In this research, we conducted a series of experiments to investigate the mechanisms of chemical mechanical polishing (CMP) of silicon. Experimental approaches include tribological tests of frictional and lubricating behavior, chemical analysis, and surface characterization. Specififically, the effects of pH in slurry, surface roughness of wafers, and nano-particle size on removal rate were studied. A transmission electron microscope (TEM), a scanning electron microscope (SEM), and x-ray characterization tools were used to study the change of surface structure and chemistry. Experimental results indicate that the removal rate and planarization are dominated by the surface chemistry.

Key words: Silicon CMP, tribology, surface analysis

INTRODUCTIONChemical mechanical polishing (CMP) has been the primary planarization method for manufacturing integrated circuits for more than a decade.1–3 Chemical mechanical polishing is used to planarize the wafer surface and at a number of intermediate stages, and as a fifinal step after deposition of various features, interconnects, and coatings. There is little room for error during CMP because insuffificient planarity can result in diffificulties with subsequent process steps.4 Planarization can be achieved by several methods other than CMP, for example, the etch-back method, essentially a “negative” of the original photolithographic deposition of the features on silicon. However, the CMP process has been proven to be the planarization process of choice because it produces better results for smaller length scales. It has also been used to polish rigid disks in the magnetic memory industry. Materials removed in CMP such as W, Al, Cu, Si, and SiO2, as well as silica’s variant in forms of plasma-enhanced tetraethyl ortho silicate (PETEOS), boro phospho silicate glass (BPSG), and noble metals, are of industrial importance. There has been tremendous effort put into studying the CMP process formetals and dielectrics.5,6 For metal polishing, the dominant mechanisms are related to passivation and removal of tungsten,7 slurry viscosity,8 and electrochemical interaction.9 The contact between the pad and wafer10–15 and other systematic approaches have been reported. The polishing mechanisms of silica have been studied as has the formation of silica triggered by friction forces.16–19 Humidity causes the formation of a layer of amorphous SiO2 on a Si3N4 surface under friction. Such SiO2 molecules can be dissolved by the interaction of frictional stresses and chemical attack in water. Further experiments indicated that a competition between the oxidation and wear was possible. In this work, the authors revisited the polishing of silicon. A unique approach with the tribological investigation combined with surface analysis to explore the effects of particle and slurry chemistry on removal mechanisms and planarization was used. The objective of this work is to study the mechanisms of chemical mechanical removal of silicon using slurries containing either alpha or gamma nano-sized alumina particles. We investigated the performance of nano-alumina particles, and also the effects of pH, silicon dissolution and polishing, and silicon dioxide formation and polishing. Surface analysis was conducted using high-resolution transmission electron microscopy in order to detect the nature of nano-scale surface features after CMP.

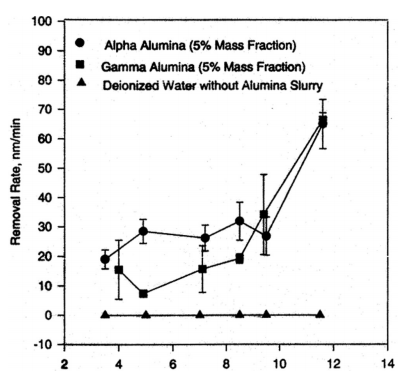

Fig. 1. The pH effect on the removal rate (nm/min) of silicon wafer is measured as a function of pH.

上一篇: 表面粗糙度对晶圆直接键合的影响