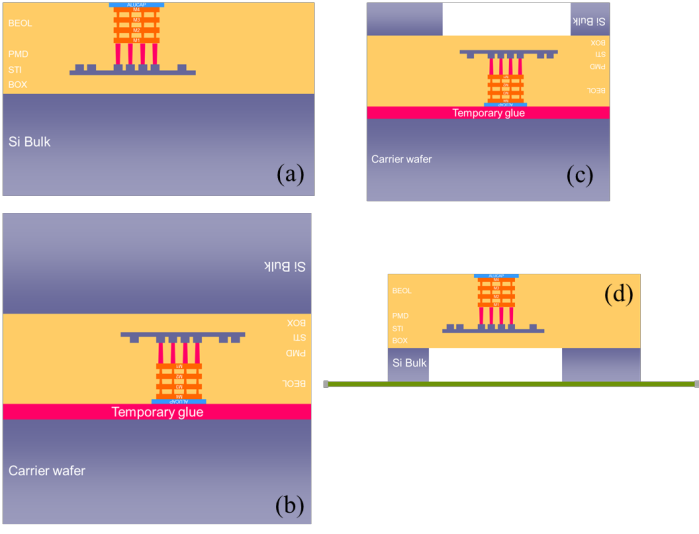

After this standard photonic process (Figure 5 a), the front side of the wafers are bonded on carrier wafers with temporary glue (Figure 5 b), and thinned down to 100 µm. This thickness is compatible with the height of TSV-Mid process (10×100 µm) that will be integrated in similar wafers in order to create photonic interposers. The cavity patterning alignment is done on front side with Metal 1 marks thanks to a dedicated infrared Canon stepper. Marks have been chosen at Metal 1 level to insure a strong infrared contrast through the thinned silicon substrate from the wafer backside. Our alignment approach grants an accuracy below 1 µm between the waveguide level and the backside cavity. An 8 µm thick TCIR photoresist has been selected for the backside cavity lithography thanks to high etching selectivity with Si.

Figure 5: Process flow of the backside cavity

After the backside etching (Figure 5 c), the thin wafer is debonded from its temporary carrier using an EVG820 tool to a handling tape and frame compatible with the prober station (Figure 5 d). In the case of TSV-mid process integration for photonic interposers, processed wafers could follow the standard backside process route (BRDL, organic passivation and under ball metallization). However, in this study no TSVs are implemented in the tested wafers.

IV. TESTS

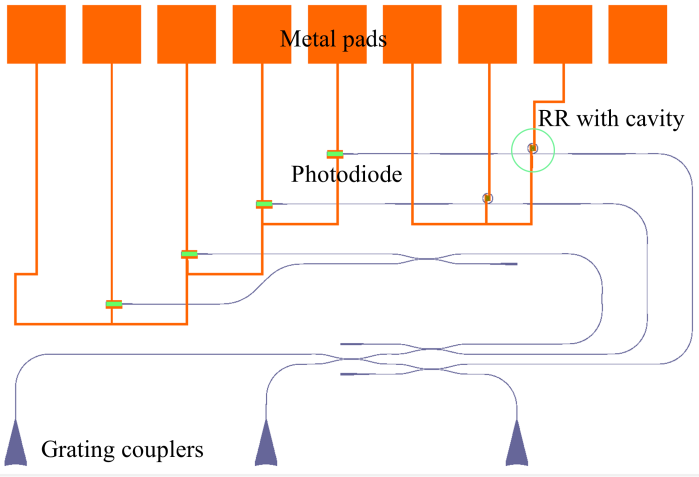

To measure the thermal tuning efficiency of the ring resonators, 4 test structures have been designed. Figure 7 shows the layout of the structure. RR structures are then processed with 25, 30 and 40 µm cavity diameter opening and one with no opening.

Figure 7:Test structure layout

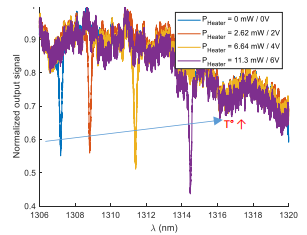

Optical fibers are placed on top of grating couplers to infect light in the optical circuit. Fiber alignment is performed at each die using light exiting the circuit on the rightmost grating coupler. For this experiment, only the top row is of interest. Light passes through a ring resonator with (or without) backside cavities. The resonance peaks are be caused by destructive interference, resulting in an extinction peak in the output spectral response. Output light is then collected and converted to electrical current using a germanium p-i-n photodiode. The output current from the photodiode is then amplified with a trans-impedance amplifier (TIA) before acquisition. The input laser is tuned so that the spectral response goes from 1280 to 1340 nm with a step of 2 pm to have adequate resolution on the resonance peaks. The resonant wavelength closest to 1310 nm without heating is extracted for each of the 4 heater powers, and a linear fit yields the tuning efficiency. A total of 15 samples are measured for each cavity on the same wafer to reduce the variability inherent to the fabrication process.

Figure 8: Evolution of the resonance peak with different applied heater powers of a 10-µm diameter RR with a 40-µm backside opening.

V. RESULTS AND DISCUSSION

The impact of the cavities is deduced by comparing the tuning powers of the rings with different cavity diameters to a reference ring without cavity. Table 2 summarizes the average tuning power and their standard deviation for the different cavities and for the reference ring, as well as the relative improvement of the cavity on the tuning power compared to the reference ring.

The measurements summarized in Figure 9 are in agreement with the simulations and show a vast reduction in the ring tuning power. For the 40 µm-cavity, the reduction is as important as 72%, while it is at 67% for the smaller 25 µmcavity. This improvement can be attributed to a better heat confinement in the ring and lower heat losses via conduction from the substrate acting as a heatsink, as suggested by the FEM simulations.

Figure 9: Tuning power evolution with cavity diameter

VII. CONCLUSION

In this work, backside cavities have been successfully processed on silicon photonics wafers and evaluated. The developed process flow exhibits no incompatibly with a standard silicon photonics interposer process flow. These cavities allow to significantly lower power consumption for thermal tuning without undesirable changes in the ring behavior. It is shown that a 100 µm deep, 25 µm diameter cavity on a 10 µm ring reduces the tuning power needed by 67%, without changing the behavior of the ring, while a 40 µm cavity reduces the tuning power by 72%.

The Si/SiO2 selectivity of the etching process allows multiple cavity diameters to be etched in a single step, allowing flexibility in the design of the photonic front end and minimal engineering for the realization of the backside cavity.

下一篇: 高通量在线硅晶圆检测中的定量剪切应力成像