ABSTRACT

This study explores the growth and structural characteristics of Nd2O3 layers on virtual germanium-rich SiGe substrates on Si(111). We focus on the emergence of the hexagonal phase depending on the stoichiometry of the virtual substrate. X-ray diffraction measurements reveal a hexagonal phase when Nd2O3 is grown directly on Si(111), while growth on Ge leads to a cubic oxide structure. On SiGe layers, the growth of the oxide results in a mixed phase containing hexagonal and cubic regions, regardless of the Ge content. The cubic structure grown on virtual Ge substrates exhibits strong tensile strain, while layers grown on SiGe layers show no strain. In situ growth control via electron diffraction shows a dependence of the oxide structure of the surface reconstruction of the virtual substrate. Growth on a 7x7 reconstruction leads to hexagonal parts on Si-based substrates, while growth on c(2x8) results in cubic oxide growth on Ge. Furthermore, oxide layers grown on virtual SiGe substrates form an interfacial silicate layer. The thickness of the interfacial layer is influenced by the Si content and the structure of the oxide layer enabling oxygen diffusion pathways.

I. INTRODUCTION

The integration of materials like germanium and silicon germanium on silicon is attractive for several reasons. These materials not only enable high-mobility channels with very high Ge content while mitigating parasitic effects like drain-induced barrier lowering but also the incorporation of optical devices in Si complementary metal-oxide-semiconductor (CMOS) devices.Ge and germanium-rich Si1-xGex layers are known to have high intrinsic electron mobilities and especially high hole mobilities, making them suitable for CMOS devices.However, while p-type Ge-based devices have performed reasonably well, especially n-type Ge-based devices fall short of expectations.

The successful integration of Ge-based devices still faces substantial challenges. These challenges involve issues at the Ge/metal interface, which suffers from Fermi level pinning, and more critically, the poor interface quality between oxides and SiGe or Ge layers. Despite the initially lower number of dangling bonds at the interface in the Ge/GeO2 system compared to the Si/SiO2 system, the inability to passivate Ge dangling bonds with hydrogen has rendered interface control at Ge interfaces quite difficult. These unpassivated Ge dangling bonds contribute to the high density of interface states, degrading device performances.Even in SiGe-based devices, the high density of interface states is associated with undesired GeOx formation at the high-k oxide (e.g., HfO2) and SiGe interface.

II. EXPERIMENTAL

All heterostructures were grown on 100 mm diameter p-doped (0.5–0.75 Ω cm) Si(111)-wafers. Prior to layer growth in a DCA S1000 molecular beam epitaxy (MBE) cluster system, the samples underwent ex situ cleaning by a UV/ozone treatment coupled with a diluted HF etch step (0.2%). The deposition chamber of the MBE multi-chamber system reaches a base pressure of 1.3x10-10mbar. Ge, Si, and granular Nd2O3 were evaporated by electron beams and carbon was sublimated from a pyrolytic graphite filament in a SuKo-65 from Dr. Eberl MBE-Komponenten. To maintain a stable oxygen partial pressure, pure oxygen (6N purity) was introduced using a piezo leakage valve. The growth process was monitored in situ through reflection high-energy electron diffraction (RHEED) using a RHEED 35 from STAIB Instruments, which allows for realtime observation of the surface reconstruction and layer morphology during growth.

III. RESULTS

A. RHEED

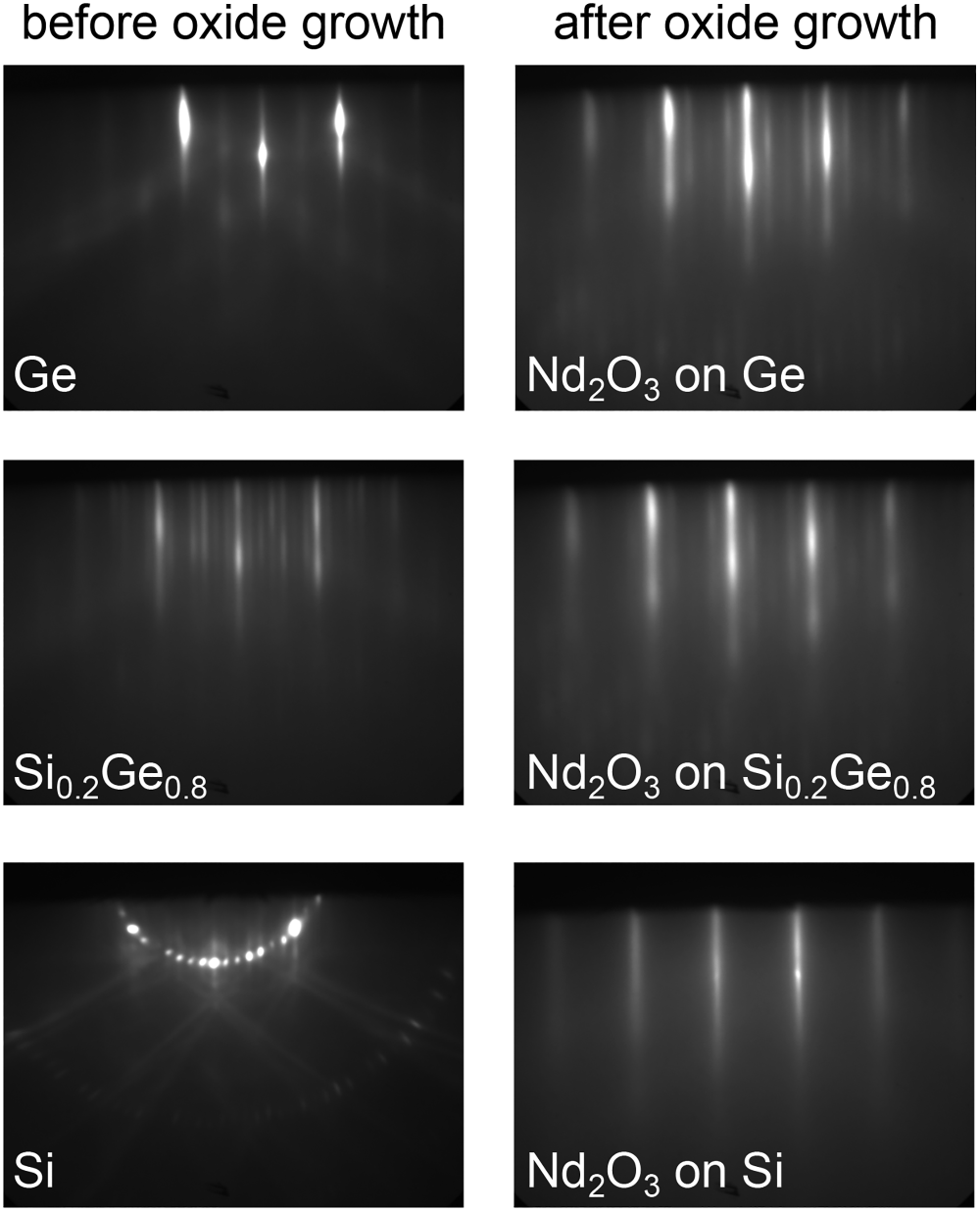

After growth of the Ge-rich Si1 xGex layers as virtual substrates, the in situ RHEED control shows a smooth surface with all layers displaying a c(2 x 8) surface reconstruction.Subsequent annealing to 400℃ results in a 7x 7 surface reconstruction for a Ge content of 0.55 <x<1. Ge layers exhibit a c(2x8) reconstruction just before transitioning to a 1 x1 reconstruction, as described in Ref. This transition is indicated by the weakening of the intensity of the substreaks. The Si surface shows a 7x7 surface reconstruction as expected after thermal preparation. The RHEED patterns before oxide growth are depicted in Fig. 1 on the left-hand side, while patterns after oxide growth are presented on the right-hand side for one representative sample from each substrate. The streaky patterns indicate a smooth surface, which is confirmed by AFM measurements revealing a root-mean-square surface roughness below 0.6 nm for all samples.

FIG. 1. In situ RHEED control of three exemplary samples before and after oxide growth in the <110>direction. Before oxide growth, the Si(111) and SiGe surface exhibit a 7x7 surface reconstruction, while the Ge layer shows a c(2 x8) reconstruction. After oxide growth, the RHEED pattern of the oxide grown on Ge and SiGe shows three additional substreaks, while the oxide layer grown directly on Si shows no substreaks.

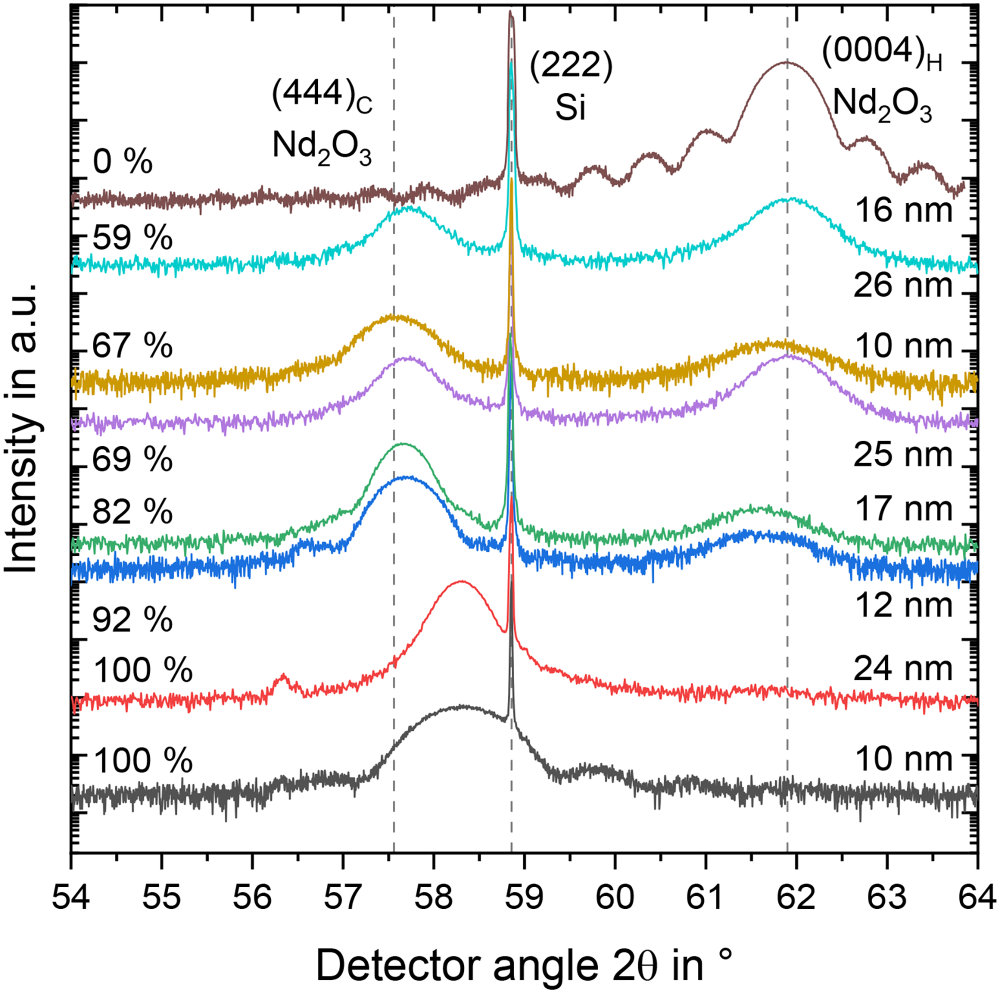

We conducted an in-depth analysis of the crystallographic phase of the Nd2O3 layers using XRD measurements. The results of our symmetrical θ=2θ measurements are shown in Fig. 2. Notably, the Nd2O3 layer grown directly on Si(111) exhibits a hexagonal structure while growth on Ge results in a cubic structure. Oxide layers grown on SiGe show a mixed phase containing both cubic and hexagonal parts, regardless of their layer thickness. Furthermore, it is evident that the oxide layers grown on Ge exhibit strong tensile strain, while the hexagonal phase grown on Si(111) shows no indication of strain. Growth on SiGe results in relaxation of tensile strain in the cubic phase, even at very high Ge contents of x>0.9.

FIG. 2.

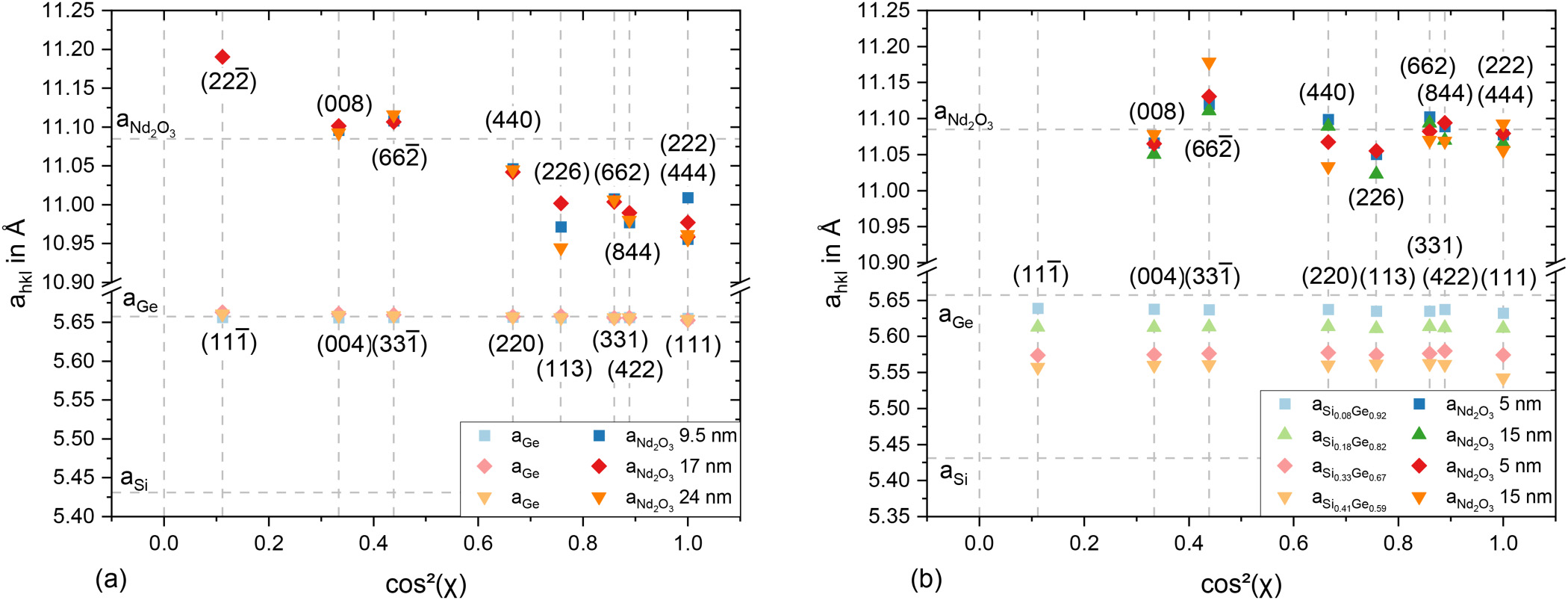

Figure 3(a) reveals fully relaxed virtual Ge substrates, while the oxide layers exhibit substantial tensile strain, regardless of the layer thickness. In contrast, the results for oxide layers grown on SiGe, as shown in Fig. 3(b), indicate almost fully relaxed oxide layers, with the virtual substrates also remaining in a fully relaxed state.

FIG.3.

At this point it appears like the Si content at the interface plays a crucial role in the growth of oxide layers, as the hexagonal content in the oxide layer increases with increasing Si content in the virtual substrate. While there is a slight increase in the hexagonal-to-cubic ratio concerning increasing oxide layer thickness, the Si content dependency is much more prominent. This suggests that the growth of Nd2O3, like Gd2O3, 34 strongly depends on the initial nucleation processes, which we need to examine further regarding the interface and silicate formation. It is worth noting that no evidence of the amorphous interfacial layer was observed during growth using RHEED, suggesting that the formation of this layer occurs during subsequent growth.

Early investigations suggested Si diffusion from the substrate into the RE oxide, followed by a reaction, as the primary process for silicate layer formation.However, subsequent research revealed that annealing of capped Si/REO structures prevents silicate formation, promoting a different mechanism where diffused oxygen reacts with the Si substrate, resulting in Si–O molecule diffusion and reaction with the REO to form silicates.The cubic structure of REO is inherently defective, with one-fourth of the sites in the anion sublattice remaining unoccupied. Thus, this structure exhibits relatively unimpeded pathways along the 111 h i directions for the migration of oxygen through the lattice.

In summary, our study of Nd2O3 growth on virtual germanium-rich Si1-xGex substrates with a Ge content of 055<x<1 and Si(111) has revealed insights into the dependence of crystalline phases and interface processes of the oxide layers on various substrates. Our analysis showed that Nd2O3 grown directly on Si(111) exhibits a hexagonal structure, while growth on Ge leads to a cubic structure. On Si1-xGex substrates, a mixed phase of cubic and hexagonal parts is observed, regardless of the Ge content. Oxide layers grown on Ge exhibit strong tensile strain, while layers with hexagonal parts show no strain. XPS combined with TEM and EDS analysis indicate the formation of an interfacial silicate layer on SiGe substrates, which increases in thickness as the Ge content decreases. We attribute the silicate formation to the high diffusion rate of oxygen through cubic Nd2O3, as well as Si diffusion toward the interface with the virtual substrate. The emergence of the hexagonal phase in the oxide layers might be influenced by the surface reconstruction of the substrate. Samples with hexagonal oxide regions show a 7X7 surface reconstruction before oxide growth, while purely cubic oxide layers are grown on surfaces with a c(2X8) surface reconstruction. In conclusion, our investigation highlights the interplay of strain, diffusion processes, and substrate surface reconstruction in the growth of Nd2O3 on silicon-based substrates. It provides valuable information on structural properties and silicate formation mechanisms, although the exact mechanisms of the hexagonal phase’s emergence require further study.

上一篇: 溅射沉积Ga2O3薄膜的微结构和光学特性

下一篇: 通过边缘加固实现独立超薄硅片和太阳能电池