ABSTRACT.

A great deal of interest is directed nowadays towards the development of innovative technologies in the field of quantum information and quantum computing, with emphasis on obtaining reliable qubits as building blocks. The realization of highly stable, controllable and accessible hole spin qubits is strongly dependent on the quality of the materials hosting them. Ultra-clean germanium/silicon-germanium heterostructures have been predicted and proven to be promising candidates and due to their large scalability potential, they are opening the door towards the development of realistic and reliable solid state, all-electric, silicon-based quantum computers. In order to obtain ultra-clean germanium/silicon-germanium heterostructures in a reverse grading approach, the understanding and control over the growth of Ge virtual substrates and thin films is key. Here, we present a detailed study on the growth kinetics, morphology, and crystal quality of Ge thin films grown via chemical vapor deposition by investigating the effects of growth temperature, partial pressure of the precursor gas and the use of Ar or H2 atmosphere. The presence of carrier gases catalyzes the deposition rate and induces a smoothening on the surfaces of films grown at low temperatures. We investigated the surface roughness and threading dislocation density as a function of deposition temperature, partial pressure and gas mixture. Ge thin films deposited by diluting GeH4 in Ar or H2 were employed as virtual substrates for the growth of full Ge/SiGe QW heterostructures. Their defect density was analyzed and their electric transport properties were characterized via Hall measurements. Similar results were obtained for both carrier gases used.

I. INTRODUCTION

In the last decade, group-IV materials, and in particular Germanium (Ge), have gained renewed attention due to their excellent electrical and optical properties, which together with their compatibility with well-established CMOS manufacturing technology, allow the realization of a wide range of new devices. In particular, Germanium/Silicon-Germanium (Ge/SiGe) heterostructures are appealing platforms for photonics, microelectronics and quantum computing. In the frame of quantum information, they were developed as a successful planar technology able to combine low disorder, fast qubit driving and scalability as well as compatibility with the widespread micro-fabrication techniques employed in the integrated circuitry industry. Under electrostatic gating, undoped Ge/SiGe quantum wells (QWs) accumulate holes with very high mobility, light effective mass, and tunable spin-orbit interaction allowing fast and fully electrical control of the spin qubits. Integration over a common platform, requires a careful choice of materials. Employing Ge wafers as substrates for the heterostructure growth would be the first logical direction to follow, nonetheless, they are more expensive and less pure and durable than their silicon counterparts.

In this work, we present a comprehensive study of the effect of the deposition conditions of Ge films on silicon substrate. Namely, we have investigated the effect of growth temperature, partial pressure of the precursor gas, and dilution in Ar or H2 atmosphere on the growth kinetics, surface roughness, and defect density. Moreover, we demonstrated the performance of these Ge layers as QWs and virtual substrates via Hall effect measurements of Ge/SiGe stacks grown at selected conditions resulting from this study, and hence their applicability in highly scalable, compatible and performant spin-hole qubit planar devices.

II. EXPERIMENTAL

All the layers within this study were grown by a cold wall CVD using a PlasmaPro 100 Nanofab reactor equipped with a showerhead (Oxford Instruments, base pressure < 0.5 mTorr), commercial Germane as a gaseous precursor (GeH4, Pangas, 99.999%) and Argon and Hydrogen (Ar, H2, Pangas, 99.999%) as carrier gases or Silane (SiH4, Pangas 99.999%) for depositing Sibased layers in ancillary Ge/SiGe test heterostructures. Prior to growth, the Si (100) substrates (float zone, undoped, resistivity > 10’000 ohm*cm) were cleaned through a one-minute dip in 2% HF aqueous solution followed by a rinse in DI water and IPA to remove the native oxide. The investigation was performed in three steps: firstly, the growth rate of Ge thin films was studied under different conditions of precursor partial pressure, temperature, and dilution with a carrier gas. The CVD system allowed to control the flow rates and the total pressure independently – via mass flow controllers (MFCs) and an automatic valve coupled to a pressure sensor – allowing to reproducibly establish the desired partial pressure of each gas within a range of 0.1-20 Torr. Each MFC was calibrated for the specific precursor or carrier gas employed, allowing a maximum flow of 50 sccm for GeH4, 2000 sccm for Ar, 2000 sccm for H2, and 200 sccm for SiH4.The temperature was controlled by means of a hot plate coupled to a thermocouple located under the sample, in the range of 300-600 °C. The thicknesses of the deposited Ge thin films were determined via cross-section Scanning Electron Microscopy (SEM), which together with the growth time were used to calculate the growth rates. Secondly, the morphology of the films grown with different carrier gases was characterized through Atomic Force Microscopy (AFM) in regards of surface roughness. Thirdly, full Ge/SiGe QW structures were grown on top of Ge virtual substrates obtained via Ar- and H- assisted growth. Lamellas of the QW stacks were fabricated through Focused Ion Beam (FIB) and imaged via Transmission Electron 6 Microscopy (TEM) to estimate the defect density in the Ge virtual substrates. The threading dislocation density (TDD) was quantitatively evaluated by means of Etch Pit Count, employing a mixture composed of HF 2.3%:HNO3 50%:CH3COOH 100% in a volume ratio 10:2:2, plus 60 mg of I2 dissolved per each 52 ml of mixture, and further diluted with DI water in a volume ratio 3:1. The samples were etched in the aforementioned diluted, acid and iodic mixture – adapted from– for 2 minutes at room temperature, revealing etch pits capping the threading dislocations, distinguishable and quantifiable in an area basis by means of SEM. Areas of 30 x 30 µm2 were defined all over the sample surface and TDD was calculated as a statistical average of the results obtained by analysing 30 images per sample. Hall-effect measurements were carried out to determine the effect of different virtual substrates on the performance of the heterostructures in terms of electronic transport properties.

III. RESULTS

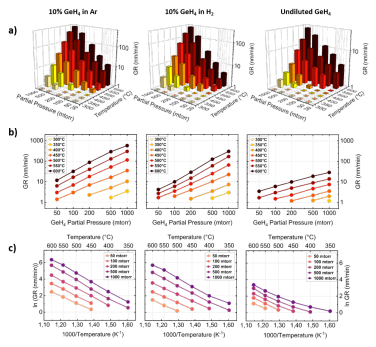

To determine the influence of precursor partial pressure and temperature on the growth rate of Ge thin films, the cross section of the films was measured via SEM. The films were grown on 1 x 1 cm2 Si chips, by using total flows of 200 sccm for 10% GeH4 diluted in Ar or H2 and 50 sccm for undiluted GeH4. Their thickness was measured in 4 different regions, moving in steps of 2.5 mm from one side to the other, in order to account for eventual non-uniformities in the layers. Variations in thickness observed for different regions of the wafers were limited to ±2 nm for thicknesses up to 500 nm, ±5 nm for thicknesses in the range 500 nm to 2 µm, and ±10 nm for thicknesses over 2 µm. Figure 1 shows the growth rate dependence on precursor partial pressure and temperature for 10% GeH4 diluted in Ar, 10% GeH4 diluted in H2, and undiluted GeH4. A linear increase with GeH4 partial pressure and an exponential one with temperature for the growth rate can be qualitatively observed in Figure 1(a) for the three cases. The linear dependence on the precursor partial pressure can be assessed more clearly from Figure 1(b). The average slopes are 1.11 ± 0.13 mTorr min nm-1 , 1.21 ± 0.20 mTorr min nm-1 and 0.68 ± 0.02 mTorr min nm-1 for 10% GeH4 in Ar, 10% GeH4 in H2, and undiluted GeH4, respectively. The increase in deposition rate is explained by the higher impingement rate per unit area of molecules, which is linearly dependent on the pressure. The exponential dependence on the growth temperature is highlighted through the Arrhenius plots (Figure 1(c)), which provide an activation energy for the reaction of 87.34 ± 6.78 kJ mol-1 , 80.19 ± 5.94 kJ mol-1 and 81.33 ± 9.28 kJ mol-1 for 10% GeH4 in Ar, 10% GeH4 in H2 and undiluted GeH4, respectively. These values of activation energy are consistent with a thermally activated process, dominated by diffusion and adsorption from the gas phase on the surface, and fall within the range of values reported in literature for similar reactors and process conditions (35 - 130 kJ mol-1 ). A further trend can be identified in Figure 1(a)-(c), related to the presence and type of carrier gas mixed with GeH4. Under the same conditions of reactor temperature and GeH4 partial pressure, the growth rate is higher when employing a carrier gas (Ar or H2) compared to the undiluted GeH4 case, and a further enhancement occurs when using Ar instead of H2. This behavior is explained in terms of changes in the heat transport to and from the sample upon addition of carrier gases. Adding carrier gases leads to a lower average heat capacity of the gaseous mixture, which leads to a decreased heat loss to the gas phase. Furthermore, the addition of a carrier gas with its own heat capacity and partial pressure contributes to the heat transfer of the gas localized in the micro-gaps between the sample and the hotplate, which due to the small scale is well into the free molecular regime.

Fig1

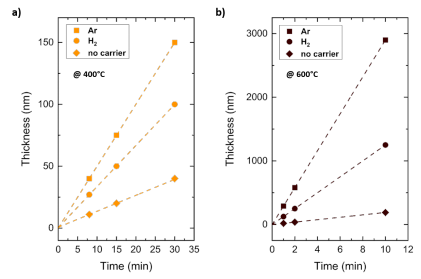

In order to investigate the potential presence of a delay between the exposure to gas precursors and actual growth of the Ge films (a so-called nucleation time), the variation of the film thickness with time was evaluated for the three precursor gas mixtures at low (400°C) and high (600°C) temperature by keeping the GeH4 partial pressure fixed at 500 mTorr. Figure 2 shows the film thickness dependence on the growth time. Linear fits of the data intercept the origin of the reference system, excluding any significant nucleation time.

Figure 2. Film thickness as function of deposition time for Ge TFs deposited from 10% GeH4 in Ar, 10% GeH4 in H2 and undiluted GeH4 at (a) 400°C and (b) 600°C at a constant 500 mTorr GeH4 partial pressure. Dotted lines represent a linear fit of the data sets. Please notice that the error bars accounting for the standard deviation of the data set are plotted, but not visible due to the small values for the errors.

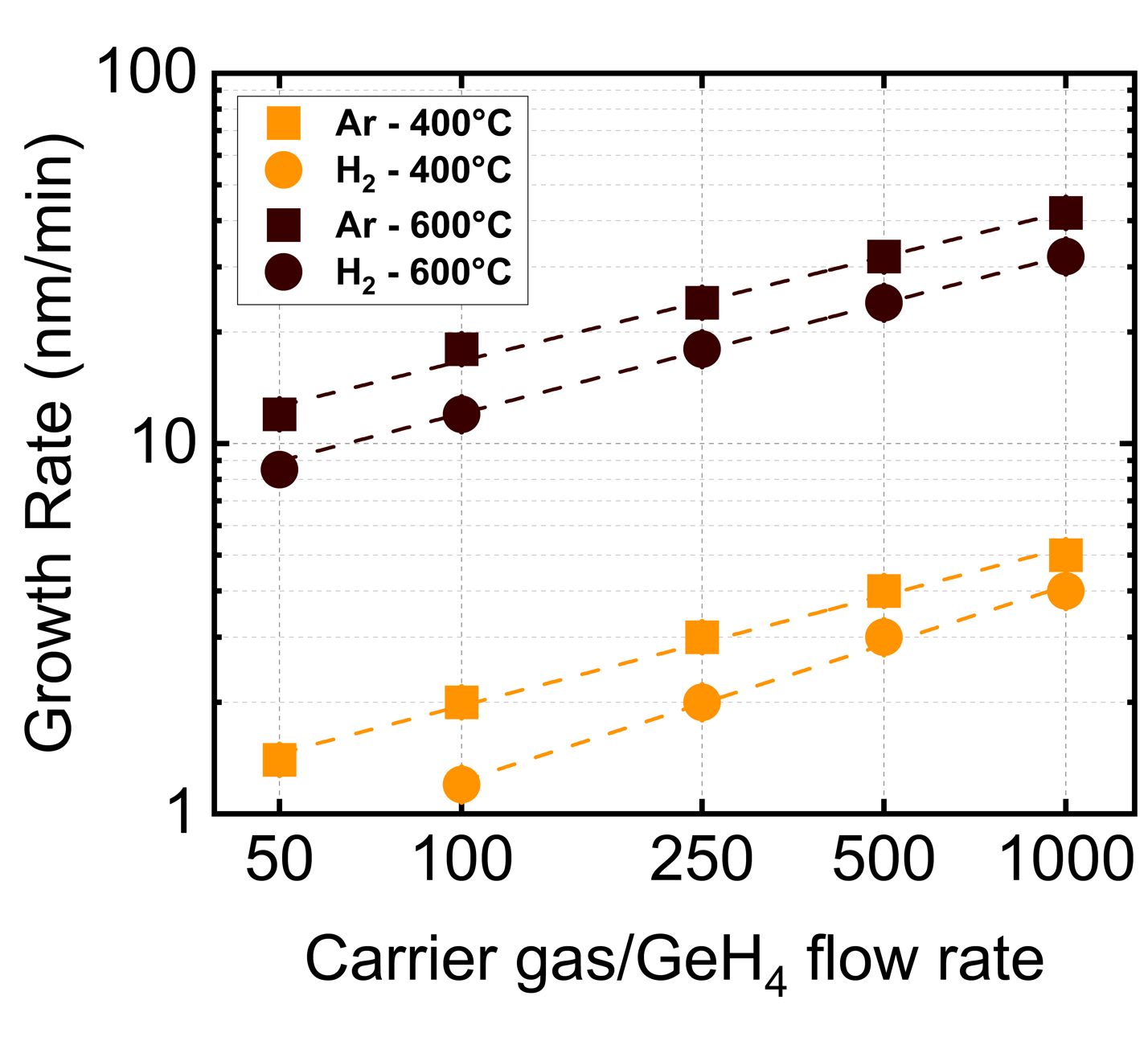

To further investigate the effect of the dilution of GeH4 in a carrier gas, we studied the variations in growth rate as function of the dilution flow rate, which is defined as the flow rate of the carrier gas (either H2 or Ar) divided by the flow rate of the precursor gas (i.e. GeH4), as shown in Figure 3. These experiments were performed at low (400 °C) and high (600 °C) temperature while keeping the GeH4 pressure at 30 mTorr.

Figure 3. Growth rate dependence of Ge TFs on Ar and H2 to GeH4 flow rate at a constant 30 mTorr GeH4 partial pressure at 400°C and 600°C. Dotted lines represent a linear fit of the data sets. Please notice that the error bars accounting for the standard deviation of the data set are plotted, but not visible due to the small values for the errors.

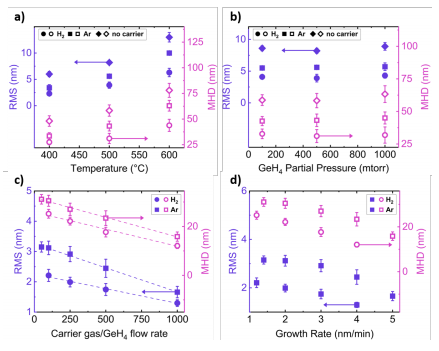

In order to study the morphology and roughness of the films and their dependence on the deposition conditions, we performed AFM measurements on 100 nm thick Ge films deposited from 10% GeH4 in Ar, 10% GeH4 in H2 and undiluted GeH4. At temperatures as low as 400°C, the films are smooth, with root mean square (RMS) roughness and maximum height difference (MHD) values below 4 nm and 35 nm, respectively, when using a carrier gas. Both roughness parameters increase when using higher temperatures, as a result of the nucleation of a larger number of Ge islands (Figure 4(a)). No major difference in RMS and MHD is instead observed when varying the partial pressure of the precursor gas (Figure 4(b)). In both cases , the roughness of the films improves when employing a carrier gas compared to the undiluted case.

Fig4

IV. DISCUSSION

Within this study, the growth kinetics of Ge thin films were studied under different conditions of temperature (300 – 600 °C), precursor partial pressure (GeH4 at 50 – 1000 mTorr), and carrier gas (Ar, H2 or undiluted). No growth was observed below 350°C, since the temperature is too low to overcome the activation energy for the reaction. The presence of a carrier gas is shown to catalyze the deposition rate, by thermally enhancing the dissociation rate of gas molecules, and the effect becomes more prominent when the ratio of carrier gas to GeH4 is increased. No delay in deposition was observed in any of the considered cases, discarding the presence of any significant nucleation time. Low temperatures (~ 400°C) and dilution of GeH4 in Ar or H2 induce the formation of monolayer islands that coalesce forming a full 2D layer typical of a Frank-van der Merwe (layer-by-layer) growth mode, keeping the surface smooth. The crystalline and surface morphological properties of the thin films were studied by Raman, XRD, SAED, EPC, and AFM measurements. All the samples are single crystalline, regardless of the deposition conditions, while films grown at high temperature exhibit a higher degree of relaxation. The TDD decreases with increasing the deposition temperature, while it is independent of GeH4 partial pressure, and when using a carrier gas. As for the surface morphology, while the RMS and MHD decrease with the temperature and are independent of GeH4 partial pressure, growth of high temperature Ge films onto low temperature ones ensures RMS values below 1 nm.

V. CONCLUSIONS

A comprehensive study on the growth kinetics and morphology of Ge thin films together with electronic transport properties of Ge/SiGe heterostructures was performed for different precursor gases. Growth kinetics were characterized as a function of the growth parameters and precursor gases, showing expected linear and exponential trends with gas partial pressure and temperature respectively, and a significant enhancement when diluting GeH4 in Ar or H2 atmosphere. Carrier gases thermally boost the surface diffusion, hindering the formation of islands and leading to smooth layers for the layers thicknesses here considered. TDD of the Ge virtual substrates grown by two-steps temperature is in the order of 109cm-2 regardless of the carrier gas employed. The steepness of the interfaces between the QW and the barriers and the percolation density are not affected by the choice of the carrier gas employed in the growth of the virtual substrate. Relevant improvements in the mobility values can be expected by reducing the TDD in the virtual substrate by performing cyclic thermal annealing. Finally, a further improvement of the transport and spin properties can be expected by implementing isotopically purified gas precursors.

上一篇: 通过边缘加固实现独立超薄硅片和太阳能电池

下一篇: 半导体湿法刻蚀概述