Abstract. Bodies made from elastically stiff material usually bind very weakly unless the surfaces are flat and extremely smooth. In direct wafer bonding flat surfaces bind by capillary bridges and by the van der Waals interaction, which act between all solid objects. Here we study the dependency of the work of adhesion on the humidity and surface roughness in hydrophilic direct wafer bonding. We show that the long-wavelength roughness (usually denoted waviness) has a negligible influence on the strength of wafer bonding (the work of adhesion) from the menisci that form from capillary condensation of water vapor.

Two neutral, elastically stiff and dry solid objects usually do not adhere to each other. This is a result of the surface roughness which reduces the area of real contact, where solid-solid adhesion can occur, to a very small fraction of the apparent area of contact. If a loading pressure is applied to increase this real contact area, the surface asperities are deformed storing up elastic energy at the interface, which is then given back when the loading pressure is released, resulting, in most cases, in a negligible adhesive force. For extremely smooth surfaces (i.e., root-mean-square (rms) roughness 1 nm), however, adhesion can be observed even for elastically stiff solids.

Here, we consider the case of hydrophilic direct wafer bonding, where adhesion occurs between the two surfaces, usually silicon wafers covered by thin SiO2 oxide layers or silica glass surfaces (amorphous SiO2). This process is initiated by capillary condensation of water vapor in the small gap between the surfaces that generates a sufficient capillary adhesion force to overcome the elastic repulsion once the loading pressure exceeds a certain threshold, leading to “interfacial collapse” where the real area of solid-solid contact suddenly increases.

Wafer bonding is strongly influenced by surface roughness. In most studies the surface roughness is only characterized by the root-mean-square (rms) roughness amplitude hrms, which is usually determined by the most long wavelength roughness components. We show that for wafer bonding the long wavelength roughness is unimportant. This result from the the existence of a roll-off region in the surface roughness power spectrum, separating the short wavelength (≤ 60 nm) roughness from the longer (≥30 μm) waviness roughness. As a result, to determine (or control) the strength of wafer bonding, the roughness needs to be determined only over the length scales up to 0.1 μm. Also, we show that a better measure than the rms-roughness of the potential strength of wafer bonding is the elasticity integral defined by (4) below.

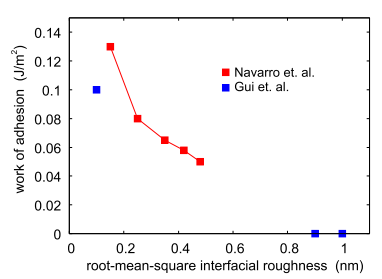

Figure 1 shows two sets of previously published experimental results that illustrate how the work of adhesion w0 is a function of the root-mean-square (rms) roughness amplitude. The red squares are from Ref. for the RH = 0.4 and was obtained from the bonding velocity assuming w ∝ v5/4. The blue squares are from Ref. (unknown RH) and was obtained using cantilever bending testing.

Fig. 1

Wafer bonding is a topic of high practical importance and of great scientific interest, and many papers have been published about wafer bonding. The strength of wafer bonding depends on the nature of the surface roughness which varies depending on the surface preparation method. Theory shows that the surface roughness on many length scales influence the work of adhesion, so it is not enough to characterize the surface with the rms roughness amplitude alone. For smooth surfaces like silicon wafers, the surface roughness on all relevant length scales can be studied using Atomic Force Microscopy (AFM). In addition, for strong bond formation the surfaces need to be cleaned and “activated”. For silicon wafers two surface activation methods have been used: exposure to oxygen plasma or wet chemical surface activation.

In the present study we use the surface roughness power spectrum obtained from atomic force microscopy (AFM) topography measurements on a Si(100) wafer. To obtain different magnitudes of the roughness, we scale the power spectrum with different prefactors. Note that since C(q) is quadratic in h(x) scaling the power spectrum with a factor s2 correspond to scaling the rms-roughness amplitude with a factors.

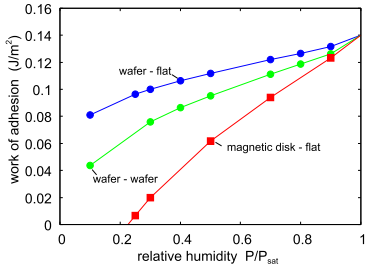

Figure 7 shows the work of adhesion as a function of the relative humidity RH = P/Psat (where P is the water partial pressure and Psat the saturated water partial pressure). Results are shown for the contact between two wafer surfaces (green symbols) and for the contact between a wafer surface and a perfectly flat counter surface (blue symbols). Also shown is the contact between the magnetic disk and a flat surface (red symbols).

Fig. 7

The breaking the adhesive bond between two surfaces is almost never uniform, but occurs instead by interfacial crack propagation. The onset of this crack propagation, however, is determined by the work of adhesion rather than the maximum pull-off stress during uniform separation. Since the interfacial collapse that occurs during the direct bonding between two wafers is just the reverse process of crack propagation, the work of adhesion is the most relevant parameter for the direct bonding process.

We have studied the influence of surface roughness and humidity on the work of adhesion for the case of hydrophilic wafer bonding. In agreement with experiments, we find that the surfaces with roughness greater than ∼ 1 nm rms amplitude (when measured over a surface area of order 1 μm×1 μm) will not bond under typical conditions unless the humidity is very close to the saturation level (i.e., relative humidity RH > 0.8). For any given surface roughness, the force needed to separate two solids with nominal flat surfaces takes a maximum for some relative humidity between 0 and 1 assuming the solids are separated with their surfaces parallel. Also, since bond breaking occurs non-uniformly in the form of interfacial crack propagation, the pull-off force is determined by the work of adhesion, which increases continuously with the humidity and reaches the value 2γ ≈ 0.14 J/m2 as RH → 1. We have shown that in the case of hydrophilic bonding of silicon wafers, the longwavelength roughness (usually denoted waviness) has a negligible influence on the strength of wafer bonding (the work of adhesion) due to capillary bridges.

上一篇: 通过芯片到晶圆混合键合实现多层芯片堆叠

下一篇: 从 HF 和 HCl清洁程序中获得的见解