As the semiconductor industry shifts from 200- to 300-mm wafers, the use of ozonated deionized water (DIO3) in surface cleaning processes is expected to become common. The technology, which has the potential to lower operating costs while maintaining process capabilities, has been widely studied, with particular emphasis on its application in photoresist removal after dry etching or ion implantation.1–6 Most photoresist removal procedures consist of a combination of plasma-induced dry ashing and wet chemical treatments. Problems associated with the dry ashing process include incomplete resist removal and undesired by products caused by the reaction among the photoresist, oxidizing gas, and dry etch residue. However, an even greater concern is the undesirable effects on electrical properties, such as intrinsic total charge to breakdown (QBD) and electrical breakdown fields, that can be caused by plasma-induced damage to sub-0.18-µm devices with a gate oxide of <40 Å. In addition, the oxidation reaction that occurs between the etch residue and the oxidizer gas in the plasma chamber during dry ashing creates residue that is difficult to remove in subsequent wet cleans. Traditional wet cleaning processes rely on a mixture of sulfuric acid and hydrogen peroxide (SPM) or sulfuric acid with ozone (SOM). Although these chemicals are highly effective, the operating costs for sulfuric-based processes are significant.7 Vast amounts of DI water are consumed to rinse off residual sulfuric acid and unoxidized particulate matter from wafer and carrier surfaces during the wet cleaning process, and expenses are incurred both in obtaining the water and treating and disposing of postprocess wastewater. Other operating costs include the expenses involved in the storage, distribution, and treatment of sulfuric acid mixtures and in the frequent replacement of wet station components. Such components have limited life spans because of their constant exposure to high process temperatures—generally >130°C—and the corrosive properties of the acid.

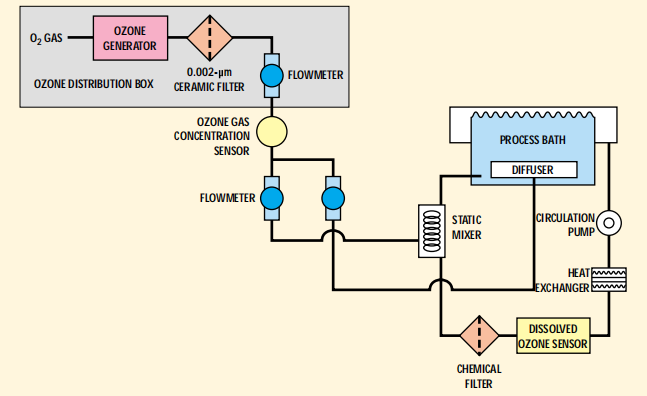

The flow scheme in the DIO3 immersion equipment is shown in Figure 2. In this system, ozone is produced from O2 gas in an ozone generator and fed into a static mixer, where it is combined with DI water. This mixture is then fed into the bottom of the process bath. Gaseous ozone is also fed in a uniform stream to the bottom of the process bath via a specially designed diffusion device. The gaseous and dissolved ozone enter the bath simultaneously, and both are monitored using in-line analysis. With closed-loop recirculation, liquid flows from the process vessel to a pump, after which it flows through a heat exchanger, a sensor, and a filter back to the mixer. Finally it reenters the vessel. In this system, the dissolved ozone concentration stabilizes in the range of 10–50 ppm, depending on the process temperature (which can range from 18° to 50°C).

上一篇: 高效单晶圆清洗工艺

下一篇: 堆叠结构的晶圆及其减薄方法