Abstract.

The 3-D heterogeneous integration technology of microsystem is the best technical means to achieve higher integration, higher performance and higher working frequency of radio frequency (RF) electronic system.RF microsystem integration technology is categorized into three main types based on the packaging substrate:silicon-based,ceramic-based,and resin-based. In this work, the principle of RF microsystem integration technology is demonstrated in detail, and the process routes and characteristics of different packaging structures are clarified. Moreover, through the multi-dimensional comparison of different packaging structures, the application conditions of specific packaging structures are obtained. According to the comprehensive evaluation, the resin-based embedded chip package shows outstanding potentials in RF performance, integration capability, batch production capability and process cost. However, there are three shortcomings that limit its application in RF microsystems: Firstly, in terms of the universality of RF chips, metal grounding on the back of RF chips cannot be realized by this packaging, and special design of RF chips is required. At present, however, the universal chip with gold back grounding on the market cannot meet the requirements of the packaging process. Secondly, because of the high cost of customized chips, this packaging process is not suitable for small-scale production. Thirdly, the resin-based package does not have the sealing function, thus reliability of the product still needs to be verified. Ceramic-based RF microsystems do not require customized chips and have advantages in chip versatility compared to resin-based systems, with integration capabilities comparable to resin-based systems. However, its batch production capacity is much lower than resin based. In contrast, the silicon-based embedded chip package is as excellent as the resin-based products in chip versatility, RF performance, integration capability, batch production capability, etc., except that the manufacturing cost is high, and the yield should be effectively guaranteed in the manufacturing process. The conclusion provides a guidance for the future research of RF microsystem integration technology.

1.Introduction

Microelectronics and integrated technology are closely intertwined with the advancement of electronic products. Microelectronics technology follows Moore's Law and pursues smaller nano scale processes, so as to promote the development of integrated circuits to a higher degree of integration. At present, the electronic system integration technology integrates multiple functional modules to improve the integration density, which is the best method to combine the advantages of the two paths of continuing Moore's Law and surpassing Moore's Law. The RF microsystem adopts the micro nano heterogeneous integration process, integrating RF, digital, photoelectric, energy and other subsystems in a high density, so as to significantly reduce the volume and power consumption of the RF microsystem and improve the overall performance reliability.

Phased array antenna (PAA) technology is characterized by fast beam switching, high pointing accuracy and long operating range, based on which integrated electronic information systems such as radar, communication, electronic countermeasure, and data link, can be realized. As the core component of the active phased array, the RF microsystem has the function of transmitting and receiving RF signals,which is the best way to realize the miniaturization, thinness and conformability of the integrated electronic system represented by the PAA technology. RF microsystem technology is leading the subversive cequipment design methods and implementation means, which is an important means to achieve electronic information equipment.hange of equipment design methods and implementation means, which is an important means to achieve electronic information equipment.

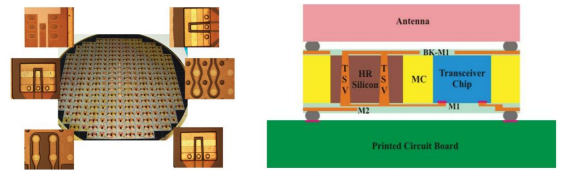

The research results of automobile radar released by Singapore S-STAR Research Institute show that it has realized a 77GHz automobile radar using TSV technology and embedded packaging technology, as shown in Figure 1.

Fig1

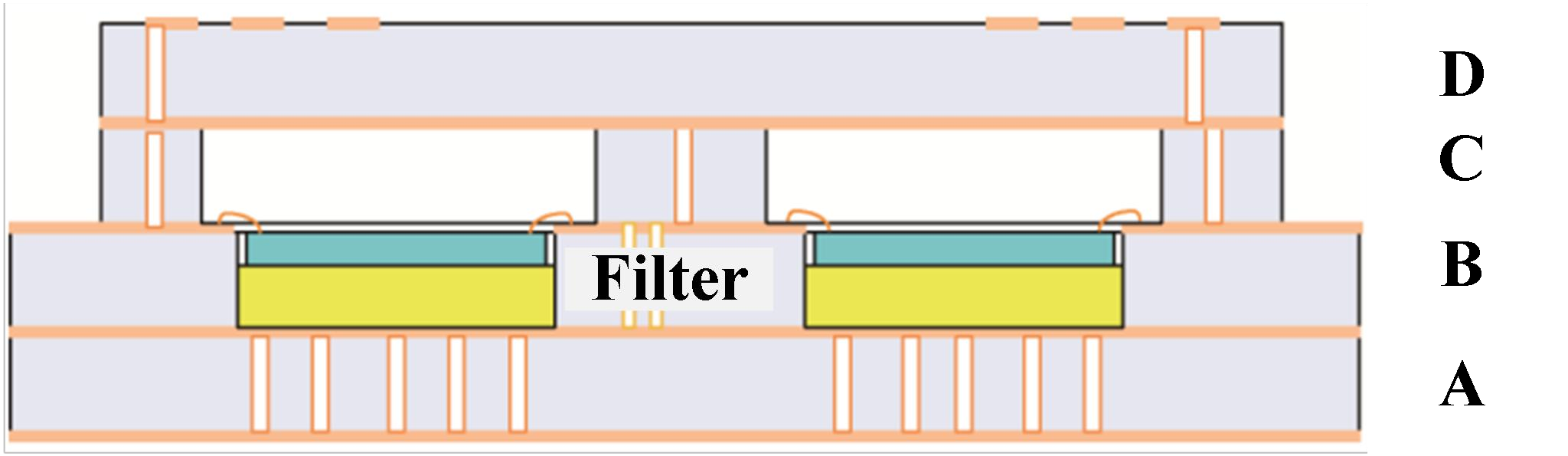

The SibSM RF microsystem utilizes silicon interposers for support,with surface-mounted core chips and wire bonding for signal readout , as depicted in Figure 5. The product is a broadband RF transceiver microsystem based on silicon MEMS technology, in which GaAs multi-function chip (MFC) and MEMS filter are integrated into one silicon chip. The overall size of this X-band RF transceiver module composed of four layers of interposers is about 25mm × 18mm × 1mm .

Fig5

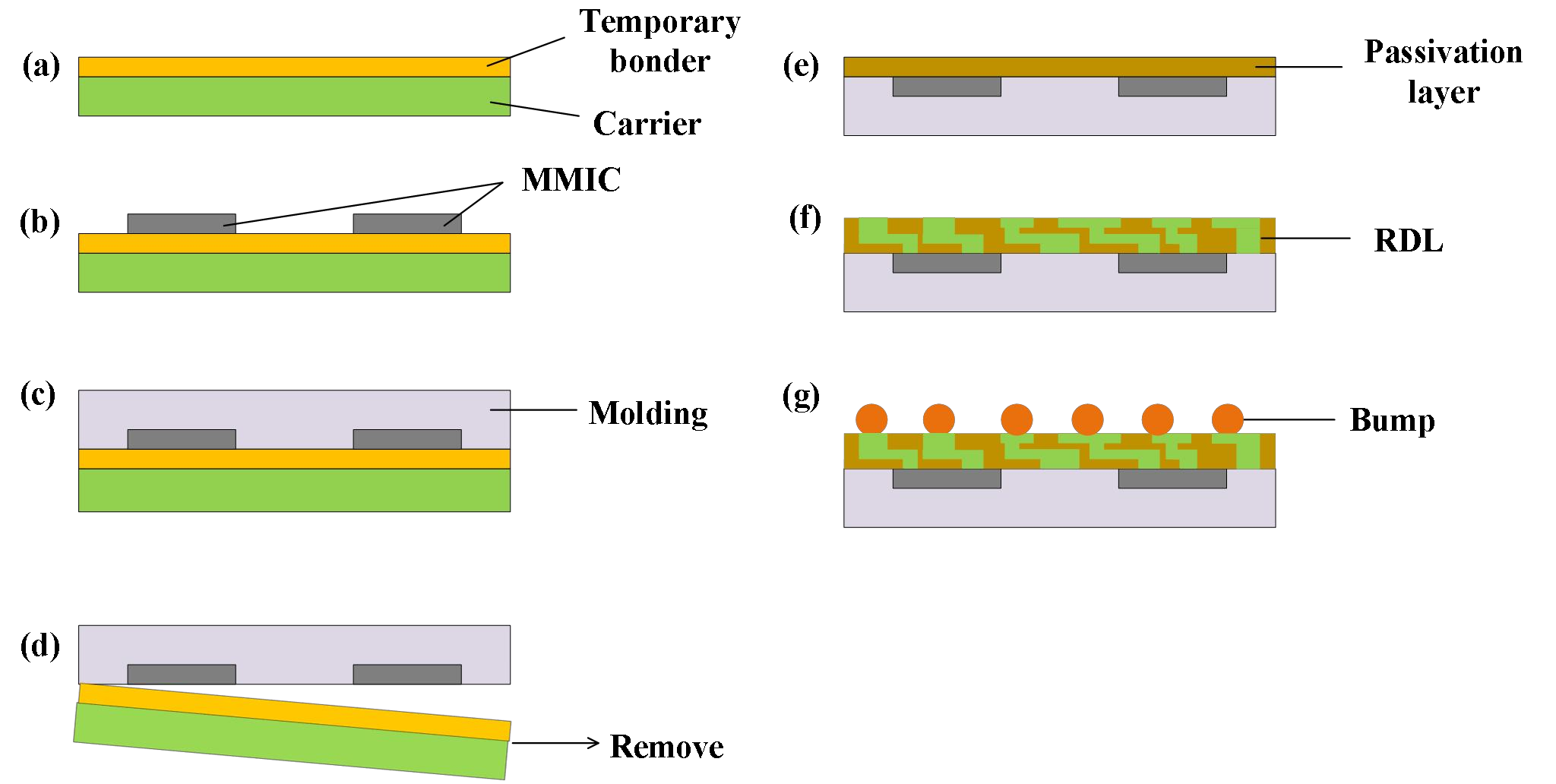

The Reb RF microsystem utilizes the fanout wafer-level packaging technique , which enables the placement of numerous RF and digital chips within a confined space through wafer reassembly. Subsequently, state-of-the-art manufacturing processes are employed to accomplish RDL and bump preparation. After dicing and separation, the package can realize electrical performance interconnection with external substrate.The Reb RF microsystem packaging technology can be categorized into three types chip first/face down,chip first/face up,and chip last packaging. A typical product with an overall dimension of about 27mm×27mm ×0.43mm and its packaging process which adopts the first one packaging technology are shown in Figure 12 and Figure 13., respectively.

Fig13

In summary,due to the limitation of the application of metal grounding on the back of RF chips,RF chips in RF microsystem packaging are predominantly oriented face up.As a result,the process technology for RF microsystem integration can be categorized into two methods: chip surface mounting and chip embedding.The application characteristics of the two packaging methods are shown in Table 1.

According to the comprehensive evaluation, the resin-based embedded chip package shows outstanding potentials in RF performance, integration capability, batch production capability and process cost. However, in terms of the universality of RF chips, metal grounding on the back of RF chips cannot be realized by this packaging, and special design of RF chips is required. At present, however, the universal chip with gold back grounding on the market cannot meet the requirements of the packaging process. Moreover, because of the high cost of customized chips, this packaging process is not suitable for small batch products. In addition, the resin-based package does not have the sealing function, thus reliability of the product still needs to be verified. In contrast, the silicon-based embedded chip package is as excellent as the resin-based products in chip versatility, RF performance, integration capability, batch production capability, etc., except that the manufacturing cost is high, and the yield should be effectively guaranteed in the manufacturing process.

In conclusion, this work describes the process architecture of RF microsystem integration technology. RF microsystems are categorized into three types based on different packaging substrate materials: silicon-based, ceramic-based,and resin-based. Ulteriorly, according to the way the chip is integrated into the package substrate, silicon- and ceramic-based RF microsystems can be classified into surface mounted and embedded types. By comparing the five typical packaging structures and their manufacturing methods, the application conditions of different packaging structures are clarified, which provides effective guidance for the development of RF micro system integration technology. RF microsystem packaging technology will find extensive applications as microsystem technology advances. But at present, RF micro-system packaging still faces many technical challenges, including electromagnetic shielding in the package, overall thermal management, manufacturing cost and long-term reliability. The above research needs to be strengthened to promote the further maturity and application of RF microsystem technology.

上一篇: 晶体硅的蚀刻

下一篇: 磁控溅射制备光滑SAC305薄膜