Abstract.

Current work describes development, testing and verification of a single wafer megasonic cleaning method utilizing a transducer design that meets the extreme particle neutrality, Particle Removal Efficiency (PRE), and repeatability requirements of production scale wafer bonding and other applications requiring extremely low particles levels.

Introduction

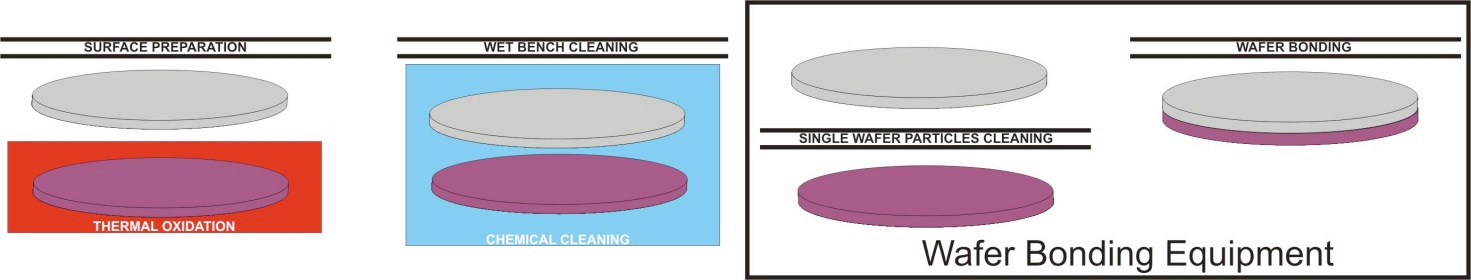

Different microelectronic processes require very clean surfaces in terms of particulate contamination. Among them, Direct wafer bonding has very aggressive requirement in terms of particulate cleanliness. Direct wafer bonding consists of joining together two materials by simply bringing their smooth and clean surfaces into contact (fig. 1). At room pressure and temperature, adhesion will be generated by Van Der Waals forces formed between the molecules/atoms at the surfaces of the two materials. As the two surfaces in contact are rigid, particles trapped between the surfaces generate areas which are not in contact (un-bonded areas or voids) thus decreasing the yield. A particle with a diameter of 1 µm is known to generate a bonding defect (void) with a diameter of ~1 cm! In order to prevent this from happening a typical process step consisting of a single wafer cleaning process is integrated.

Figure 1. Schematical direct wafer bonding process flow. For the above reasons, wafer bonding is very strict in terms of substrate cleanliness. If for a postCMP cleaning process incoming wafers would show particles levels of thousands or tens of thousands that are removed by cleaning process down to hundreds or tens of particles per wafer, in case of direct bonding the particles levels required for successful and reliable wafer bonding are in the range of less than 10 particles per 200 mm or 300 mm diameter wafers (particle size >0.12 µm). With such success criteria the efficiency of this novel cleaning method has to be qualified also by particles neutrality. Studied here as an application for direct wafer bonding, the MegPie® process may also be fine tuned to fulfill the cleaning and throughput requirements of other critical applications (thermo-compression bonding, epitaxy, layer deposition, lithography).

Experimental

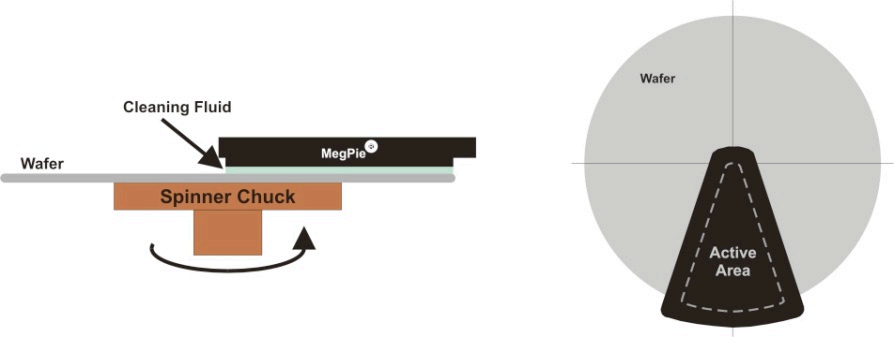

Apparatus. Two different models of a radially uniform area megasonic transducer, the MegPie®, were used in these experiments (fig. 2). This transducer couples acoustic energy into a fluid filled gap formed by the substrate and the transducer face. The form and resonator design assure uniform acoustic dosage over the entire surface of the rotating substrate without scanning motion. Constant monitoring of forward and reflected RF power as well as PZT crystal temperatures, assures consistent and repeatable acoustic processing conditions.

Figure 2. Single wafer cleaning system based on MegPie® transducer: a. schematical setup, and b. example of a V3 MegPie® model integrated on a production wafer bonder.

Initial testing was performed using a V2 MegPie® with a Teflon® PFA (perflouralkoxy) coated resonator. PFA coating is meant to provide a metal-free surface while assuring compatibility with the various chemical solutions used in wafer cleaning and etching. The PFA coated V2 MegPie® had been adopted for post CMP and other high particle count cleaning steps that had previously been accomplished with conventional brush or nozzle devices. While the PRE achieved with the V2 MegPie met the requirements of high particle count cleans, testing to the very demanding particle level and size specifications of direct wafer bonding exposed some issues with PFA coated resonators. It was found that PFA material is not particle neutral when megasonic energy is applied, and PFA coating itself was actually found to generate sub 100 nm particulate, therefore not acceptable for this pre-bond cleaning application. The PFA coated resonator was also proven to be very sensitive in that it could be scored or breached easily through contact with a hard substance, for example a broken wafer fragment. A score or breach of the material will, in best case, provide a source of additional particulate, and in worst case expose the underlying metal resonator to the process fluid.

上一篇: 湿法清洗中颗粒去除的新概念

下一篇: 使用臭氧技术去除光刻胶