ABSTRACT

Micro-optics is an indispensable key enabling technology (KET) for many applications today. The important role of micro-optical components is based on three different motivations: miniaturization, high functionality and packaging aspects. It is obvious that miniaturized systems require micro-optics for light focusing, light shaping and imaging. More important for industrial applications is the high functionality of micro-optics that allows combining these different functions in one element. In DUV Lithography Steppers and Scanners an extremely precise beam shaping of the Excimer laser profile is required. High-precision diffractive optical elements are well suited for this task. For Wafer-Level Cameras (WLC) and fiber optical systems the packaging aspects are more important. Wafer-Level Micro-Optics technology allows manufacturing and packaging some thousands of sub-components in parallel. We report on the state of the art in wafer-based manufacturing, testing and packaging. Keywords: Micro-optics, microlens array, diffractive optical elements, wafer-level optics, wafer-level packaging, beam shaping, fiber coupling, array illumination, Shack-Hartmann, confocal microscope, slow-axis collimator.

INTRODUCTION

Micro-optics is regarded as a relatively novel technology. Most research institutes dealing with micro-optics were established in the 1980s or 90s. The first companies for manufacturing micro-optics were founded about 10 years later as spin-off from these research institutes. Still today the supplier’s base for micro-optics is relatively small. Micro-optics remains to be a niche product, not a big business. Micro-optical elements are refractive, diffractive, reflective or hybrid optics. Diffraction, scattering and interference effects at micro-optical elements could be quite complex: Moiré effects in stacked microlens arrays, intensity modulation in laser beam shapers, ghost images of diffractive optical elements, speckles – only some of the possible problems using micro-optics. In addition, the standard optical design software often does not allow simulating and modeling the optical properties of these elements correctly. Micro-optics requires special metrology tools for characterization and testing. System integration follows different rules than the classical optical components like lenses, prisms, beam splitters, etc.. The overall performance of a device using micro-optical components is often not exactly predictable during the design phase. Thus, micro-optics remains somewhat “exotic” for many optical designers and engineers. But, micro-optics has much to offer. Micro-optics allows to precisely shaping illumination light for imaging and projection system. Micro-optical fiber couplers, gratings for wavelength multiplexing and switches are essential key components for high-speed communication systems. Micro-optics allows to manufacture thousands of high-quality miniaturize systems on one wafer at very attractive costs. Endoscopes using graded-index microlenses have enabled micro-invasive surgery. The list of examples where micro-optics is an indispensable key component is long. Interestingly this is not such a new phenomenon. Already some hundred years ago researchers invented devices and systems based on micro-optics. Most of these inventions failed, because no suitable manufacturing technology for the micro-optics was available. In the following we will explain how semiconductor industry finally allowed manufacturing micro-optics with high precision. We will report on recent trends in wafer-level optics manufacturing, testing and packaging and present typical applications.

2 THE HISTORY OF MICRO-OPTICS

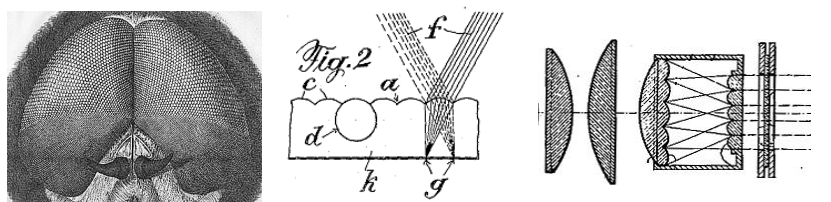

First micro-optical elements were manufactured by Antonie van Leeuwenhoek (1632 – 1723), a pioneer of microscopy and microbiology. Leeuwenhoek melted small rods of soda lime glass in a hot flame to obtain high-quality glass spheres. These ball lenses improved the resolution of his microscope viewers beyond current limits. He was the first to observe and report about single-cell micro-organisms. Another pioneer of microscopy, Robert Hooke (1635 – 1703), published his famous book “Micrographia”, a collection of microscope observations, in 1665. Amongst them is the fascinating drawing of a fly’s compound eye shown in Figure 1 (left), a natural microlens array. In fact, first natural microlens arrays appeared already in the Early Cambrian period, some 500 million years ago. Trilobites, a fossil group of marine arthropods, had complex compound eyes with microlenses made of calcite. Still today, similar compound eyes are found in many small creatures. Microlens arrays seem to be the appropriate solution for miniaturized vision systems in Nature.

Figure 1. (left) Image of a fly’s eye from Micrographia by Robert Hooke, 1665; (center) enlarged view of cylindrical microlens array on a photographic plate for integral photography, proposed by Walter Hess, 1912 [ 4 ]; (right) fly’s eye condenser for illuminating a film with uniform light as proposed by Mihalyi in 1927 [ 5 ]. The development of man-made micro-optics is much connected with photo- and cinematography. In 1891, Gabriel Lippmann (1845 – 1921) invented “interference color photography” [ 1 ]. He fixed a mirror in contact to the photographic emulsion and recorded the interference pattern from incident and reflected light in a sensitive but transparent emulsion. The Lippmann color photos, later referred as Lippmann holograms, were in fact first wavelength-selective volume holograms. For white light illumination, constructive and destructive interference generated the color image in reflection. Astonishingly, this invention was made without laser and long before Denis Gabor invented the holography in 1948 [2 ]. Lippmann also invented the “integral photography” an auto-stereoscopic method to display 3D images for observation with the naked eye [ 3 ]. Integral photography uses an array of small microlenses to record multiple sub-images of a scene in a photographic layer. Each microlens acted like a miniaturized camera recording an individual sub-image. Observing the developed photo plate through a similar lens array, the superimposed sub-images form an auto-stereoscopic integral image, a 3D image. In 1912 Walter Hess [4 ] proposed to use an array of cylindrical microlenses as shown in Figure 1 (center). These 3D displays based on cylindrical microlens arrays are later referred as parallax panoramagrams. Today’s 3D postcards and most of the new 3D television screens are based on this principle.

上一篇: 光刻微光学工艺

下一篇: 晶圆级制造的热气动可调微透镜