We have developed a self-contained, liquid tunable microlens based on polyacrylate membranes integrated with compact on-chip thermo-pneumatic actuation fabricated using full-wafer processing. Silicone oil is used as the optical liquid, which is pushed or pulled into the lens cavity via an extended microfluidic channel structure without any pumps, valves or other mechanical means. The heat load generated by the thermal actuator is physically isolated from the lens chamber. The back focal length may be tuned from infinity to 4 mm with a maximum power consumption of 300 mW. The principal application is fine tuning of the back focal length, for which tuning time constants as small as 100 ms are suitable.

Keywords: optofluidics; thermo-pneumatic actuation; tunable microlens; wafer-scale fabrication

INTRODUCTION Miniaturization of tunable lenses for integration into optically reconfigurable optical microsystems is promising for many applications, including optical communications, consumer electronics and medical engineering. Tunable lenses using electro-wetting1 or liquid crystal technology2 are available commercially; however, high voltages are typically required in such systems. Polydimethylsiloxane membrane lenses, operated by pumping an optical liquid into or out of a lens cavity, are of interest because of their low fabrication cost and easy implementation of a variety of actuation mechanisms,3 such as pneumatic, piezoelectric,4 electromagnetic5,6 and thermal actuators.7 However, limitations in the selection of liquid and membrane materials restrict the development of new actuation mechanisms, particularly from the standpoint of wafer-level microelectromechanical systems manufacturing processes. We present here a completely self-contained, thermo-pneumatically tunable microlens with on-chip actuation, fabricated using microelectromechanical systems techniques in a full-wafer fabrication process. The tunability is achieved by heating air in a pressure-generating chamber, which is connected via a meander-shaped channel to a liquid-filled optical chamber bounded by a polyacrylate membrane without using any actuation membranes, valves or mechanically movable parts. This method benefits from low driving voltages, but yields high pressures, inducing a large deflection of the surface of the tunable lens resulting in a wide focal length tuning range. In comparison to previous work on integrated thermo-pneumatically tunable microlenses,8 the concept presented here is considerably more compact and robust, with significantly improved thermal isolation between the actuator and the optical path. In addition, the present concept allows wafer-level fabrication, implying a lower potential cost due to improved yield.

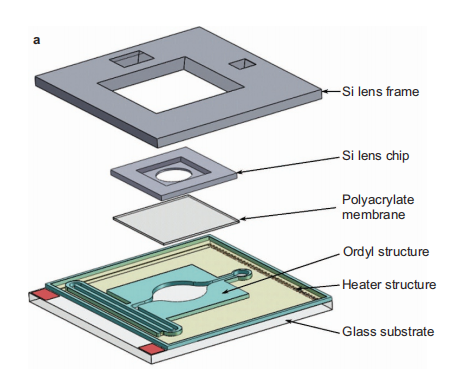

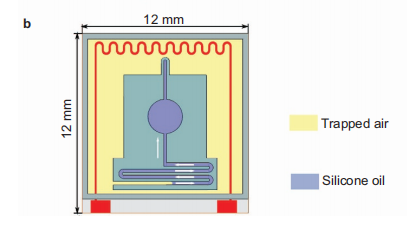

LENS DESIGN Figure 1a presents an exploded view of the fully integrated thermopneumatic microlens, which consists of five major parts; the corresponding thicknesses are given in parentheses. From top to bottom, these are: a silicon lens frame (500 mm), a silicon lens chip (300 mm), a flexible polyacrylate membrane (50 mm),9 a dry film resist (DFR; Ordyl) layer forming microfluidic structures and a glass substrate (500 mm) with heating and temperature sensing structures. Three rectangular openings are present in the silicon lens frame: one for filling the lens cavity with the optical liquid, one as a vent for removing air and the third for centering the silicon lens chip, which has a circular aperture 2 mm in diameter. A thin polyacrylate membrane, which defines the refractive interface of the lens, is sandwiched between the silicon lens chip and the fluid chamber. Using this approach, stable bonding is attained, and delamination of the membrane at the margins is prevented, even for the case of strong membrane deformation. The working principle of the microlens is based on the thermal expansion of air in the air chamber. As shown in Figure 1b, the air chamber is directly connected to the lens cavity via a microchannel that is filled with silicone oil as the optical liquid. When a voltage is applied to the heater, the rising temperature causes a volume increase, and the expanding air pumps the silicone oil through the meandershaped microchannel into the lens cavity. Because the liquid can be assumed to be incompressible, the volume increase of the expanded air will cause deformation of the polyacrylate lens membrane, thereby tuning the back focal length (BFL) of the lens. The dimensions of the air chamber and the channel structure are selected such that the expected volume displacement corresponds to the required BFL tuning range. The shortest BFL determines the required dimensions. In the present realization, the shortest

Figure 1 (a) Exploded view of the fully integrated thermo-pneumatic microlens. The red square areas at the left margin of the glass substrate are the electrical contact pads for the heater, which is on the opposite side of the glass chip (the wavy red line). (b) Top view of the microfluidic design. The liquid chamber and channel structure are filled with silicone oil (blue), and the outer larger chamber is filled with air (yellow). By heating the air, its volume increases and displaces the optical liquid in the channel. The displaced liquid is pushed into the lens cavity, thereby deflecting the polymer membrane, resulting in a change in the refractive power

appropriate BFL is approximately 5 mm. For a 2-mm diameter lens using silicone oil as the liquid with a refractive index of 1.4, the corresponding volume of the spherical lens cap is approximately 0.5 mm3 . The expanded air volume is not expected to directly transfer the same volume displacement to the optical cavity because air is a compressible medium. Thus, all repulsive forces—for example, capillary forces, viscosity or the repulsive forces of the membrane—will compress the air volume, leading to a small net volume change. Therefore, a buffer must be included in the fluidic layout. The designed lens has an air chamber volume of approximately 14 mm3 ; the theoretical thermal expansion of air at constant pressure is DV51.4 mm3 for a temperature shift of DT530 K, and the cross-section of the fluidic channel is 0.25 mm30.22 mm. Thus, to provide a volume expansion of 1.4 mm3 , a channel length of 25 mm is required. Owing to the small size of the microchannel and the resulting low Reynolds number, this device is resistant to shock and vibration during lens operation, and no liquid back flow occurs because capillary forces, surface tension and viscous forces dominate over gravitational forces in the laminar flow.

上一篇: 晶圆级微光学工艺

下一篇: 微透镜阵列的制作及应用